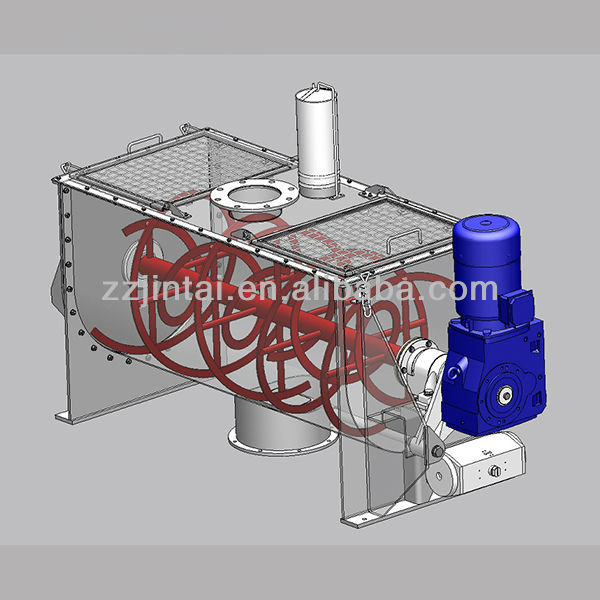

Jintai Horizontal Ribbon Blender

| Application:powder materials: solid- solid, solid- liquid | Materials:stainless steel | Nominal volume:200L ~ 10000L | Loading coefficient:40% ~ 70% |

| Discharge device:manual (pneumatic) flap, arc, rotary, ball, butterfly valve | Additional device:liquid spray device, heating/ cooling jacket | Certification:CE / ISO9001:2008 | Power supply:220 - 415V, 50/60Hz |

How ribbon blenders work?

Ribbon Blendersconsist of a U-shaped horizontal trough and a specially fabricated ribbon agitator. A ribbon agitator consists of a set of inner and outer helical blades. The outer ribbon moves materials toward the center of the trough, and the inner ribbon moves the materials toward the outside of the trough. The ribbon also rotates at approx. 50rpm, thus moving materials both radially and laterally to insure thorough blends in short cycle times. Ribbon agitators are used for blends that will be between 40 and 70% of the rated capacity of the blender.

Ribbon blenders mainly serve in below industries:

Technical parameters of JHRB series ribbon blenders:

| Model | JHRB | ||||||

| Nominal volume(m3) | 0.1 | 0.3 | 0.5 | 1 | 2 | 3 | 4 |

| Loading coefficient | 40% ~ 70% | ||||||

| Motor power (kw) | 3 | 4 | 5.5 | 11 | 18.5 | 22 | 22 |

| Out-form dimension (mm) | 1080*758*615 | 1550*812*1015 | 1675*1142*1300 | 1970*1497*1550 | 2480*1651*1805 | 2880*1896*2055 | 3026*1946*2205 |

| Weight(kg) | 330 | 780 | 955 | 1400 | 2500 | 3300 | 3600 |

Note: A ribbon blender’s full working capacity typically corresponds to a batch level right around the height of the top ribbon. At rest, materials shouldn’t be above the ribbon agitator. Overfi lling can lead to long blending cycles or unsatisfactory mixes.

....

| Packaging Detail:inner packing: plastic film;outer packing: plywood |

| Delivery Detail:7 days after payment received |