Multi-layer Biomass Automatic Integrated carbonization stove

| Condition:New | Type:Spontaneous Combustion | Place of Origin:Zhejiang China (Mainland) | Brand Name:Fusheng |

| Model Number:FS | Dimension(L*W*H):78*11*9.37m | Certification:ISO9000,CE | After-sales Service Provided:Engineers available to service machinery overseas |

| raw material:wood rod |

There are 3 types of carbonization kiln to making charcoal:

| types | cubage | Capacity (t) | Production period | Scope |

| Earth kiln | 14m2 | 2-2.5 | 20days | Charcoal |

| Machine kiln | 10m2 | 0.8-1 | 6-8days | Charcoal |

| Multi-layer kiln | 100-1000 | Charcoal, activated charcoal |

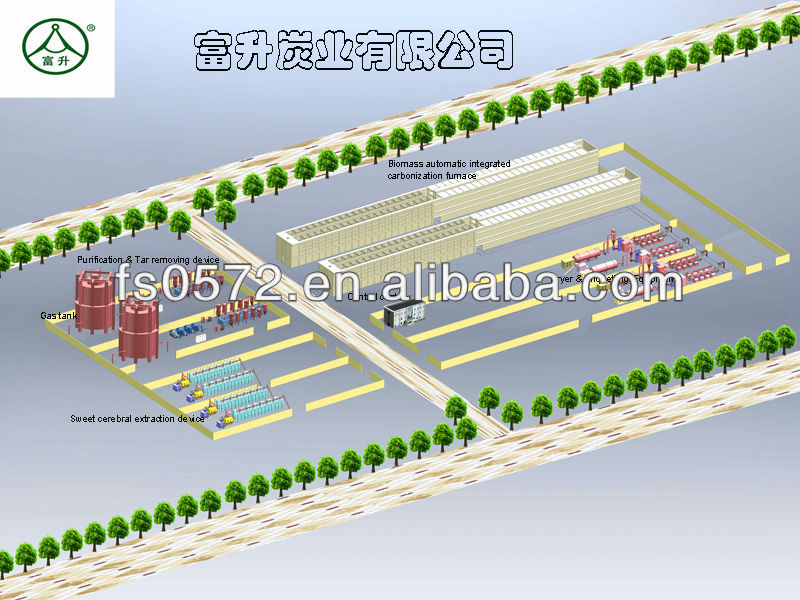

Multi-layer full-automatic integrated carbonization kiln

Patent number:[201220087211.X][ZL201120010971.6][200920302801.8]

The carbonization furnace is our newly developed integrated high-rise superposition carbonization furnace with full automation. The equipment can achieve full automation from rods into the kiln and out of the kiln. During the process, the combustible gas can be recycled over and over——we can collect the wood tar, pyroligneous, and the combustible gas after purification can be used to generate electricity. The design of the structure is very meticulous that we can take full advantage of the waste heat in the process of carbonization. In this way, the quality of charcoal is good and our high-rise superposition furnace is the world’s most advanced carbonization furnace currently.

Advantages:

1.It can produce 30-1000t charcoals per day and 15,000-5,000,000 KWH electricity.

2.The process is fully automated and can save 98% of labor costs.

3.The totally-enclosed structure can ensure the waste heat recovery.

4.During the whole process, there is no smoke and dust and can achieve the minimum discharge standard.

5.It can save 90% floor area compared with traditional carbonization kiln.

6.The quality of charcoal is very good.

Machine kiln for charcoal carbonization

Patent number:[ZL201029180024.4]

- The production cycle is 2-5days. The length of production cycle is related to the carbonization degree, and the carbonization degree affects the quality of charcoals.

- It has a capacity of 3000kg machine-made rods.

- It can produce 900-1000kg machine-made charcoals.

- Type of cooling: the cooling is conducted out of the kiln.

- : use pipeline to collect the smoke

- Price: 6000RMB or so

Using double pipelines to collect smoke gas can extract combustible gas. The capacity of 10-30t machine-made charcoals can also apply to the combustible gas power generation project.

Earth kiln

- The production cycle is about 22 days.

- It has a capacity of 8000-9000kg machine-made rods.

- It can produce 2600-3000kg machine-made charcoals.

- Type of cooling: cool in the kiln

- Smoke exhausting method: use pipeline to collect the smoke

- Price: 4500RMB or so

| Packaging Detail:Standard Export Packing |

| Delivery Detail:90 days after received the 30% prepayment |