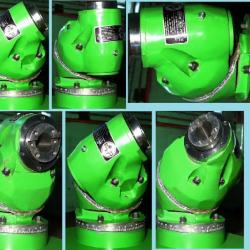

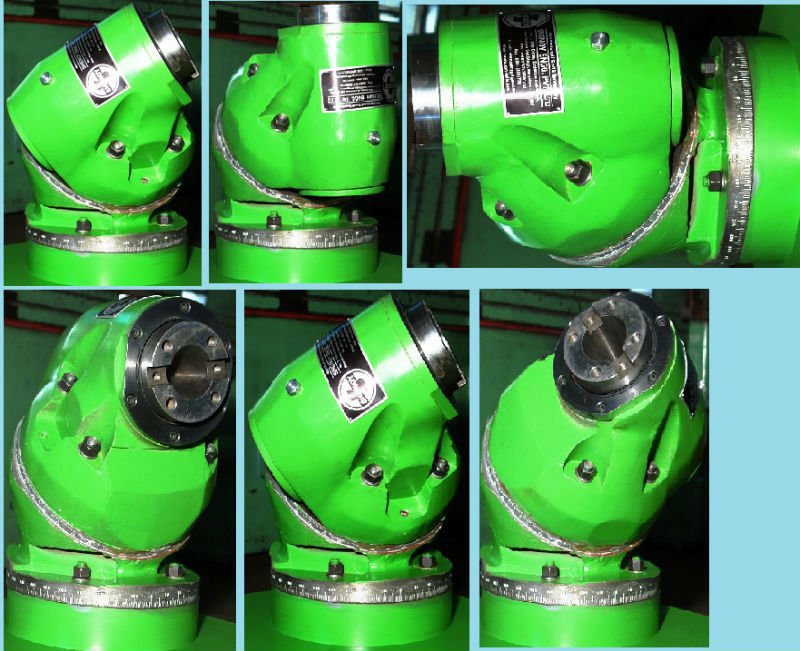

Milling head

Milling head, 1.Add multi angle, angular & universal milling, drilling capability to milling, boring machine. - details see: https://www.machineto.com/milling-head-10124420

| Condition:New | CNC or Not:Normal | Place of Origin:Karnataka India | Brand Name:Shenoy |

| Model Number:UMH-M | multi angle milling head:multi angle drilling head | angular right angle milling head:angular right angle drilling head | contour milling:contour drilling |

| spherical milling:spherical drilling |

Universal milling attachment is an import substitute, multi-utility attachment with spherical contouring and infinite variable orientation capabilities at any desired plane.

CONSTRUCTION, FEATURES & SPECS:

- Spherical contouring capability tot (a) to tilt±360° around the machine spindle axis (b) to tilt ±360° on its own spindle axis& & (c) to oscillate from front to back. In other words, the spindle of the universal head can be positioned at any desired angle – at circular planes or at oscillating plane or at a combination plane of both circular and oscillating positions.

- 2 pairs of spiral bevel gears and 3rotating shafts provide 360° variable, universal orientation facilities.

- Consists of 3 modules – flange, central module and vertical module.

- The flange module and central module have circular T slots, so that the spindle module can tilt on the central module and the central module can tilt on the flange module.

- While the flange and the central modules are with horizontal axes, the angle between the central and module and vertical spindle module has a unique 45° interface.

- The drive system consists of 3 shafts (including the spindle) with well-designed, rigid bearing supports and with 2 pairs of bevel gears.

- Pair of angular contact bearings in the front and a matched pair of angular contact bearings in the rear to rigidly support the ISO-50 spindle.

- Gears, shafts, spindles are made of case hardening steel, case hardened and ground.

- Adequately dimensioned, ground splines, integral with shafts & spindle for locating & rigidly supporting the spiral bevel gears.

- Spindle bearings are lubricated for life, using the molybdenum sulfide grease. For the gears, LS 415EP-00 grease is to be used.

- Body, consisting of 3 modules, is made of stress-relieved cast iron and conforms to Grade-25.

- Graduated collars with least count of 1°least count on the spindle and central module.

- Drive: through tennon

- Custom built flanges to suit to individual machines

- The ratio between input and output is 1:1.

- Conventional draw bar for arbor holding. Push button actuated hydraulic clamping and de-clamping of the cutter holding draw bar offered optionally.

- Recommended max. spindle speeds with standard taper roller bearing: 700 RPM

- Recommended max. spindle speeds with optional matched pair angular contact bearings: 1,000 RPM

| SPECIFICATIONS | UMH-L | UMH-M | UMH-E 40 x 40 | UMH-E 50 x 50 |

| Output spindle taper | IS0-50 | ISO-50 | ISO-40 | ISO-50 |

| Spiral gear module | 7 | 6 | 4.5 | 6 |

Cutter recommended (max) | Ø315 | Ø250 | Ø125 | Ø315 |

Suitable for spindle power | 50 HP & more | 30 HP | 5 HP | 50 HP & more |

| Packaging Detail:as specifiied |

| Delivery Detail:3 weeks with the tailor made flange (flange cost extra) |