LLW Horizontal Axis Solid Discharge Screen Food Centrifuges

| Place of Origin:Jiangsu China (Mainland) | Brand Name:Hengrui | Model Number:LLW350 | choice scale of speed difference:10-40 r/min |

| discharging methed:mixedly or separately discharged | Rotation rate of basket(r/min):3000 | used in:chemical,salt,alkali,environment protection and other trades | Relative Centrifugal force:1770 |

| Productivity m3/h:2-8 | Overall Dimensions(l*w*h)(mm):1400*1250*1150 | Power of motor(kw):11 | Machine Type:Centrifuge |

| Product Type:LLW350 Horizontal Axis Solid Discharge Screen Centrifuges |

LLW Horizontal Axis Solid Discharge Screen Food Centrifuges

Technical Parameters

models | LLW350 | LLW450 | LLW520 | |

rotor drum | inlet amount | 10 | 20 | 25 |

| Rotation rate of basket(r/min) | 2800 | 2300 | 2000 | |

| Relative Centrifugal force | 1500 | 1300 | 1200 | |

Power of motor(kw) | 11 | 22 | 30 | |

Weight(kg) | 900 | 1200 | 1800 | |

Overall Dimensions(l*w*h)(mm) | 1150*1500*970 | 1150*1500*1150 | 1480*1920*1470 | |

LLW series scroll discharge screen centrifuge is the one with low energy consumption, stable performance and good separating effectiveness. It is widely applied to chemical, foodstuffs, salts, mining and pharmacy industries. The separation processing from feeding to dewatering, cleaning and discharging is continuous with high processing efficiency and degree of automation(We have accumulated successful experience for separation of tens of kinds of material. In choosing pattern, please communicate with our technicians so as to get more detailed documents). It is the advanced separation equipment. | ||||

1 double-frequency control, to support customers improve production efficiency.

2 the use of thin oil lubrication system to protect the mechanical drive failure-free operation.

3 set the automatic cooling system.

4 set the automatic temperature control system.

5 and all material contact parts made of high quality stainless steel.

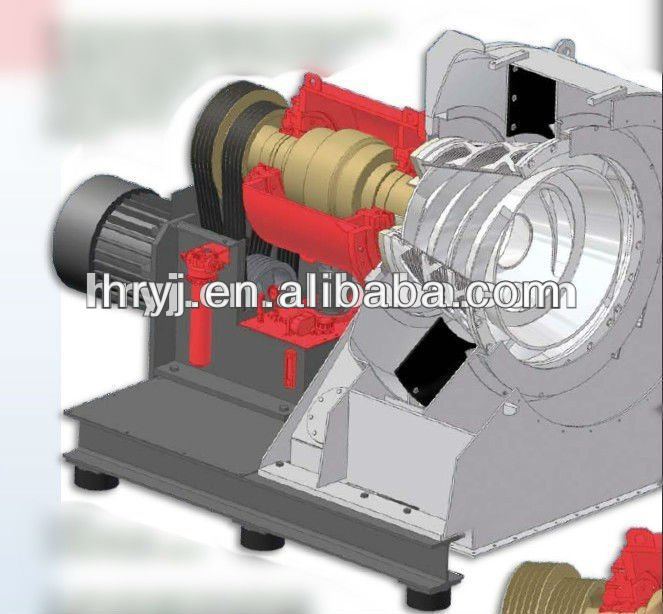

Principles of product structure

Motor drives the drum and the feeding installation concentric spiral, to a certain degree of differential rotation with the speed, the material from the feed tube into a continuous, uniform distribution to the Bottom of the filter drum wall, under the centrifugal force, liquid materials through the filter and drum filter vent drum wall, the liquid discharge port from the plane.

| Packaging Detail:Standard with wooden pallet and poly film case |

| Delivery Detail:60 days after order |