KCT-20B CNC wire forming machine&clips spring making machine

| Place of Origin:Guangdong China (Mainland) | Brand Name:KC | Model Number:KCT-20B | Condition:New |

| After-sales Service Provided:Engineers available to service machinery overseas | Wire size range:0.2-2.0 | Max outside diameter:50 | Max. Production rate:70pcs/min |

| Package:Vacuum packed |

Products description

1. 20B 3/4 Axis CNC Versatile Spring Rotating Forming Machine adopts TaiWan CNC control system and Japan Sanyo/Yaskawa Servo Motors to control the feeding system and Cam system synchronously.

2. It has total 4 axis, the Cam axis, Feeding axis, Quill Rotary axis, and the Spinner axis (optional).

This machine is suitable for making various Compression spring, Extension spring, Single (double) torsion spring, Tower shaped compression spring, Flat wire spring, and any kind wire forming.

Because this machine adopts the high accurate servo motor and CNC control system, it can produce the accurate size and complex spring if adds the Spinner axis,

Technical Parameter:

| Axis count | 3-4 |

| Wire size range | 0.2-2.0 |

| Max outside diameter | 50 |

| Max. feeding length | (Unlimited) |

| Max feeding speed | 110m/min |

| Max. Production rate | 70pcs/min |

| Wire Feeding servo motor | 2.7 KW |

| Cam Servo motor | 2.7KW |

| Quill servo motor | 1.0 KW |

| Dimension (L x W x H) | 1040 x 600 x 1575 |

| Weight | 1200 kg |

| Power | 3-380VAC 50HZ |

Standard accessory:

1.right coiling /bending tool mount

2.left coiling /bending tool mount

3.right arbor tool mount

4.left arbor tool mount

5.cut-off tool mount

6.pitch tool mount

7.cams

8.probe

9.air cylinder support

10.feed roller

11.coiling point

12.wire guide

13.tools box

Optionals:

1.rotary quill

2.servo spinner

3.cutting tools

4.wire pay-off

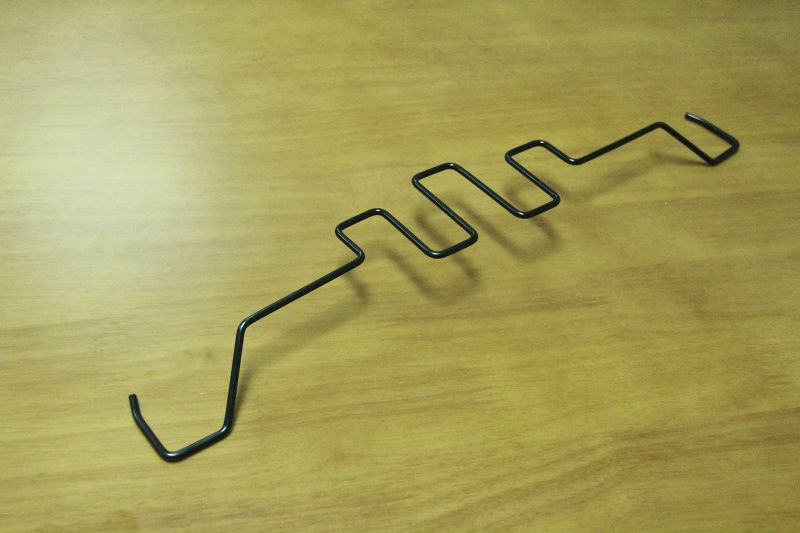

Spring sample:

Company view and proof of Qualification

Machine Packing

Our advantages:

1. The factory has about 15 years experience in this field, and the Founder Mr Liu has about 32 years experience for manufacturing the Spring Machine who witnessed the Spring Industry development in China.

2. A complete production line from Design, Own Processing centre for spareparts & worktable, Importing Japan Sanyo and Yaskawa motors, Importing TaiWan Brand controlling system, Finishing operation, Inspection centre, Testing team and Professional vacuum packing with Fumigated wooden case.

3. A complete set of CNC Spring coiling machine & wire bending machine to processing the wire diameter from 0.15mm to 8.0mm, especially including the new technology of the Camless machine with wire rotation function and the applying of the Camera Spring Length Gauge on the Compression Spring Machine

4. Quality first, QA/QC is one of the most important departments in our company.

5. Over 150 skilled worker, 48 technicians and one group of 20 engineers.

6. Main market: Europe(UK, Italy, Sweden, Romania, Poland, Estonia, Russia,Turkey)

Africa(South Africa,Egypt,Tunisia),

Asia (Korea, India, Malaysia, Vietnam, Iran, Thailand),

South America (Brazil, Argentina, Colombia, Cuba, Mexico)

7. We have established customer oriented quality management system, strengthen lasting innovation and enhance after-sale services.

Our principle is "Quality first, Customer paramount, Keep improving"

Give your project to us, we “KCT” are going to do the best profession to you.

| Packaging Detail:Vacuum packed&Standard fumigated wooden case |

| Delivery Detail:15-20working days after receiving 30% deposit |