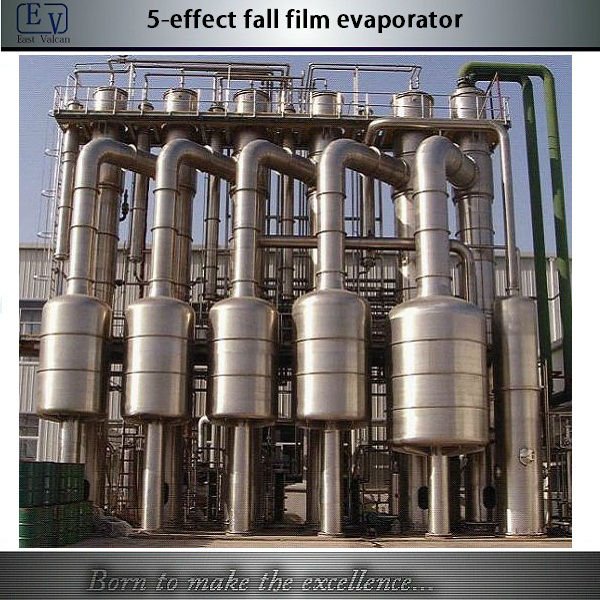

Multi-effect fruit juice concentrate

| Processing:Concentrator | Place of Origin:Zhejiang China (Mainland) | Brand Name:EV/DH | Model Number:5 effect |

| Processing Types:Juice | Application:concentrated juice, milk powder and so on | Material:SS. food grade | Style:Fall film |

Multi-effect fruit juice concentrate

Application:

This fall film evaporator is mainly used for concentrating or distillating the materials with low viscosity, good fluidity material, such as fruits or vegetable juice, glucose, starch, discharge liquid reusing, alcohol, syrup, milk industry etc...

It can get a higher heat transfer efficiency, short heating time, especially for heat sensitivity, treacliness and foaminess etc. Materials.

Components:

Every effect heating evaporator, every effect separator, condenser, high pressure pump, sterilizer, heat proof pipes, vacuum system, feeding pumps, condensated water discharging system, operation platform, elements etc.

Working principle:

The materials are separated by the separators, and distributed to every heating pipes, the gravitation and the second steam flow will make them as film, flowing from the upside to underside. The steam will heat the heating pipes, and exchange the heat with the materials, to make the water or other highly volatile material evaporated.

In order to ensure the materials get to the requested consistence by once pass, the heating room should have enough space, and at the same time, keep the flux of the materials, and by multi-effect evaporator to get this result.

Feature:

1-High thermal efficiency, shorter heating time, save the steam and power, and using less cooling water,

2-The materials are flow down along the inner wall of the pipes, the speed and pressure are increased, suited to concentrate the high viscosity products.

3-The materials in the heating pipes as film, the heated time is very shorter, it is specially good for foods concentration, to keep the nutrition of the foods.

4-It can cooperate with CIP cleaning system, can be cleaned on line automatically.

5-It can output the concentrated products continuously.

6-The evaporators can be assembled the automatic control system, to achieve the automatic control of input, heating temperature, output consistence, cleaning etc...It also can be assembled the protect system for power shutting and malfunction. And other safety and alarming operation and control.

Evaporating Type

| Falling film evaporator | Used for low viscosity, good fluidity material |

| Rising film evaporator | Used for high viscosity, poor fluidity material |

| Forced-circulation evaporator | Used for puree material |

For the characteristic of juice, we select the falling film evaporator. There are four types

of such evaporator:

Parameters:

| Item | 2 effects evaporator | 3 effects evaporator | 4 effects evaporator | 5 effects evaporator | |||

| Water evaporation volume (kg/h) | 1200-5000 | 3600-20000 | 12000-50000 | 20000-70000 | |||

| Feed concentration (%) | Depend on material | ||||||

| Product concentration (%) | Depend on material | ||||||

| Steam pressure (Mpa) | 0.6-0.8 | ||||||

| Steam consumption (kg) | 600-2500 | 1200-6700 | 3000-12500 | 4000-14000 | |||

| Evaporation temperature (°C) | 48-90 | ||||||

| Sterilizing temperature (°C) | 86-110 | ||||||

| Cooling water volume (T) | 9-14 | 7-9 | 6-7 | 5-6 | |||

Design of allocation material device:

| Packaging Detail:wooden case |

| Delivery Detail:50 days after deposite |