Low Cost Stone Production Line With EXW Price

| Place of Origin:Henan China (Mainland) | Brand Name:Huaye | Model Number:Various | Condition:New |

| After-sales Service Provided:Engineers available to service machinery overseas |

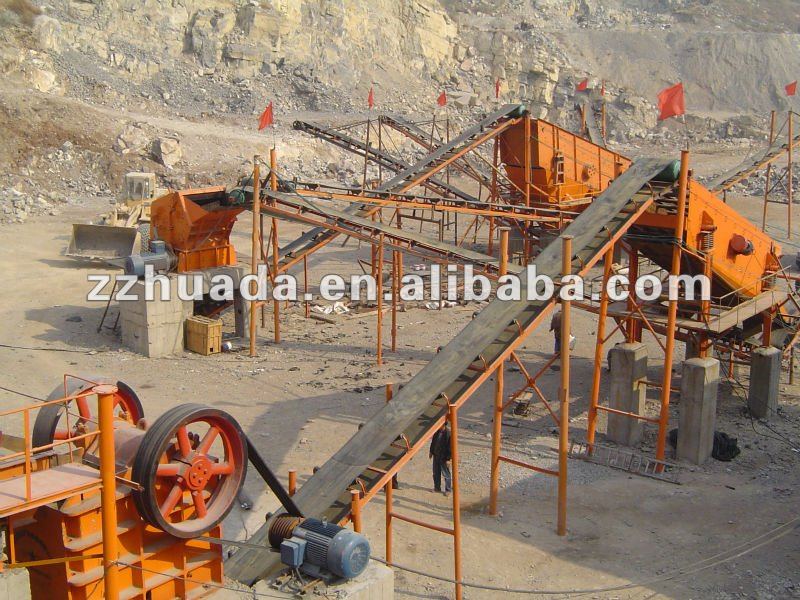

stone production line

Stone production line has a high degree of automation,big crushing ratio, high production efficiency, high Capacity, After a broken products are in cube shape, Needle flake content low, No inner crack,high compressive strength. The equipment maintenance is simple.Vulnerable parts adopt the newest high-strenght wearable materials at present domestic ,low consumption, long service life, can bring customers significant economic benefits .Stone crushing production line has been successfully applied in limestone, xuanwu stone, granite, pebbles and broken rock processing. The product quality completely broken to GB14685-2001 standard For the highway, railway, water conservancy, concrete mixing station provides qualified aggregate industries. Stone production line(Sand production line)special equipment is special equipment of the production of building sand and stone. Stone equipment includes jaw crusher, stone crusher, impact crusher, impact crusher, vibrating feeder, vibrating screen, sand washing machine, belt conveyor, etc

The process of stone production line roughly lists below:

(silo)-feeder-jaw crusher- -the impactcrusher-- vibrating screen ( finished products).

Between can be connected with conveyors.

Basic process of stone production line:

Stone is sent to the rough crushing machine for preliminary broken by feeder.Then,the rough materials are sent to impact crusher to further crushing by belt conveyor.The fine stone is sent to vibrationg screen to get different type of stone.the stones that doesn’t meet the requirements are sent back to the impact crusher to crusher again.

The property of stone production line

Stone production line has a high degree of automation.Except the equipment downtime and daily maintenance,the whole line almost doesn’t need artificial operation. The high production efficiency ,lower cost,big yield,high profit, even and good granularity of finished product, comply with the national high-speed materials requirements. Stone production line equipment configuration basically based on customers' requirements of stone specifications and yield of stone and application to determine. All the broken screening combination equipment in the process of design,due to reasonable matching crusher equipment at all levels,and the rigorous space cross layout,so it owns the characteristics of small coverage ,high investment profit,good broken quality,low output rate of quarry dust. At the same time equipped with the advanced electric control system operation.Ensure that the whole process discharges unobstructed, operation reliably, operated conveniently, high efficiency and energy saving

characteristic

1. Stone production line has a high degree of automation,big crushing ratio, high production efficiency, high Capacity, After a broken products are in cube shape, Needle flake content low, No inner crack,high compressive strength.

2. The equipment maintenance is simple.Vulnerable parts adopt the newest high-strenght wearable materials at present domestic ,low consumption, long service life, can bring customers significant economic benefits .

3. Stone crushing production line has been successfully applied in limestone, xuanwu stone, granite, pebbles and broken rock processing. The product quality completely broken to GB14685-2001 standard For the highway, railway, water conservancy, concrete mixing station provides qualified aggregate industries.

| Packaging Detail:Export standard or nude packing or as your request |

| Delivery Detail:40-60 working days after informing you pay the balance amount |