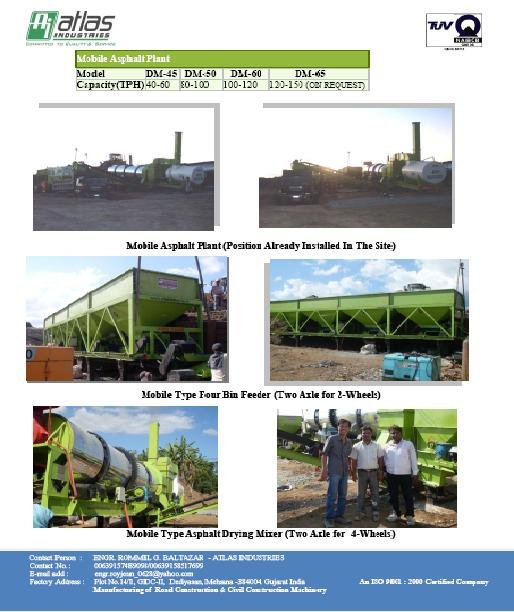

Mobile Asphalt Plant in Philippines

| Place of Origin:Gujarat India | Brand Name:ATLAS INDUSTRIES | Model Number:MDM50 | Capacity 60 to 90 tons per hoor:Mobile Type |

FOUR BIN FEEDER

All the four bins are fitted with individual A. C./ D. C. motors and gear box to control and regulate the flow of aggregate from each bin.

VIBRATING SCREEN

Gathering conveyor is equipped with scrapper and driven by A. C. motor. Aggregate from the gathering is fed to the drum with a slinger conveyor after removing oversize material. At the end of Four Bin Feeder, a rugged single deck vibratory screen is placed.

Its job: To remove oversized aggregate material.

CONVEYOR BELT

Driven by A. C. motor, aggregates are transferred to drying and mixing unit. It is equipped with weigh bridge (Load Cell) for continuous monitoring weight (tons/hour).

Its job: To weigh aggregate and transfer it to the mixing and drying unit

DRYING AND MIXING UNIT

Rotary cylinder drum mounted on sturdy platform driven by A. C. motor with sprocket and full chain equipped with high pressure jet burner, flights, bitumen and fines piping, frame mounted exhauster fan with high efficiency dust collector fitted with discharge dust screw conveyor.

This rotary dryer assures outstanding efficiency in heating and drying the aggregates because of the specially designed and arranged lifting flights. Uniform heating is given to each type of aggregate.

BURNER

High pressure jet burner with drying and mixing unit is capable of heating the aggregate to the required temperature without any un burnt fuel or carbon residue on the aggregate and to reduce the moisture content of the aggregate to minimum. The unit is also with suitable type of thermometric instrument fitted at proper places so as to indicate the temperature of exhaust gases, bitumen and mixture. For pressure Jet burner a suitable Fuel storage tank with fuel transfer pump is provided.

The low noise burner has sufficient capacity to cover the entire range of thermal energy required for drying

the aggregates with various type of fuel.

The combustion of the dryer burner satisfies the requirement of environmental regulations.

LOAD OUT CONVEYOR

The aggregate discharged from the drying drum is collected into an inclined load out conveyor (H. R.) equipped with G. O. B. hopper with hydraulically operated cam shell gate to provide surge capacity when changing trucks and controls segregation in the mix.

MINERAL FILLING UNIT

For addition of dust or mineral to the mix material in the mixing zone of the drying and mixing unit. It is provided with a rotary valve driven by

A. C./ D. C. motor. Filler material is conveyed to the drum through the drum through a pipe by suitable twin lobe compressor.

BITUMEN STORAGE TANK

Our storage tanks are mounted on a sturdy chassis. Storage tanks are cylindrical or U shaped. The tank is insulated with glass wool to avoid heat loss and reduce fuel consumption.

Automatic pressure Jet oil burner, bitumen pump with jacketed oil body, bitumen metering system with variable speed motor

and hot oil circulation motor is provided.

COMPUTERIZED PANEL WITH DIGITAL DISPLAY

Fully computerized cabin with on board electric power console, distribution, switch board, fully automatic process are a standard on ATLAS DM Series plant.

A software which is very user friendly ensures top notch performance. Display of the entire process control parameters.

Provision to store, edit production details, mix proportions, etc. Auto/ manual proportion.

CONTROL CABIN

Cabin is fabricated with M. S. Structured frame and insulated by wood.

Strategic location of seat ensures complete view of the plant.

POLLUTION CONTROL DEVICES

VENTURI TYPE Wet dust collectors are highly efficient and are known to maintain required environmental standards. The extreme turbulence leads to superb entrapping of dust laden exhaust gas.

Large size stainless steel nozzle provides a clog free operation to ensure optimum cleaning efficiency.

LDO STORAGE TANK

Our diesel tank are cylindrical shape and it is mounted on a sturdy chasis with high quality steel of M.S. Plate,

steel framing, with steel sealed cover on top to avoid filling of dirty materials and water inside the tank .

MOUNTING

All units suitably mounted on two chassis complete with axels, wheel hubs, trailer towing pins, etc.

WIRING

Pre wired with cables, socket, plug, junction box to interconnect the units

| Packaging Detail:FOUR FT. HC CONTAINERS ALL. A . 4 BIN FEEDERS 44TONS CAPACITYB. DRYING MIXING UNITC. BITUMEN TANK 20 TONSD. POLLUTION CONTROL DEVICEC. DIESEL TANKD. CONTROL CABINE. COMPUTERIZED DIGITAL SYSTEM CONTROL PANELSF. SENSOR G. WEIGHING CONVEYOR BELT/SLINGER CONVEYORH. VIBRATORY SCREENI. LOAD OUT CONVEYORJ. DUST COLLECTORK. MINERAL STORAGE HOPPERL. MOUNTING AND WIRINGS |

| Delivery Detail:25-30 days |