More professional heat-resistant wood chip dryer with production 10% improved

wood chip dryer, 1.Saving 10% energy, 2.Capacity 5% improved, 3.Adjustable speed motor2~10r/min, 4.Moisture(out) less than 8% - details see: https://www.machineto.com/more-professional-heat-resistant-wood-chip-dryer-with-production-10-improved-10287588

| Type:Drum Drying Equipment | Place of Origin:Henan China (Mainland) | Brand Name:Guoxin | Model Number:JZQ2.2*18m |

| Heat source:coal, electircity, gas,ect. | Gradient:3%-5% | Installation:under our technician's guidance | Service:for whole life |

| Color:blue, red, silver,vairous | Length:8-26m | Diameter:800-3200mm | Motor power:5.5-110kw |

| Heat:coal, gas, electricity | Raw material:boiler plate, stainless |

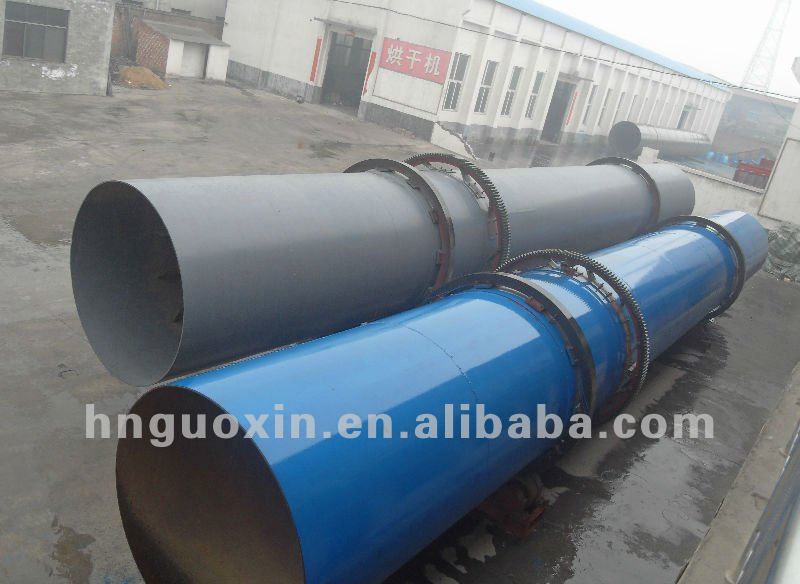

The features of wood chip dryer

- With the heat resisting, heat wearing alloy steel plates, it's life is 4 times as the common steel plates.

- Environment friendly reflected that thermal circulating system was equipped at its ending for full using the second heating power, which design give the heating second utilizing.

- Besides, energy saving shows that 1000kg of sawdust will spent 20-30 kilogram woods in this machine, while the same one should spent 70 kilogram woods in the common single pass drum dryer.

- The dryer is easy to operate and maintain, low energy consumption, high efficiency of drying and fine workmanship.

Technical paramete

diameter (mm) | Drum length (m) | Main reducer | Speed (r/min) | Production capacity (t/h) | Power (kw) | Weigh(t) | Volume(m3) | |

| Model | Ratio | |||||||

| Φ1000 | 10 | JZQ450-16-11 | 6.73 | 1-3.8 | 5.5 | 7.5 | 7.85 | |

| Φ1200 | 12 | ZL50-16-1 | 5.8 | 1.8-5.5 | 11 | 13.8 | 13.31 | |

| Φ1500 | 12 | JZQ500-111-2F | 16.46 | 4.8 | 4-9 | 15 | 22.3 | 21.2 |

| Φ1500 | 15 | ZQ50-1611-2 | 16.46 | 4.8 | 4-10 | 18.5 | 28.8 | 26.5 |

| Φ1800 | 14 | JZQ650-111 | 18.84 | 3.2 | 6-12 | 30 | 39.8 | 48.22 |

| Φ2200 | 16 | ZJQ750-111 | 31.5 | 3 | 10-23 | 37 | 51 | 60.1 |

| Φ2200 | 18 | JZQ750-111 | 31.5 | 3 | 10-25 | 37 | 53.3 | 70.43 |

| Φ2400 | 20 | ZL85-13-1 | 27.16 | 2.83 | 20-40 | 45 | 78.4 | 90.43 |

| Φ2800 | 24 | ZL100-16-1 | 31.5 | 2.59 | 20-45 | 55 | 97 | 147.8 |

| Φ3000 | 20 | ZL100-16-1 | 41.54 | 2.6 | 25-48 | 55 | 102 | 141.3 |

| Φ3200 | 25 | ZLH115 | 41.54 | 2.1 | 30-55 | 110 | 148 | 201 |

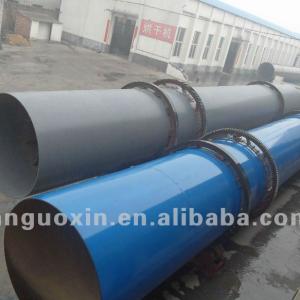

Working principle

- Humidity materials are conveyed from the feed screw directly into the drum, raised by the drum wall panels repeatedly, and scattered by the crushing blow dispersion device.

- Materials and the negative high-temp media are combined sufficiently to complete heat and mass transfer process. As the result of the drum wind angle and the induced air, the feed materials move slowly, and discharged from the spiral after drying, the exhaust gas handled by the dust precipitator, venting to the atmosphere.

Installation: slope 3%-5%

| Packaging Detail:Export standard container or as negociation |

| Delivery Detail:15~30 working days after prepayment |