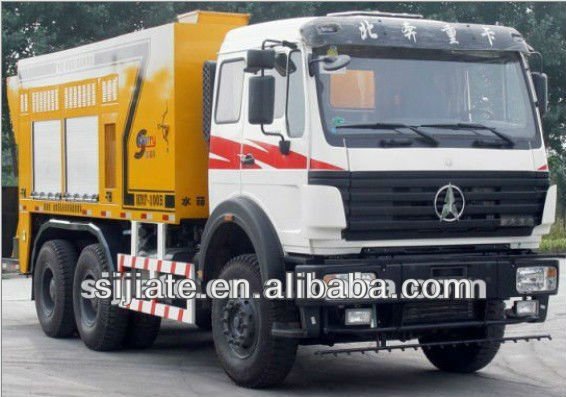

microsurfacing modified asphalt slurry sealer

| Place of Origin:Hebei China (Mainland) | Brand Name:Starry (sijiate) | Model Number:MA-HRF-100B8002 |

HRF100B is a very high cost performance hydraulic seal paver for pavement maintenance of high-grade highways, including surfacing and slurry seal. It is equipped with advanced and robust electro-hydraulic control elements to ensure stability and advancement of control and operation as well as precise mixing ratio of slurry compound and guarantee easy and correct control of construction quality by customers.

HRF-100B is applicable to modified (micro-surfacing) slurry sealing, for which modified emulsified asphalt is made with high polymer, e.g. SBR or SBS and featured in better high temperature stability and low temperature crack resistance. It is able to improve general performance of pavement and extend life span of pavement by applying modified slurry sealing. Furthermore, it is able to open for traffic within one hour after construction, which reduces traffic control after sealing. It is applicable to preventive maintenance construction of high-grade highway pavement and urban road as well as rutting repair and mixing of cold materials.

| Model | HRF-100B |

| Primary Use | Slurry Seal / Micro-surfacing |

| Aggregate Capacity | 10m3 |

| Emulsion Capacity | 2700 liters |

| Water Capacity | 2700 liters |

| Fines Feeder | 240 liters |

| Additive Tank | Stainless steel,280 liters |

| Production Rate | MAX 2500kg/min |

| Aggregate System | Belt conveyor, 24 inches wide, variable rear gate for calibration, steep hopper walls minimize bridging, automatic shut down of system when aggregate is empty. Hydraulic vibrator on hopper side. |

| Emulsion Pump Design | Variable Displacement, with heat jacketing, with emulsion strainer. Tri-Rotor Pump made by TRI-ROTOR from USA |

| Emulsion Pump Operation | Starts and stops with mix start switch or the pump switch |

| Mixer Type | Twin Paddle Shafts, adjustable pitch paddles with optional carbide tips. |

| Water System | Centrifugal pump for pugmill, spraybar and handhoses, follows speed of jackshaft to keep water ratio constant. Flowmeter display the water flux to the pugmill. |

| Additive System | Stainless steel tank, air pressure driven, additive injected into water stream |

| Material Control System | By one hydraulic driven jackshaft with electric clutches maintains the aggregate, emulsion and fines, need reading a graph of calibration before start working. |

| Engine | Cummins, 74kW (made in China) |

| Hydraulic system | Component from China |

| Control System | Program Logic Controller Automatic/manual operation |

| Flowmeter | Variable-area flow meter with glass tube |

| Truck shafts | 3 |

| Gross mass | 25,000kg |

| Wheelbase of the chassis | 4,450+1450mm |

| Comments for chassis | Long wheelbase and multiple axles for maximum weight capacity |

| Dimensions(L×W×H) | 9,526×2,500×3,260mm |

Our 20 years' expertise guarantees your 100% enjoyment and faith!

!!!Starry's service promise:

Before sales:

1.Gratis professional consultant service,multi solution options, and most suitable product recommendation.

2.Special product design and manufacture based on your requirements.

3.Gratis professtional technology consultant,and detailed equipment working scheme as reference,for your special project.

After sales:

1.Gratis professional technology training,to train qualified operator for you.

2.Satisfying solution response in 2 hours after your quality feedback.

3.Equipment repair warranty(details in contract attachment),life time repair service(only free of charge of labour cost).

4.Save your individual product records.

| Packaging Detail:Nude or as your requirements |

| Delivery Detail:within 1 month |