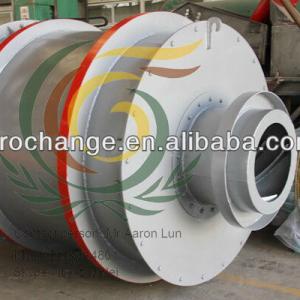

Large capacity Silica Sand Drum Dryer with widely use to different material

| Condition:New | Type:Drum Drying Equipment | Place of Origin:Henan China (Mainland) | Brand Name:bochuang |

| Model Number:BCS | Voltage:380 V others | Power(W):2.2- 22 kw | Dimension(L*W*H):different model different |

| Weight:3- 45 ton | Certification:CE, ISO9001:2000 | Warranty:two years | After-sales Service Provided:Engineers available to service machinery overseas |

| Color:According To Client Needs | Material:Q235B carbon steel plate or as client requirement | Installation:Supplier dispatch engineer | Drum Wall Thickness:8-22mm |

| Drying temperature:500-1000 degree celsius | Gradient:3-5 | Heating source:hot air stove,coal gasifier, gas an d oil burner or others | suitable Fuel:LPG,natural gas, diesel,coal, wood pellet, wood or others |

| fuel consumption:10-20 kg drying one ton |

silica sand drum dryer with widely use to different material silica sand drum dryer is one kind of large capacity rotary dryer. Because of our silica sand drum dryer easy operation, large elasticity of operation, strong adaptability, large capacity, widely used in building material, metallurgy, food, chemical, coal, medicine in the mining industry. This type quartz silica sand drum dryer generally adapted to granular materials,also can be used to drying the mixed material in the sticky paste material or material with high moisture content. This quartz silica sand drum dryer is very suitable to drying sand, such as ,silica sand,rive sand and other sand.silica sand drum dryer or sand rotary dryer has the advantage of large capacity, wide applicable range, small flow resistance, operation is allowed on the wide range and convenient operation, etc.

Working principle of quartz silica sand drum dryer:

The sand transport into the hopper by belt conveyor or bucket elevator,And then through the hopper feeder and loading pipes into the feed end .The feeding pipe slope is bigger than the natural inclination of sand , so that the sand can easy into the dryer.The rotary dryer is a horizontal line slightly tilted to the rotation of the cylinder.Feeding the material from higher part.

The sand from the higher end put into dryer, hot air can from the same direction or different direction into dryer. With the turning of dryer the material moving to the lower end,the slowly moving process is drying process, at the same time the wet sand full contact hot air and evaporation water, when the drying process finished used the belt conveyor transport out.

On the walls of silica sand drum dryer body is equipped with lifting plate,they are used to lifting the sand and dispersion to make the sand fully contact with hot air, improve the drying effect and promote the material advance.

Technical parameters of silica sand dryer:

| Model parameters | Φ2×4.5m | Φ2.2×5m | Φ2.5×6m | Φ2.7×6.5m | Φ3.0×6.5m | Φ3.2×7m | Φ3.6×8m | Φ4.2×8m |

| Outer cylinder diameter(m) | 2 | 2. 2 | 2. 5 | 2. 7 | 3. 0 | 3. 2 | 3. 6 | 4. 2 |

| Outer cylinder length (m) | 4.5 | 5 | 6 | 6.5 | 6.5 | 7 | 8 | 8 |

| Cylinder volume (m3) | 14.13 | 18.99 | 29.43 | 37.19 | 45.92 | 56.27 | 81.39 | 110.78 |

| Cylinder rotational speed(r/min) | 4-10 | 4-10 | 4-10 | 4-10 | 4-10 | 4-10 | 4-10 | 4-10 |

| Max intake air temperature(°C) | 700-750°C | 700-750°C | 700-750°C | 700-750°C | 700-750°C | 700-750°C | 700-750°C | 700-750°C |

| Capacity(t/h) | 13-18 | 15-23 | 20-28 | 24-33 | 35-40 | 40-60 | 55-75 | 70-120 |

| Motor power(kw) | 5.5×2 | 7.5×2 | 5.5×4 | 7.5×4 | 11×4 | 15×4 | 18.5×4 | 22×4 |

| Packaging Detail:Export standard container 20GP OR 40GP,40HQ,FR container,In bulk,the spare parts in wooden case. |

| Delivery Detail:15 -20 working days after received advance payment |