magnesium titanate atomizer spray dryers

| Place of Origin:Jiangsu China (Mainland) | Brand Name:XIANFENG | Model Number:PGL400 | SUS304,SUS316L material:mirrow polish inside |

| ISO14001:2004:ISO9001:2008 |

1.Principle of Work

After filtering and heating, the air enters into the air distributor at the top of the dryer.The hot air enters into the drying chamber in the spiral form uniformly. By passing through the high-speed centrifugal atomizer at the top of the tower, the material liquid will be rotated and sprayed into extremely fine mist liquid beads. Through the very short time of contacting with hot air, the materials can be dried into the finished products. The finished products will be discharged continuously from the bottom of the drying tower and from the cyclone separator. The waste gas will be discharged by blower.

2.Dried Samples

Foodstuff :amino acid, vitamin, flavoring, protein, dried milk, pig blood powder, soy powder, coffee, tea powder, glucose, potassium sorbate, pectin, essence, vegetable juice, yeast, starch etc.

Ceramics:alumina, zirconia, magnesium oxide, titanium oxide, magnesium titanate, pottery clay, china clay, all kinds of magnetic porcelain and metal-oxides etc .

Chemical Products:dispersed dyestuff, active dyestuff, organic catalyst,white carbon black, detergent powder, zinc sulfate, sodium metasilicat, potassium fluoride,calcium carbonate, tribasic potassium phosphate, inorganic catalyst and all kinds of waste liquid

3.Technical Parameters

| L PG Item | 5 | 25 | 50 | 100 | 150 | 200 | 500 | 800 | 1000 | 2000 | 3000 | 4500 | 6500 | ||||||

| Inlet temperature(°C) | 140-350 automatically controlled | ||||||||||||||||||

| Outlet temperature(°C) | 80-90 | ||||||||||||||||||

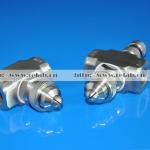

| Way of Atomizing | High Speed Centrifugal Atomizer (mechanical drive or stepless frequency speed regulation is available) | ||||||||||||||||||

| Water evaporation capacity(kg/h) | 5 | 25 | 50 | 100 | 150 | 200 | 500 | 800 | 1000 | 2000 | 3000 | 4500 | 6500 | ||||||

| Revclution of atomizer(rmp) | 35000 | 20500 | 17600 | 15500 | 11570 | 10983 | |||||||||||||

| Diameter of Atomizing disc (mm) | 50 | 108 | 120 | 130 | 150 | 190 | 210 | 240 | |||||||||||

| Max Electric Heating Power(kw) | 15 | 36 | 63 | 81 | 99 | Use other heat source | |||||||||||||

| Dried Powder Recovery Rate(%) | Around≥95 | ||||||||||||||||||

| Length of Covered Area(m) | 1.6 | 4 | 4.5 | 5.2 | 7 | 7.5 | 12.5 | 13.5 | 14.5 | Decided in accordance the flow chart, condition of field and requirement of customers | |||||||||

| Width of Covered Area(m) | 1.1 | 2.7 | 2.8 | 3.5 | 5.5 | 6 | 8 | 12 | 14 | ||||||||||

| Height of Tower Body(m) | 1.75 | 4.5 | 5.5 | 6.7 | 7.2 | 8 | 10 | 11 | 15 | ||||||||||

| Hoisting height of Nozzle(m) | -- | 2.5 | 2.5 | 3.2 | 3.2 | 3.2 | 3.2 | 3.2 | 3.2 | ||||||||||

Notes: The evaporated amount Of moisture is concerned with characteristics Of raw material, solid cont6nt and temperature of hot air at inlet and outlet. Customers can choose the heating way Of heat according to the conditions of local energy source. | |||||||||||||||||||

| Packaging Detail:nude put in container or box frame |

| Delivery Detail:after received deposit in 55 work days |