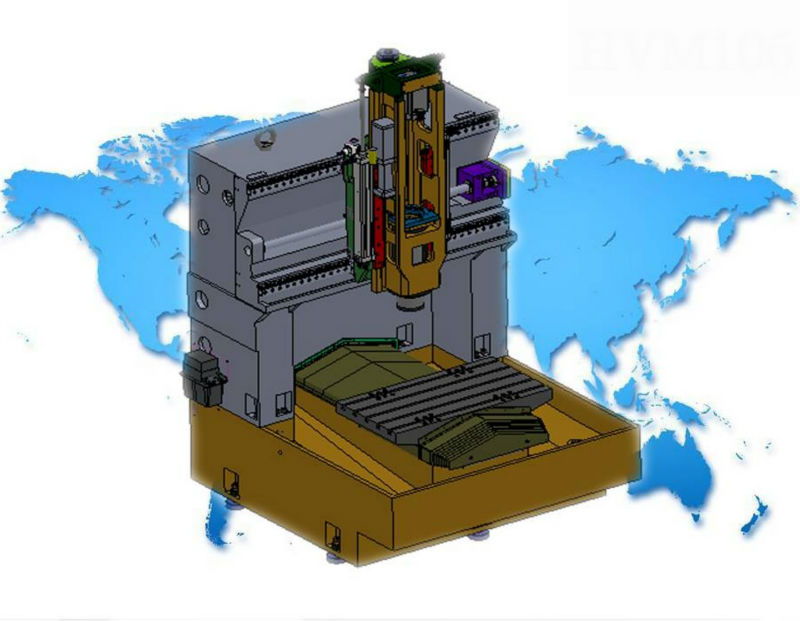

machining center frame HVM1060

| Condition:New | Place of Origin:Yunnan China (Mainland) | Brand Name:SMARTECH | Model Number:HVM106 |

| Type:Vertical | CNC or Not:CNC | Voltage:380 V | Power(W):12 kw |

| Weight:7600 kg | Certification:ISO CE | Warranty:one year | Supply Full Guarding:Follow client's requirement on Color and Painting |

| Cooperating Company:Fryer Machine System (American) |

SMARTECH CNC VMC FRAME

- MACHINE FEATURE:

1 High-class casting by resin sand and wood mould;

2 Top class imported ball screws sets and bearing ;

3 Imported spindle & tool clamping system ;

4 Imported drive connectors ;

5 Stainless steel telescopic protection on X/Y/Z axis ;

6 Central lubrication system ;

7 Coolant system ;

8 X&Y axes Linear slideways and Z axis box way type;

- OPTIONAL:

1 Spindle from Taiwan;

2 Direct drive structure for main motor with spindle ;

3 Central oil coolant for the spindle ;

4 Coolant through spindle ;

5 ATC: drum type, arm type or chain type ;

6 Outside guarding: standard or special made according to clients design

7 Chip conveyor

8 CNC pre-installed for clients: whole full ready package delivery according to clients design

- SPECS:

| MODEL | HVM106 |

| Table Size | 1120 x 600 |

| Travel X | 1050 |

| Y | 600 |

| Z | 550 |

| Spindle to Column Slideway | |

| Spindle Nose to Table Surface | 125-675 |

| T-Slot(No-size/distance) | 5-18/100 |

| Spindle Taper/outside dia | BBT40 |

| Spindle Speed | 15000rpm |

| X,Y axis Ball Screw Spec. | 50/20 |

| Z axis Ball Screw Spec. | 40/12 |

| X,Y & Z Motor Connection | Direct /Direct/Bell |

| Main motors recommended | 12kw |

| Drive motors recommended X/Y/Z | 27/27/16Nm |

| Table Work Load | 660 Kg |

| Net Weight | 7600kg |

1. C-sharp structure with column and beam molded together provides high rigidity and high stability.

With X axis in the beam, the worktable can move faster as the load in Y axis was lightened

The overhang of spindle house is of proper length so that the guide and spindle don’t have to bear unnecessary torque

2. Linearroller way in X, Y axes and box way in Z axis.

Given the length of X, Y axes and the loads on them, linear roller way is applied there for its load-carrying capacity and rapid response to CNC commands.

As Z axis travel is relatively shorter, box way with adequate lubrication is used here for its higher stiffness, good damping characteristics, and resistance to high cutting load.

3. Pneumatic counter balance system

The application of pneumatic system not just decreases wear on ball screws, but also ensure smooth, responsive and precise movement of cutter

4. The spindle can work at a speed of 15000 rpm. The BBT40 spindle taper can cooperate perfectly with both BT40 and BBT40 taper shanks to perform not just general processing but high-speed processing.

5. To attain optimum performance, every chief component has been analyzed with FEM

Application:

1. Machining 1). molds of Middle and small size

2). parts of cars, aircrafts

3). Parts of other precision-sensitive machines

2. In case that you might need a rotary table we have reserved room for 4thand 5thaxes

3. Parts of 3C products(3C refers to Computer, Communication & Consumter-Electronics)

Client Sample: Fryer Machine System

Country: America

Corresponding Model: HS-106

| Packaging Detail:Plastic film and wooden pallet |

| Delivery Detail:around 45 days |