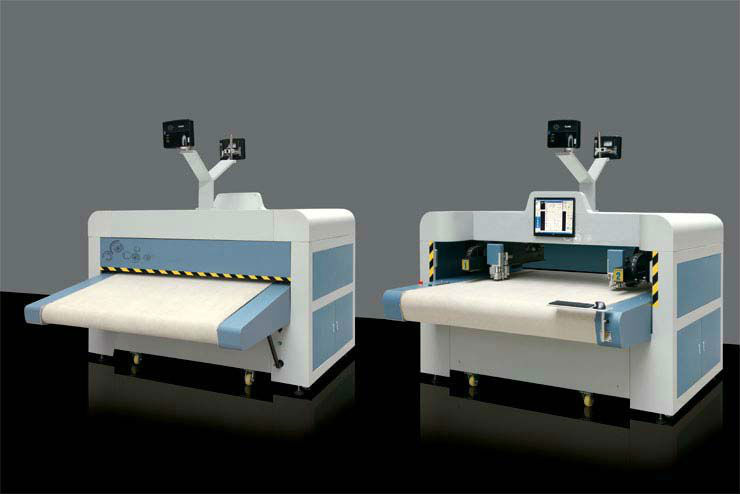

KENO-JD3212 CNC case/bag/leather cutting machinery

| Condition:New | Application:Leather cutting | Automatic Grade:Automatic | Production Capacity:100% |

| Place of Origin:Shanghai China (Mainland) | Brand Name:KENO | Model Number:KENO-JD3212 | Voltage:110V, 220V, 380V |

| Power(W):1.2KW | Dimension(L*W*H):2200X1350X1250mm | Weight:350KG | Features:Especial |

| Certification:CE | Warranty:One year warranty | Machine Type:Cloth Cutting Machine | Product:CNC cutting machine |

| Material Capabilities:Other |

CNC leather cutting machine

Brief Introduction:

This leather cutting system is a perfect combination of technique and technology. With this machine, you can conduct rapid nesting and efficient cutting operation, while saving time, manpower and material.

It works for a wide range of material, like genuine leather and many other kinds of flexible material. It is designed for sample cutting and small bulk production, specially providing a revolutionary cutting solution for footwear, case and bag, car and plane chair, furniture and apparel industries.

Features:

1. It adopts vibrating knife cutting technology, without having to forge die cutter, which saves the cost and the time on making die cutter, management and storage of die cutter during the process of production. It enables you to grow out of the traditional technique of manual cutting forever. And it completely broke through the bottleneck that the enterprises rely on skilled workers and enable the enterprise to take the lead to enter the non-die cutter digital processing era.

2. It features multi-purpose tool head, highly integrating multiple sets of processing tools. It can carry out interactive cutting, punching, drawing in a single period of running time, providing a workflow of production.

3.It can work out highly-challenged and complex patterns which the die cutter can not realize, there by extends the designing space of the designer dramatically, creating new-style patterns which can't be imitated by handwork and making your patterns more attractive, thus reach the level that the buzz word "creation can go as far ad your imagination can reach" communicates.

4. It can effectively identify flaws on leather by using the projector or camera to capture leather contour. And the user can adjust the cutting direction as he like in accordance with the texture of natural leather material, so as to increase the output of finished-products and reduce material loss; and eventually increase the effective rate of utilization of the materials.

5.The user can make timely correction to the patterns, which avoid investing the time on developing and making samples, and meet the fast-changing market demands through quick sample making and

error correction. You are supposed to achieve 2-3 days of time advantage over your competitors in terms of correction of the same kind of samples, thus helping you quickly seize the market opportunities.

6.All operations are computerized by using computer to simulate the operation process exactly, which rules out the interference from the factors of the workers' mood, knowledge, tiredness and other personal factors happened in traditional cutting, thus avoid hidden waste and increase the utilization rate of the materials.

Specifications:

Model: JD-3212, JD-2510, JD-1510, JD-1410, JD-1007

Cutting Speed: 80cm/s ~ 120cm /s

Cutting Thickness: 0.5mm ~ 6.0mm

Cutting Material: Natural Leather, Artificial Leather, Cardboard, Plastic Board,

Gray Board, Synthetic Materials, Underlay, White Board etc

Cutting Tool: Vibrating Knife Cutting Tool, Punching Tool, Drawing Tool

CuttingArea:(Length*Width)3200mm*1200mm,2500mm*1000mm,1500mm*1000mm,1400mm*1000mm,1000mm*700mm

Pen Type: Ordinary Signing Pen, Oil Pen, Ball Pen or Silver Pen

Pen Parameters:Pen, Half-cut and Full-cut can be set to 8 different types

Vacuum Plate:Vacuum based on Cells

Mechanical Resolution:0.07mm

Software Resolution:0.025mm \ 0.01mm \ 0.1mm optional

Transmission Interface:Standard Serial Interface, Parallel Port

Buffer Size: Once-and-for-all high-speed transmission

Command System: Language of HP-GL and GP-GL

Control Panel:LCD Display, Touch Button, Touch Screen

Host Power: AC220V,50HZ

Vacuum Power: 5.5KW/9KW, AC380V,50HZ

Hold-down Method: Vacuum Suction

| Packaging Detail:Wooden case |

| Delivery Detail:15 work days |