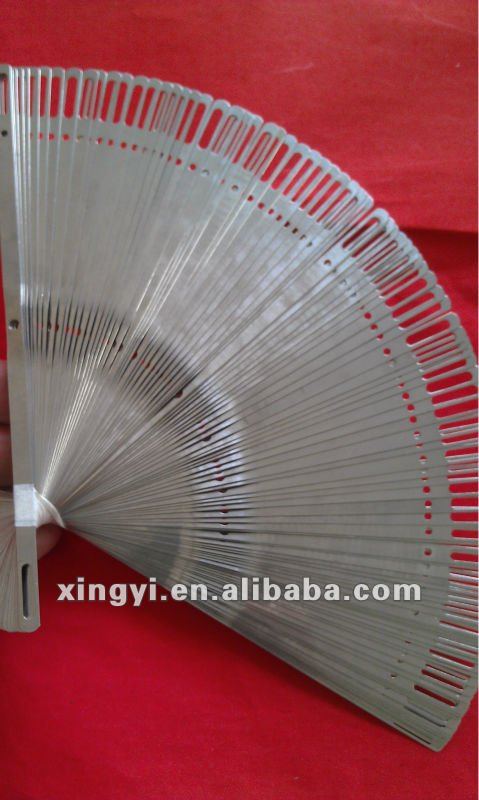

knitting wire heald

| Condition:New | Product Type:Belt | Type:Jacquard | Place of Origin:Jiangsu China (Mainland) |

| Brand Name:xingyi | Model Number:many types | Knitting Style:Flat | Knitting Method:Single |

| Computerized:Yes | material:stainless steel |

Wire heddle’s role in the weaving process

(1)Order effect According to the weaving fabric structure,warp are worn through the steel heddle’s eyes by hands or by automatic machine in the process requirements,and ordinal arranged.

(2)Opening role with the demand of weaving structure and through the lifted mention,when the warp are worn into wire heddle’s eyes,the wire heddle will move up and down regularly and make warp layered openings.

Wire heddle’s essential conditions for weaving technology

(1)It must have a certain flexibility, toughness, hardness and abrasion resistance

(2) It must be strictly straight

(3)Ensure accurate length, extremely accurate position, extreme small deviation.

(4)Ensure wire heddle’s eyes smooth,no burr and edges and corners , or it will broke warp.

(5)Higher water proofing property and High resistance to corrosion.So our use Stainless steel materials and Carbon steel materials.

Wire heddle’s features

compared with the traditional shuttle looms with wire heald, the new steel heald have following features

(1) simple structure, easy fabrication, be helpful for automation production.

(2) high strength, good flexibility and long service life.

(3) as the ears and eyes of steel heald have no twist, so it makes the warp opening much bigger, then it will improve the fabric’s quality.

(4)Because of sliced wire heddle,it is helpful to improve permutation density and weave dense and thin fabric.

1. Material:Our product adopts imported precision stainless steel belt as raw materials, good ductility and tensile function maximum prolong the service life of the product.

2. Mould :adopts the most advanced technology, ensure the smooth thread eyes,improve the quality of fabric.

3.Internationalimpact:function and quality are close to global textile machinery need.

4.Packaging:plastic bags and carton box inside,strong wooden box outside.Standard export package, custom suffocating free.

5.Our promise:once the product are sold,we will solve all problems within 24 hours.

| Packaging Detail:Packaging use union of inside and outside, inner packing with insulation membrane and hard carton packing and outer packing with strong wooden boxes, then it fully guarantee the product that won't bring customers inconvenience because of the improper operation in carriage process. |

| Delivery Detail:always delivery |