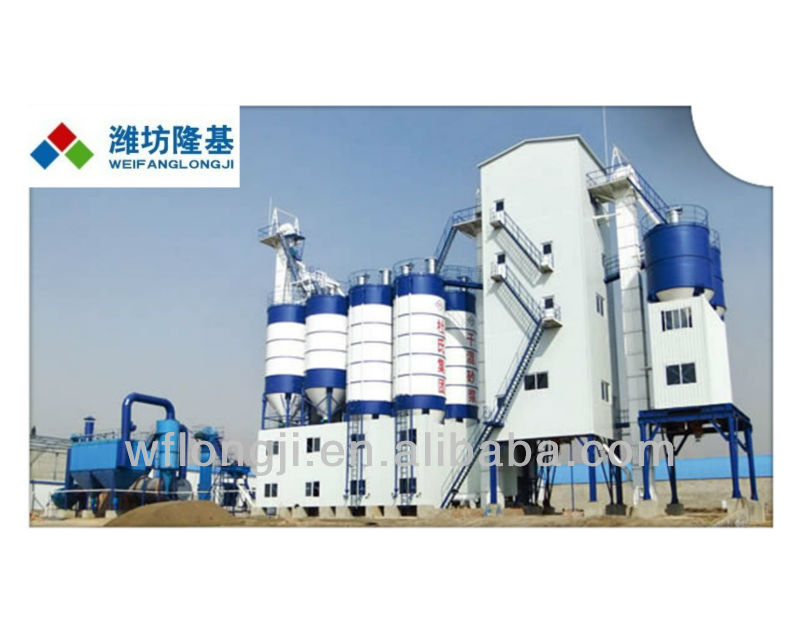

Lower Cost Full-auto Complete line for production of heat preservation mortar,Full-auto Dry Mixed Mortar Machine

| Place of Origin:Shandong China (Mainland) | Brand Name:WFLJ | Model Number:Vertical Type | After-sales Service Provided:Engineers available to service machinery overseas |

| full-auto:dry mortar production line | Vertical Type:Lower cost |

Dry-mix mortar production line with reasonable structure 1. In contrast to job-site mortars ,dry mortar is also called pre-mixed mortar ,which is produced in the factory with dedicated facilities on batching and blending of ingredients in highly-controlled process .It can be used directly just by adding water in job site . 2. It has advantages of consistent quality ,controlled inventory ,saving time and labor cost .By adding different chemical additives ,it has fine properties of bond ,thermal and acoustic insulation,crack-resistance ,workability , Water-retention,wear-proof,anti-corrosion,etc. 3. Dry mortar can match different kinds of new construction materials by improving formulation.These good properties not only improve building’s quality and life greatly,but also decrease the usage of mortar in a large degree. 4. The demand for dry mortar has increased rapidly due to its outstanding merit comparing with the mortar mad in job-site. | ||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||

Usage for Dry mortar production line: | ||||||||||||||||||||||||||||||

1. Adhesive mortar ,such as ceramic tile adhesive ,filler,heat preservation multiplexed system use adhesive mortar,etc. | ||||||||||||||||||||||||||||||

Raw Material: | ||||||||||||||||||||||||||||||

Main configuration of Workshop-type dry mortar production line: 1, Storage system 2, Metering and batching system 3, Conveying system for Raw material 4, Accurate and homogenous mixing system 5,Air compressor system 6, Accurate packing system and bulk handling technology 7, De-dusting equipments to protect the working environment 8,Advanced and reliable pneumatic control system 9. Monitoring system | ||||||||||||||||||||||||||||||

Service Promise : Notice: So if interested ,only send the detailes, under: Payment Terms and Conditions of dry mortar mixer 1. Quotation (EXW price with tax) is valid for one month . 2. Delivery time:30 days after receipt of your deposit. 3. Payment terms:30% T/T in advance, the left is paid (by T/T) before leaving loading port. If open L/C, there is 2% of L/C amount for bank charge. 4. Package: nude packing, with 40HC/20HC. 5. MOQ: one set |

| Packaging Detail:Seaworthy package |

| Delivery Detail:30 days |