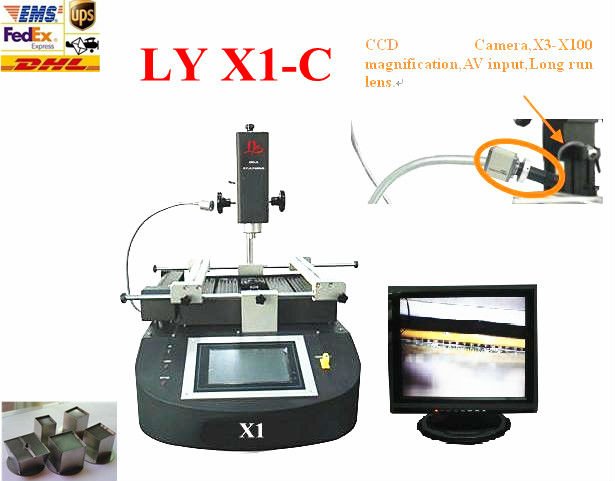

LY X1-C bga rework station,upgraded from HR360-PRO,HR460C,SP360C,5860C

| Place of Origin:China (Mainland) | Brand Name:LiYang (LY) | Model Number:X1-C | Input Voltage:VOLTAGE |

| Output Temperature:300 DEGREE | Temperature Stability:300 DEGREE | Output Power:3800W | Dimensions:55x55x50 |

| Model:X1-C | Brand:LiYang(LY) | Color:Black | Work model:Hot air |

| Power:3800W | Voltage:220V |

LY-X1C

REWORK STATION

SPECIFICATION

Shenzhen LiYang Welding Equipment LTD.

LY X1C,with CCD Camera System,the most cheapest 3 temperature

zones,touch screen,hot air model with CCD function in market.

Main similar models in market:

5860C

H460C

1.Product Profile

LY-X1Cis a style of rework station equipped with ARM (Advanced RISC Machines) control system and laser positioning that can repair all kinds of components in laptop & PC such as south-north Bridge Chip, VGA, cell phone, digital camera, projector and console games.

2.Product Description

2.1 Features

The control circuit of the whole machine with optimization design; power output and control system adoptphotoelectric isolation technology; antijamming capacity and security stronger;

ARM32 bit microprocessor and industrial color high-resolution 7 inch touch screen designed 2 in 1; system running speed quicker and more stable.

Upper and lower fan revolving speed can be adjusted from 0 to 100%, which is especially convenient for small BGA breeze soldering

High quality heating materials, produce high temperature breeze and precisely control BGA desoldering and soldering process.

Movable heating head; movable all around for easy operation;

Touch screen interface, real-time temperature profile display, can display the set profiles and the actual temperature profiles.

High resolution touch screen, convenient for operation and observation;

Upper/lower hot air, can control temperature precisely according to the temperature setting; Bottom IR constant temperature heating; reasonable temperature control makes rework safer and more reliable.

BGA support frame in soldering area, can micro-adjust the support height to prevent local soldering area from sinking.

Powerful cross flow fan, cools down the bottom heating areas quickly.

with multi-function PCB positioning supports, PCB location convenient and quick and suitable for irregular-shaped boards installation and location;

Hand vacuum pen, easy for picking up BGA away;

With different sizes of alloy nozzles, easy for replacement, and can be customized according to specific needs;

Equipped with laser alignment device,makes PCB location more convenient and quicker;

SSR operation display function, makes temperature control safer and more reliable.

Under different environment or in different areas, auto-generate standard SMT desoldering profiles; no need to set profiles by hands and users with repair experience or not can operate it easily.

Can support mini SD card: 1. can renew the language on operation menus; 2, can export temperature profiles parameters; 3, can import temperature profiles parameters

Technical parameter

PCB Size: L20*W20~L460*W370mm

BGA size: 2*2-60*60mm

PCB locating way: Outer or jig

Bottom pre-heating: IR 2400W

Lower heater: hot air 800W

Upper heater: hot air 600W

Power: single-phase 220V, 50/60Hz

Machine size: L620*W600*H650mm

Standard accessories

Nozzles: 5pcs

Lower big nozzle 1pcs, small nozzle 1pcs

Allen wrench : 1set

User manual: 1pcs

Brush: 1pcs

Suction nozzle: 1pcs

Thermocouple: 1pcs

Mouse: 1pcs

Aluminum plate: 1pcs

CCD camera system with Monitor

Fixture with pothook for abnormity boards |

SSR running display |

Laser pointer |

Net length: 37CM |

Net width: 29CM |

Knob for adjusting the height of upper head |

Handle for locking the upper head from moving forward/backward |

Knob for adjusting upper headup/down |

Lower nozzle designed with 5 points to prevent boards from deformation

Main operation interface

Saving parameters” interface

A

“Auto profile” interface

CCD Camera,X3-X100 magnification,AV input,Long run lens. |

| Packaging Detail:Woodern BOX |

| Delivery Detail:3-5 days |