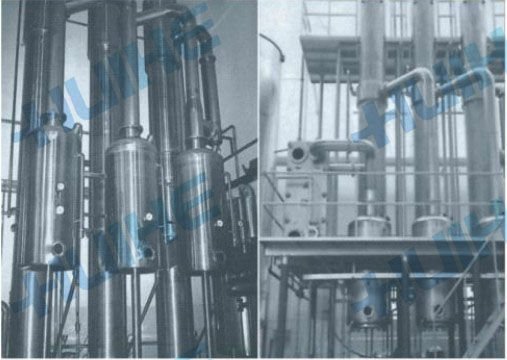

LJN Three effect falling-film continuous feeding concentrator

1.Continuous feeding and discharge, 2.Large concentration density, 3.Convenient to employmentof advanced control mode - details see: https://www.machineto.com/ljn-three-effect-falling-film-continuous-feeding-concentrator-10022246

| Processing:Concentrator | Place of Origin:Zhejiang China (Mainland) | Brand Name:HH | Model Number:LJN |

| Processing Types:Liquid | Material:Stainless Steel |

Features

- Continuous feeding and discharge, stable and convenient operation. The only operation package of setting of different parameters at the beginning of feeding, assurance of reliable and stable feeding supply and easy regulation can certainly produce continuous, stable and efficient concentration, get qualified density and simultaneously recover solvent.

- Large concentration density(1.25-1.28),high heat efficiency and effective energy-saving fruit. To this system, we used optimum to leave a vaporization heat transmission coefficient of 3400-3800 w(m*m.K), which is very benefit to concentration of Chinese extraction liquid. The cause for it is that the material flows quickly with the form of film inside the acceleration pipe, and simultaneously, the temperature difference for heat is somewhat small, (just 8-10°C). The material can form quickly. Flashing, the medicine liquid stays and be heated for short time, the adaptation scope of material viscidity is wide,(50-500cp), the even heating excludes crystallization, and then to deposition and even coke. So it features little destroy to effective element, full utilization of heat energy and fruitful energy-saving.

- Convenient to employment of advanced control mode. The temperature index for series LJN concentration flow is mainly subject to the temperature of each of effect. Each of parameter keeps stable during system performance, which benefits the utilization of advanced control unit featuring (PLC and man-machine interface control) and leaves the lower cost of control equipment, makes the production of Chinese drug by automatic control great convenience.

- Advanced and reasonable structure. We used optimum design scheme. Advanced distribution device is responsible for liquid is attribution during feeding and flow inside the pipe to make the material able to enter heating tube evenly. Simultaneously, the heating tube, made by qualified and imported inner-wall mirror tube, can reduce the flow resistance to the material inside the tube, increase the flow speed, and prevent crystallization and deposition. To lift concentration efficiency, the advanced mist collector can eliminate mist. The separation efficiency can be of 96%-99%, with low resistance.

| Packaging Detail:export standard wooden package |

| Delivery Detail:in 15 days |