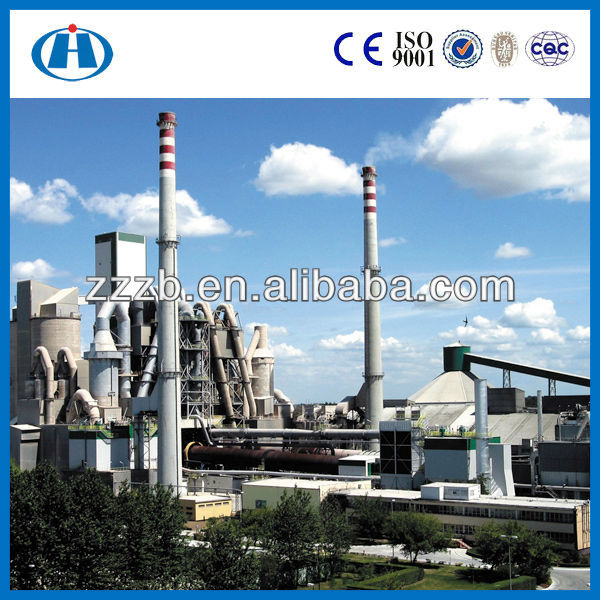

latest high quality cement plant with ISO CE approved

| Condition:New | Place of Origin:Henan China (Mainland) | Brand Name:Hongji | Model Number:Various and according customer's request |

| Dimension(L*W*H):depends on the model | Certification:ISO CE SGS | Warranty:one year | After-sales Service Provided:Engineers available to service machinery overseas |

| Color:Different color as client required | Grinding way:dry or wet | Service period:whole using life | Capacity(t/d):100-5000 |

| Maintain:easy and cheap | Structure&cost:simple and low | Installation:Under our engineer's guide | Spare parts:Supply by us |

| Logo:OEM | Product name:cement plant |

latest high quality cement plant with ISO CE approved

1. Company Introduction:

Our factory is a manufacturer and exporter of mining machinery in China.

Our main products aregrinding mill, briquetting machine,sand making production line, stone production line, magnetic separating production line, Flotation separating production line, cement production line, crusher, dryer, rotary dryer, rotary kiln, coal gasifier, conveyor, ball milland so on.

All of them are ISO9001:2008 confirmed.

2.Description of cement:

Main technical characteristics of cement plant

1.This production line adopts advanced technology and equipment in 1990s to raise technical level and to ensure design indexes. New five-stage cyclone pre-heater system, high efficiency air girder grate cooler, multi-passage pulverized coal burner, Davison heat temperature fan, Luqi BS930 electrical dust collector, as well as chain-board elevator, chain conveyor adopted in this production line can ensure that the technology is advanced compared to other production lines with the same scale.

2.If it has not bad influences on completeness,continuity and reliability, process procedures will be simplified to enhance production management, reduce troubles and lower investment.

3.Top of silos are without covers, heat temperature fan and dust collectors are open arranged and glass fiber rainproof covers instead of roofs will be set for belt conveyor passages. There will be no building for bucket elevator.

If it has not bad influences on normal production, by properly reducing storage periods for all raw materials, semi-product and finished product and adopting shed to store those materials and products, civil engineering costs will be greatly reduced.

Frame for pre-heater at kiln inlet will adopt steel structure to save investment, accelerate erection speed and beautify building.

4.Measures have been taken to save energy and reduce consumption. using chain-board elevator and air slides, reliability of the system is enhanced and conveying energy consumption is decreased.

5.All necessary parts will adopt measuring equipment to guarantee scientific management. For example, there are measuring equipment at those parts such as raw meal blending, raw materials entering into plant, raw meal feeding to kiln, pulverized coal feeding to kiln, clinker outgoing kiln and clinker outgoing silos.

6.Effective measures have been taken to guarantee strict environment protection standards. Different efficient dust collectors are set at all dust producing points according to different characteristics of waste gas.

Cement production line consists of raw material grinding, blending, pre-calcining, clinker burning and cement grinding.

The equipments we use in this whole production line are vibrating feeder, jaw crusher, impact crusher, cement ball mill, lifer, preheating system, cement rotary kiln, rotary dryer and packing machine and so on. All the necessary equipments in this line can be provided by our factory. We have cement production line experts to design specific solutions for your preference.

3.Cement plant line process:

1) Crushing

In this process, most of raw material should be crushed, such as limestone, clay, iron ore and coal. Limestone is the largest amount of raw materials in cement production line, so it is very important in cement production line.

2) Pro-homogenization

Raw material pro-homogenization is making the raw material yard with storage and pro-homogenization function by applying scientific stacker technology.

3) Raw material preparation

In cement production process, to produce 1 ton of Portland cement must grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials, gypsum). According to statistics, grinding operations in the dry-process cement production line need to consume power accounts for about 60% of the whole plant power, of which 30% of raw material grinding, more than about 3% of coal mill, cement grinding about 40%. Therefore, a reasonable choice grinding equipment and processes, optimizing the process parameters, proper operation and controlling operation system is of great significance.

4) Raw material pro-homogenization

The system of raw material pro-homogenization plays a raw meal of raw ingredients stability of pit entry last gatekeepers.

5) Preheat & decomposition

Raw material preheating and decomposition is completed by preheater, which can improve the kiln system productivity and reduce heat consumption of clinker Purposes.

6) The burning of cement clinker

Raw material is carried out into the rotary kiln clinker for completion after preheating in the preheater and pre-decomposition.

7) Cement grinding

Cement grinding is the last process of cement production line, also the most power consuming process. Its main function is to grind the cement clinker (and gelling agent, performance tuning materials, etc.) into the appropriate size and a certain particle size distribution, which is for increasing the size of its hydration, accelerating the hydration rate and meeting the coagulation, hardening requirements.

Simplified process of cement production:

Raw materials extraction (mining) → crushing→ raw materials storage and pre-homogenization (ball mill) →raw material homogenization and storage, calcinations (raw material enter into rotary kiln after pre-heater in cyclone tube, calcinated to clinker) → cement grinding (mix other chemical material according to cement quality to grind) → cement storage and transportation

4. Export country of cement plant:

Russia,India, Vietnam, Kazakhstan, Mongolia, Pakistan, Iran, Ecuador, middle east, Oceania, Europe , America and other countries and areas.

| Packaging Detail:export standard or nude packing,spare parts in wooden case or according to customer's demand |

| Delivery Detail:in 25-30 working days after confirm the order |