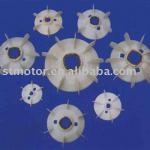

Magnet rotor

| Place of Origin:Zhejiang China (Mainland) | Brand Name:NEWLAND MAGNET | Model Number:Customized | Type:Rotor |

| Certificate:ISO9001:2008 and ISO/TS16949:2009 |

Magnet rotor:

1.Materials:Metal and sintered NdFeB magnet;

2.Technology:Utilizes new Sintered NdFeB magnet techniques and equipment such as strip casting, HDDR technology;

3.Magnetic properties:High coercive force, the max operation temp is up to 200 degree centigrade or 380 curie temperature;

4.Magnet Grades:with high performance NdFeB as H, SH,UH and EH for your choice.

5.Shapes and sizes:Various kinds or according to customers' request;

6.Coatings:Ni, Zn, gold, copper, exoxy, chemical, parylene and so on;

7. Applications:it is widely used in the motor part including AC motor, DC motor, drive motor, step motor and so on.

For your reference,we usually offer our "SH or UH" Grade Sintered NdFeB to other motor factories in Europe

who satisfied with our magnets.Morever,Our magnets are advantage in high stabilization and low weight loss.

The advantages of Stator Rotor:

1. They are customized, produced as per customers' designs and requirements.

2. Low cost and with high quality

3. Available of samples for your testing

4. we have engineers to instruct serial production

5. we pay attention to the products quality

6. Customized designs

Application for DC motor

High-speed rotor and high-torque

High-dimensional accuracy

Stator Rotor:

Precision-fabricated mild steel rotor with zinc plating

Rotor sub-assembly with nickel-plated neodymium magnets (skew available)

Precision-fabricated shaft (throughhole option, labyrinth option)

Drive (shaft/rotor) sub-assembly with permanent magnets

Integrated mild steel shaft/rotor sub-assembly (one piece) with permanent magnets

Magnets:

Custom permanent magnets for motor applications

Sintered Neodymium with various material grades

Segment shapes include Arc, Wedge, Skew

An example would be a NdFeB 35SH skewed arc with nickel plating

We will custom design and manufacture magnets for your OEM needs

Our technician will assemble Stator Rotor by himself.The quality will be controlled. We'd like to produce the samples for your testing before your mass order. Please feel free to let us know your specific inquiry.

Thanks for your consideration and cooperation!

| Packaging Detail:Standard air and vessel package or according to customers' request |

| Delivery Detail:10-20days |