Lathe Bed for Machine Tool - Heavy Casting/Grey Iron

| Type:Table | Material:Spheroidal Graphite, Gray iron etc. (HT200-300, QT400-500 etc.) | Brand:Zhongbo Heavy Industry | Model:ZBZG2013002 |

| Product Category:Machine Tool Castings And Accessories | Name:Lathe Bed for Machine Tools | Specification:Standard and Heterogeneous Type | Casting Equipment:Cupola Furnace/ Industrial Electric Furnace |

| Surface Treatment:Painting, Heat Treatment, Finish Plane etc. | Casting Technique:Resin Sand Casting etc. | Fine Finishing:Complete machining:CNC, Lathe,Milling machine, drilling etc. | Quality Assurance:Physical and Chemical Inspection Report,Metallographic Examination.... |

| Packing:Export Packing:Wooden Cases, Steel Cases |

Product Detailed Description:

| Product Category | Machine Tool Castings And Accessories, Lathe Bed |

| Product Standard | Machine Tool Castings Standard: GB9434-88; Quality tolerances:GB/T11351-89; Dimensional tolerances:GB6414-1999; Cast Iron Surface Plate Standard: JB/T7974-1999 |

| Specification | Standard and Heterogeneous Type |

| Casting Equipment | Cupola Furnace/Industrial Electric Furnace |

| Casting Technique | Resin Sand Casting etc. |

| Material | Spheroidal Graphite, Gray ironetc. (HT200-300, QT400-500 etc.) |

| Weight | 1000kgs-50000kgs |

| Surface Treatment | Painting, Heat Treatment, Finish Plane etc. |

| Fine Finishing | Complete machining such as Machining center, CNC, Lathe, Milling machine, drilling etc. |

| Quality Assurance | Physical and ChemicalInspection Report, Metallographic Examination, DIM Inspection Report, and Customer Requirements Reports. (Third Party inspection available upon customers requirements) |

| Packing | Export Packing:Wooden Cases, Steel Cases |

| Size and design | As per the customer's drawings and requirements (we can offer the new drawings to the customer) |

We will strictly observe the processing requirement as stipulate in the drawings and contract. We can accept the payment:T/T, L/Cetc. | |

Machine tool castingsalso be calledheavy castings,the standard is GB9439-88, the material is HT200-300, it’s divided into sand mold casting and special casting. The machine tool castings’ production is that the metal mixture is heated to melt, so that it has the fluidity, and then poured into the mold cavity with a certain shape, under gravity or external force (Pressure, centrifugal force, electromagnetic force etc.) the mold cavity is full filled by the liquid, form the machine tool casting (parts) after the liquid is cooled and solidified.

Our company can design drawings and produce according to the customer requirements.

We can design and meet actual application drawings according to customers’ requirements.

Thelathe bedshould to be the annealing treatment which can reduce the hardness of metals and improve the plasticity and eliminate the residual stress to prevent the deformation and crack.

---------------------------------------------------------------------------------------------------------------------------------------

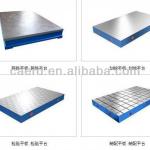

Cangzhou Zhongbo Heavy Industry Manchinery &Equipment Co.Ltd----a reliable and professional manufacture offer qualitative products like:Non Sparking Safety Tools, Special Tools, Non Magnetic Tools, Electrostatic Prevention Equipments, Non Sparking Safety Toolboxes, Measuring Instruments, Cast Alloy Iron, Heavy Castings, Lathe bed castings, Casting iron surface plates and so on.

| Packaging Detail:Exporting package or as clients' requirements. |

| Delivery Detail:According to the customer's purchase quantity |