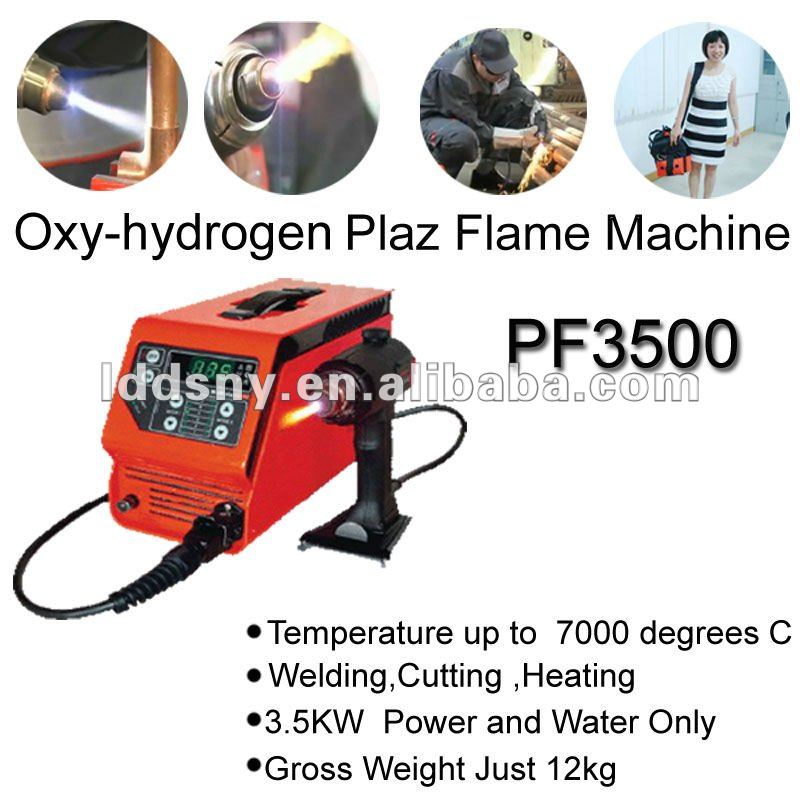

Multi-function Oxyhydrogen Plasma Flame Machine/Plasma Cutting Machine/Water Plasma Welding Machine MP3500

| Place of Origin:Hunan China (Mainland) | Brand Name:OKAY ENERGY | Model Number:MP3500 | Input Voltage:110V/220V |

| Rated Current:32A/16A | Dimensions:L380mm*W190mm*H140mm | Usage:Welding and Cutting | Color:Red |

| Is_customized:Yes |

1. What is water fuel oxyhydrogen plasma flame machine:

Water fuel oxyhydrogen plasma flame machine, also named oxy-hydrogen multi-function plasma welding and cutting machine, is a portable multi-function plasma welding,cutting,high-energy flame heating equipment.

2.The principle ofwater fueloxyhydrogen plasma flame machine:

The inner nozzle of shot gun (anode) and electrode (cathode) produce electric arc to make their water evaporate first and then produce ionization, form the plasma state of hydrogen ion, oxygen ion and oxy-hydrogen ion. Because of water in shot gun will become gas state from liquid state and then become plasma state, pressure goes up and will be bigger than outside atmosphere. So that plasma erupt from shot gun in terms of plasma beam, its temperature is up to about 8000°C, therefore non- flammable material can be cut, welded, brazed quenched, sprayed, heated, shaped and other forms of flame processing.

3. Features ofwater fuelOxyhydrogen Plasma Flame Machine:

Difference compared with normal air plasma cutting machine:

Normal plasma cutting machine | Okay Energywater fuel oxyhydrogen plasma flame cutting machine | |

| 1. | Need to compress air | Don't need to compress air, no need air compressor, transformer, gas cylinder and other auxiliary appliances |

In the same cutting thickness condition, water fuel plasma cutting machine power consumption is less. | ||

| 2. | No flame | Generating oxy-hydrogen flame, the temperature can be reached as high as 8000 degree |

| 3. | Generating powders in the process of cutting | It not only will not generate powders but also can prevent the powders from spreading. |

| 4. | Heavy | Light just 9kg, portable with its knapsack |

Difference compared with normal air plasma cutting machine:

Normal flame cutting machine | Okay Energy water fuel oxy-hydrogen flame plasma cutting machine | |

| 1. | Need oxygen cylinder | No need oxygen and air |

| 2. | Temperature just is 3400 degree | Temperature can be reached as high as 8000 degree |

| 3. | In general condition, it can't cut stainless steel,titanium plate, non-metal, quartz glass tube. | In general condition, it can cut stainless steel,titanium plate, non-metal, quartz glass tube. |

Water fuel oxyhydrogen plasma flame cutting machine:

1) Using water as material.

---No need any auxiliary equipment and no need industrial gas to do protection.

2) The power is convenient and energy saving.

---Our machine can be normal used in between110V to 253V voltage, a generator with 4kw/h can meet work demand when no power supply.

3) Safe and Environment-friendly

---No harmful gas produced, no any harmful to environment and operation person. And the ultraviolet ray is very weak, people can work just with No. 5 goggles.

4) Multi-functionality

---It can cut and weld various kinds of metal (such as carbon steel, alloy steel, cast iron, copper kind, aluminum alloy etc), and can weld, braze dissimilar metal, and can also cutting insulation materials, such as the quartz glass, ceramic, cement, stone etc non-combustible material.

3. Application ofwater fuel oxyhydrogen plasma flame machine:

(1) varied metals and nonmetals welding, cutting, heating and etc, such as light welding, copper tube of air-condition welding, battery welding

(2) automobile light steel processing, house operation, building decoration

(3) heating system, drainage system, power system, roof processing, refrigerator repair, exhaustion system and other installation and maintenance operations

(4) varied pipes operation, underground tunnel operation, ship's rail processing

(5) steel structural installation

(6) shedding, tapping, hole burning, welding and melting to surface, heating ferrous metal, non-ferrous metal, concrete and other material partly

(7) jewel processing, glass fabric processing precisely

(8) spraying and shaping to surface (such as edge quenching, concrete surface melting)

(9) metal structure anti-corrosion protection

(10) utilization of waste and other aspects.

4. Composition ofwater fuel oxyhydrogen plasma flame machine:

It is made up of plasma generator power supply, shot gun, electrical cable,dedicated portable shoulder bag for welder and related accessories.

5. Technical Parameters of water fuel oxyhydrogen plasma flame machine:

| PF3500 | AC Voltage Requirement | 110V/220V ±10% | |||

| Rated Power | 3.5kw/h | ||||

| Rated Current | 32A/16A | ||||

| Frequency | 50/60Hz | ||||

| Dimension- L*W*H | 380mm*190mm*140mm | ||||

| Weight | 8kg | ||||

| Torch Weight | 0.9kg | ||||

| Flame Temperature | 8000°C | ||||

| Welding Type | electro gas welding | ||||

| Steel Cutting Thichness | < 6mm | ||||

| Steel Cutting Speed | >7mm/s (when thickness of steel is less than 2mm) | ||||

| Steel Kerf | <1.5mm | ||||

| Liquid Consumption | <0.25L/H | ||||

| Packaging Detail:Standard Export Carton Packing |

| Delivery Detail:15-20 working days after 30% deposit |