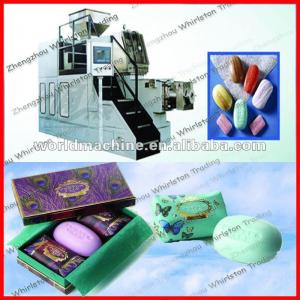

LN030002 large model toilet soap making machine

| Product Type:Soap | Place of Origin:Henan China (Mainland) | Brand Name:WHIR | Model Number:WIR-500 |

| After-sales Service Provided:Engineers available to service machinery overseas | Machine Type:extruder machine | motor:Energy saving | quality:good and durable |

| production line:finishing line from soap noodle | material:stainless steel |

large model toilet soap making machine

introduction:

1.This machine has two stages, driven by independent transmission system. The first plodder is acting as a simplex refining to make soap pellets in the vacuum condition. In the final plodder, the soap is pressed and extruded out in billets through the orifice to feed the downstream cutter or stamper. All gears are precisely manufactured. The screws are made of high quality stainless steel or aluminum alloy, which are strong corrosionresistant and durable for long production.

2. All other parts which are in contact with the soap are made of high quality stainless steel. The capacity can be adjusted by the VFD or the electromagnetic speed regulation motor.

Main Machines involved for making laundry soap

1. Mixer

Used for mixing soap noodles.

2. Three Roller Mill

Used for grinding soap noodles into thin sheets.

3. Plodder (Extruder) Machine

Used for molding the sheets into long strip soap of required shape.

4. Cutting Machine

Used for cutting the long strip soap into soap bar that is desired size .

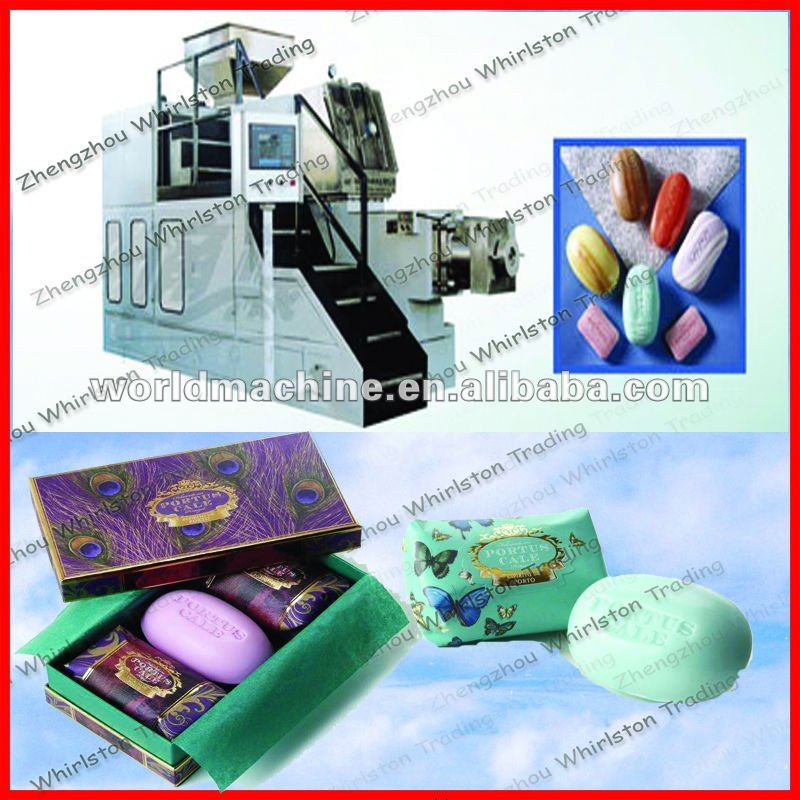

5. Packing machine:

individually packed in plastic wrapper,or loose-packed (such as 5bars) in one shrinkage bag.

specifications:

| Type | WHIR-500 | WHIR-800 |

| Production Capacity(kg/h) | 500-600 | 800-1000 |

| Screw Diameter(mm) | 200 | 300 |

| Screw Speed(rpm) | 15/18 | 12/16 |

| Power(kw) | 5.5/11 | 11/18.5 |

| Dimensions(mm) | 2810x900x1920 | 3758x1104x2270 |

| Weight (kg) | 1600 | 5550 |

| Packaging Detail:wooden package |

| Delivery Detail:within 7 days |