Lifting machine jib crane manufacturer

| Feature:Jib Crane | Condition:New | Application:widely | Rated Loading Capacity:5t |

| Rated Lifting Moment:50KN | Max. Lifting Load:5t | Max. Lifting Height:15m | Span:up to 12m |

| Place of Origin:Henan China (Mainland) | Brand Name:Tengsheng brand | Model Number:BZ/BZD model | Certification:ISO certificates |

| Warranty:12 months | After-sales Service Provided:Engineers available to service machinery overseas | working duty:M3-M5 | Electrical system:Schneider/CHNT |

| Painting color:According to your demand | Double limit switch:Included | Current overload protection function:Included | Voltage lower protector:Included |

| Certificate:ISO/SGS/CE | Paint:As per client's requirement | Control mode:Pendant/wireless remote control | Key word:Lifting machine jib crane manufacturer |

♥Technical parameter for Lifting machine jib crane manufacturer | |

| Model | Lifting machine jib crane manufacturer |

| Lifting height | 7-30m |

| Span length | 6-32m |

| Lifting mechanism | CD/MD electric hoist |

| Motors | Nanjing Zongchang(Number 1 in China) |

| Power supply | 380V/50HZ or based on your requirement |

| Safety feature | Limit switch; Overload stop device for hoisting; Long bearing buffer for crane traveling; Power failure back-up |

| Package | Electrical parts are packed by strong plywood crate,rest are packed by polyethylene woven bag. |

| Delivery time | EXW 30 days after receiving your advanced payment |

| Shipping port | Qingdao,Tianjin port |

| Electrical equipment | 1.This mechanism consists of electric control box,button switch, position-limiter and connecting wire elt. 2.The operation voltage is usually 380V/36V,so please notify your special required according to the marked direction on the switch and control the hoist through the on-and-off of the relays in the control box. 3.The circuit diagrams in this manual should be used together with attached motor and electrical routes. |

| Introduction | It is mainly composed of bridge,running gear of crane,electric hoist and electric device,etc. |

| Working environment | 1.This product is widely used in plants,warehouses,material stocks to lift goods or materials. 2.It is prohibited to use the equipment in the combustible. 3.Its proper working temperature is -25°C to +40°C |

| After-sale service | 1.The whole machines would be guaranteed for one year. 2.All the crane are equipped with overload protection device. 3.Emergency stop system and so on. |

| Working grade | A3-A5 according to the use grad and load-up condition. |

| Technical parameters: | 1.Crane material:Q235,Q345B/Q345D 2.Wheels are vacuum casting by ourselves,intermediate frequency quenching. 3.Wheels,wire rope,drum,gears,coupling are manufactured by our CNC machines. 4.Nanjing special or Nanjing Brand motor,top quality in China. 5.Eletrical equipments:Siemens or Schneider brand. 6.Control method:Cabin control,wireless remote control or pendant control,You can choose two of them. |

| Ordering Notice | 1.Capacity:max lifting load. 2.Lifting height:___m(hook center to ground) 3.Span length:___m(rail center to rail center) 4.Traveling distance? 5.Power supply:380V/50HZ is ok? 6.Would be better if you can send us workshop drawing. |

Main component of Lifting machine jib crane manufacturer

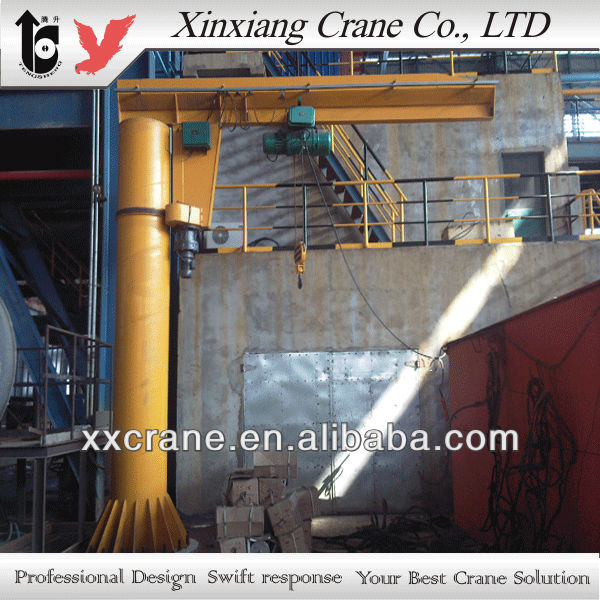

Plant view

Base foundation before install Lifting machine jib crane manufacturer

Professioanl package of Lifting machine jib crane manufacturer

♥ Spare part for Lifting machine jib crane manufacturer | |

| Motor: | Hoist Motor is a taper type rotor motor with braking, it is made by Nanjing special motor factory, it is of the best quality motors, it has bigger torque, so it can be adapted to moving frequently, the Maximum torque is 2.4-3 times than the rated torque. |

| Gear Box: | Hoist Gear Box has specially treated gears for high wear resistance. Each Geared Shaft assembly is supported on ball or roller bearings, to ensure smooth, low-friction operation. |

| Wire Rope: | Hoisting ropes comply with the exporting standards. The leading rope taken by the Drum does not slip sideways when slack. The factor of safety, on the nominal breaking strength of the rope is six. |

| Rope Drum: | Grooved Drum, seamless pipe of adequate length to be wounded in one layer and to provide proper support for the rope to minimize abrasive wear is provided. Drum Shaft resolves on Ball Bearings for ensuring smooth running. |

| Electric apparatus controlling system: | Model CD1 and MD1 is composed of the contactor box, controlling switch, cut-off limiter, the working voltage of controlling switch is 380V,36V or 24V (safety voltage). |

| Rope Guide: | Rope Guide is in two halves, ensuring easy accessibility. It encircles the Drum completely so that the rope may not uncoil even when the Hoist is in unloaded condition. The rope guides of our company is thickened and dilated, so that it is not easy to be damaged. |

| Hook: | The Hook Block is tested to 150 % of full load before assembly. The rope sheaves are fully guarded with protective steel casting. All sheaves rotate on ball bearing the pulley is thicken and dilated than domestic common pulley. |

| Packaging Detail:Packed by high quality plywood crate |

| Delivery Detail:within 30 years after receiving deposit |