Latest Technology Dry Mortar Powder Production Line From Alibaba China With Competitive Price

| Condition:New | Application:manufacture dry mortar | Production Capacity:12-260t/h | Place of Origin:Shandong China (Mainland) |

| Brand Name:WFLJ | Model Number:WFLJ1000 | Voltage:380V | Power(W):50-600KW |

| Dimension(L*W*H):According to your requirement | Weight:about 10t | Features:environmental and low cost | Certification:ISO 9001 |

| Warranty:one year | After-sales Service Provided:Engineers available to service machinery overseas | Block-type:dry mortar production line |

dry mortar mixer production line

1.high efficiency

2.low consumption and voice

3.warranty:12 month

4.100% inspection before shipment and ISO 9001 certificate

Model | Supporting host | Power (kw) | Capacity (t/h) | floor space (m2) |

WFLJ1000 | WZ-1.0 | 50 | 12 | 450 |

WFLJ2000 | WZ-2.0 | 80 | 21 | 700 |

WFLJ4000 | WZ-4.0 | 200 | 43 | 900 |

WFLJ6000 | WZ-6.0 | 280 | 85 | 1300 |

WFLJ8000 | WZ-8.0 | 360 | 125 | 1800 |

WFLJ10000 | WZ-10.0 | 450 | 200 | 2200 |

WFLJ12000 | WZ-12.0 | 600 | 260 | 3000 |

| MODE | CAPACITY | AREA | REMARK | |

| Simple | 1~15t/h | 40 m2 | Manual batching and packing | |

| Basic | 5~15t/h | 40~60m2 | Manual batching, automatic packing | |

| Semi-automatic Serial | 5~15t/h | 40~80m2 | Automatic batching of coarse material, manual batching of additive, automatic packing | |

| Semi-automatic Tower | 5~50t/h | 40~100m2 | Automatic batching of coarse material, manual batching of additive, automatic packing | |

| Fully Automatic Tower | 5~100t/h | 60~500m2 | Automatic batching of raw material and packing |

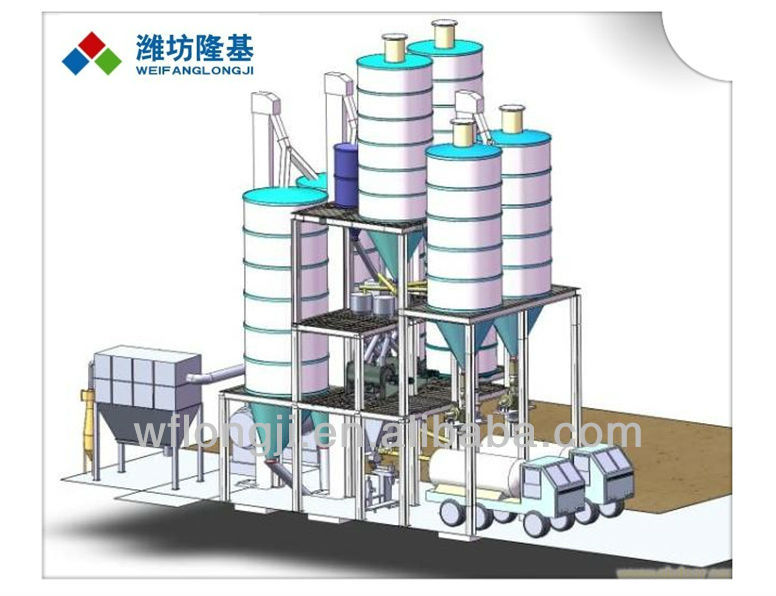

This line mainly consists of the following parts:

material store silo , spiral conveyor, dosing scale, bucket elevator, pre-mixing silo, small bin, mixer, end product silo, packing machine, dust collector, air compressor, air-phase balance system, second mixer, steel platform and control system.

Manufacturing Process:

Raw materials of large propotion are conveyed to dosing scale by screw conveyor and small materials are conveyed by small bin. All the materials are mixed by mixer, then measured and packed automatically by packing machine, lastly conveyed to finished product stortage area by conveyor.

Advantage for Block-type mortar production line:

Compared with simple-type production line, this line can not only feed large materials (cement/coal ash) automatically, but also install automatic alarm device on the storage tank.

Features for Block-type mortar production line:

It has the following features: feed automatically, dosing automatically, packing automatically, low cost, reasonable process, and recognized by national construction hall.

Cost for Block-type mortar production line:

The investment is about 70000-100000USDand output is 5-15 tons each hour.

Usage for Block-type mortar production line:

This line is the best choice for companies in certain scale and market, applied to manufacture exterior insulation mortar, self leveling mortar, mortar repair, waterproof mortar, HAZG, tile adhesive, joint mixture, etc. in large and medium enterprises.

Payment Terms and Conditions of dry mortar mixer

1. Quotation (EXW price with tax) is valid for one month .

2. Delivery time:30 days after receipt of your deposit.

3. Payment terms:50% T/T in advance, the left is paid (by T/T) before leaving loading port. If open L/C, there is 2% of L/C amount for bank charge.

4. Package: nude packing, with 20HC/40HC.

5. MOQ: one set

Welcome your kind enquiry by sales (at)wflj(dot)com

Photos:

| Packaging Detail:Seaworthy package |

| Delivery Detail:30 days |