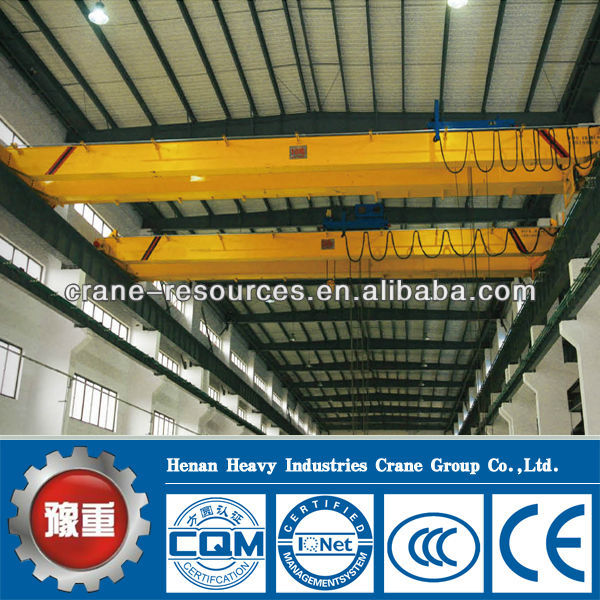

Low Clearance 5T, 10.5~31.5m Span,16m Lifting Height CE European Style Double Beam Over Head Crane, Customized Crane Available

| Feature:Other | Condition:New | Rated Loading Capacity:5 T | Max. Lifting Load:5 T |

| Max. Lifting Height:16 m | Span:10.5~31.5 m | Place of Origin:Henan China (Mainland) | Model Number:A5 |

| Certification:CE | After-sales Service Provided:Engineers available to service machinery overseas | Girder:European Style Optimal Design | Girder Plate QC:Untrasonic Checking |

| Whole Beam Shot Blasting:Sa2.5 | Beam Coating:Zinc-rich Epoxy Painting | Coting Life Span:Above 10 years | Hoisting:Original Germany Technology |

| Hoisting Design:Moudular Design | Trolley Travel:Stepless Speed Regulation | Over Loading And Temperature Protection:Available | Cable Wire Strength:2160 KN/mm2 |

CE European Style Over Head Crane 1~200 T, Customized Crane Available

An overhead crane, also known as a bridge crane, is a type of crane where the hook-and-line mechanism runs along a horizontal beam that itself runs along two widely separated rails. Often it is in a long factory building and runs along rails along the building's two long walls. It is similar to a gantry crane. Overhead cranes typically consist of either a single beam or a double beam construction. These can be built using typical steel beams or a more complex box girder type. Pictured on the right is a single bridge box girder crane with the hoist and system operated with a control pendant. Double girder bridge are more typical when needing heavier capacity systems from 10 tons and above. The advantage of the box girder type configuration results in a system that has a lower deadweight yet a stronger overall system integrity. Also included would be a hoist to lift the items, the bridge, which spans the area covered by the crane, and a trolley to move along the bridge.

In many instances the cost of a bridge crane can be largely offset with savings from not renting mobile cranes in the construction of a facility that uses a lot of heavy process equipment.

We are specialied in

♦Europea Style Double Beam Crane(Low Clearance):

♦Our Superior Technology Strength for teh European Style Crane

A:Lighter Dead Weight

With MARKMAN software’s optimal design and sophisticated technology, the crane’s dead weight is far lighter than the conventional cranes for the structures from blocks, end beams to g0 grinders are most reasonable. Thus it applies little wheel pressure to the rails, requiring less for workshop space, has a winder scope ,has a winder scope of application and saves construction cost of workshops.

B: Smaller Occupied Space

The crane can make effective use of workshop’s space. The hook has a little ultimate distance to the walls at both sides,and lower clearance height.Thus the existing workshops may give wider effective working space and the allocation plan will be more flexiable. Additionally.new workshops can be smaller and much functional.

C: Higher Working Performance

With variable frequency technology, the crane can run steadily, minimizing the swing of the load and thus ensuring more fast and accurate load positioning. Besides, it can also reduce the frication and mechanical stress between the crane and the workshops structure.

As the cable drum is larger in diameter and shorter in length, the hook has a shortest horizontal travelling distance in falling. As a result, the load positioning is more accurate, that is lifting 1 meter only need the hook to move horizontally 5 mm. For the working conditions, where horizontal travel is not allowed, a crane with double-rope lifting equipment can be used.

D: Easier Operation

The crane adopts many hanging controllers suitable for ergonomic design to control all the functions, including auxiliary lifting tools for material conveying such as electromagnet. The LCD handing button box can make interactive communication with ControlPro safty and performance control system, so as to continuously display important information in lifting loads.

It can also be optionally equipped with wireless remote control systems.The radio control, hand-held type or joystick type, provides the best control solutions for the application of lifting equipment in serve and complex environment.

E: Safe And Reliable

European-style cranes have more than ten protective measures such as over-temperature protection, overload protection and phase sequence protection, ensuring the cranes of safe operation.

The lifting equipment has a drum whose diameter is more than twice as large as the conventional one, while the deflection angle of cable wire is little. Such structure can reduce the tension and wear applied to the cable wire.

The high-performance lifting motor can both provide greater horsepower and show excellent cooling characteristics and continuous energy. Large capacity lifting equipment is designed with two lifting motors.

The electric block has an outstanding power transmission and braking system, which ,with dustproof design, can automatically make adjustment. Two brakes may be furnished as specially required.

The crane is equipped with the state-of-art electric control system0ControlPro to make measuring, computation and monitoring for the crane’s performance, safty and operaton so as to convey material in a much easier and safer manner.

F: Lower Operation and Maintenance Cost

The new European-style crane of us adopts the concept of green design, realizing the lower overall power consumption and electricity consumption.

The new European-style crane of us is reliable in quality and boasts a lower fault rate in correct application, minimizing the loss due to fault shutdown and saving maintenance cost as well.

12 Reasons For Your Choosing Our Crane:

Reason 1: Grinder

♦ European-style optimal design

♦ All the plates are detected by ultrasonic thickness gauge, maintaining a strict standard for the thickness.

♦ Full numerical control blanking ensures smooth camber curves.

♦ Shaped grid boxing technology ensures small deformation.

♦ Automatic welding, non-destructive detection.

♦ Shot blasting of the whole beam, Level Sa2.5,can eliminate welding stress.

♦ Zinc-rich epoxy paint ensures more than 10-year life span.

♦ Girder color: RAL 1028

Reason 2: Hoisting Mechanism:

♦Hanging hoisting system at the flexible side

♦Modular design ensures easy installation and maintenance

♦Variable frequency stepless speed regulation for trolley travel

♦Germany technology

Reason3: Lifting Motor, Reduction Gearbox

♦Squirrel-cage, double speed ( variable frequency) lifting motor, maintenance-free.

♦ Level of preotection:IP55

♦ Load duration rate 60% ED

♦ Built-in thermal resistor over-temperature protection, optical air-cooling

♦ Compact side-suspended gearbox

♦ Hard tooth surface, good reliability and long lifetime

♦ Muted design

♦ Semi-grease lubrication ensures good sealing and no oil leak

Reason 4: Brake

♦ Electromagnetic disk brake

♦ Compact, normally-closed

♦ The brake moment is large, up to 300%

♦ Automatic compensation for brake clearance, maintenance-free

♦ Auto alarm of brake block thickness

♦ Good sealing,dustproof

♦ There is no asbestos friction sheet, ensuring long lifetime and environmental protection

Reason 5: Limit Switch

♦Rotary cam limit switch meshes with the speed reducer, accurately computing the lifting height

♦Four-point type and programmable, adjustable to height control

♦Lifting decelerates the limit to reduce impact

♦The extreme limit can effectively prevent hook over-hoisting

♦Accurate phase sequency control

Reason 6: Drum And Cable Wire:

♦ Super-large diameter

♦ Welded drum, light dead weight

♦ The diameter ratio of drum and cable wire is up to 46 (domestic conventional design is 27)

♦ The curvature of cable wire is large, prolonging the lifetime

♦ The load positioning is accurate and deflection is little

♦ High strength galvanized cable wire boasts a breaking force of 2160 KN/mm2

♦ The cable wire needs wire needs no rust-preventative oil, and is maintenance free an clean

♦ Ductile cast iron rope guide causes less wear to the cable wire so that it has long life

Reason 7: Three-in -one Motor:

♦ Squirrel-cage variable-frequency motor

♦ Level of preotection:IP55 Load duration 60% ED

♦ It runs steadily, lowering the shaking of load in starting and speed changing

♦ Hard tooth surface, and muted design

♦ Disc brake

Reason 8: Safety Control Unit

♦ It can compute the remaining safe working

♦ It accumulates the hoisting working hours, over-loading times and number of starts

♦ Hoisting motor over-temperature protection and alarm

♦ Over-load protection and alarm

♦ Brake block thickness alarm

Reason 9: Safe Sliding Line:

♦Anticorrosive, insulated enclosed, compact composite safe sliding line

♦High conductivity, low pressure drop

♦Light dead weight, easy installation, maintenance free

♦Range of service temperature:-30°C ~ +60°C

♦The current collector slides at a high speed, ensuring continuous supply of power

Reason 10: Electrical Control Cabinet:

♦The control cabinets whose surface is furnished with antiseptic treatment are rationally distributed and easy for

maintenance

♦ Level of protection: IP55

♦ Ambient temperature:<45 Celsius degree , humidity: <90%

♦ Main power supply :three-phase four wire,380V (±10%),50Hz (±5%)

♦ All wires are equipped with color, number or wire size mark to make easy identification

♦ All externally connected cables have wire size mark

♦ Fixed cables are laid in raceways or protective tubes (galvanized steel pipe)

Reason 11: Trolley Cable-towing System

♦ Composed of flexible flat cable, cable-towing trolley and C-type rail

♦ Flat cables have good elasticity

♦ Air outlet-type connection is easy for alignment and connection

♦ Maintenance free, and long life

Reason 12: Trolley Track:

♦Hot-rolled flat steel, good forming

♦ Light dead weight

♦ High contact rate to wheel tread

♦ Low gauge torlance,trolley

| Packaging Detail:Standard Exporting Package |

| Delivery Detail:15 Days |