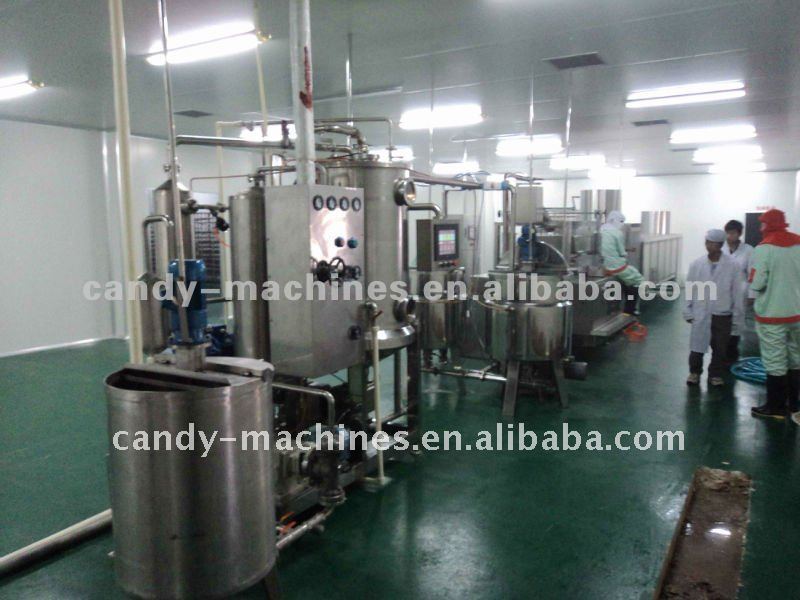

Jelly Candy Production Line / jelly production process line

| Place of Origin:Zhejiang China (Mainland) | Brand Name:ESM | Model Number:LJC | Application:Candy |

| Production capacity(5g candy):360-720kg/h | Power consumption:30-45KW | Consumption of compressed air:500L/min | Pressure of compressed air:0.4-0.6Mpa |

| Steam consumption:450kg/h | Steam pressure:0.6-0.8Mpa | Water consumption:2200L/h | Area for the machine:13X(2~2.8)X2.7m |

| Weight of machine:6-9.5Tons | Certificate:ISO 9001:2008 |

Jelly Candy Production Line is an advanced candy machine at present time.It integrates mechanical and electric all in one.This machine has the features of high output,high quality,various types,convenient operation,compact structure,and highly automatic control.It can produce high quality jelly candy. The product of this machine possess smooth surface and nice taste,being popular with both domestic and overseas customers.

Technique parameter

| Model | LJC-II | LJC-III | LJC-IV |

| Production Capacity(5g candy)(kg/h) | 360 | 500 | 720 |

| Power consumption(cooker)(kw) | 16 | 23 | 23 |

| Power consumption(depositor)(kw) | 14 | 15.5 | 22 |

| Consumption of Compressed Air(L/min) | 500 | 500 | 500 |

| Pressure of Compressed Air(Mpa) | P=0.4-0.6 | P=0.4-0.6 | P=0.4-0.6 |

| Steam consumption(kg/h) | 450 | 450 | 450 |

| Steam pressure(Mpa) | P=0.6-0.8 | P=0.6-0.8 | P=0.6-0.8 |

| Water consumption(L/h) | 2200 | 2200 | 2200 |

| Area for the Machine(m) | 13X2X2.7 | 13X2.5X2.7 | 13X2.8X2.7 |

| Weight of Machine(Tons) | 6 | 7.5 | 9.5 |

The brief introduction of ESM

Ningbo East Sea Machinery Co., Ltd. is a leading company in China confectionary field, who has integrated function as design and develop new products, manufacture and sale , installation, technical training and after-sales service, It’s also a state high-tech enterprise. The reliable product quality, world's leading R & D capability, innovation and quality service, has make it been the leading level in the confectionary field.

Company is located in Ningbo, China -an important industrial city, which covers an area of 35 million square feet, has a long history with 20 years,which has research and development center, product test factory and production factory. The advanced technology, complete inspection means, is a strong guarantee of high quality products and brand reputation both at home and abroad market. At present, the company has been successfully introduced the 6S and the rationalization activities, and developed a comprehensive training system for employees. The company will further implement other management activities, which will further enhance the effective management and product quality.

Technology is a leading and rapidly growing force in the accumulation of a valuable source, the company has strong technology development platform, set up R & D center, has a strong R & D experts team. Company has been qualified ISO9001: 2000 international quality system certificate and CE certificate for some products.

At present, our products has not only supplied to the famous domestic brand enterprise in China(For example,Cadbury Group, HSUFUCHI FOOD, Golden Monkey, Oishi-TM Group,Want Want Group, Sisterma Food, Yake Food, Guan Sheng Yuan Group,PERFETTIVANMELLE Confectionery CO.,LTD.,Wrigley Group,ROGUETTE Company,General Mills(Haagen-Dazs maker etc), but also exported to Germany, Japan (for example, KANRO company), Indonesia (for example, candy companies MAYORA who has used our machines to make famous brand Kopiko), Thailand (for example URC company), India, the Middle East, Mexico, South Korea, Singapore and other countries. In recent years the company has continuously intensified its efforts to develop new products, such as Jelly line, Chocolate depositing machine, Die forming machine, lollipop cooling tunnel, some lab machine of cookers and so on.

| Packaging Detail:wooden or film package + 40'HC |

| Delivery Detail:70 days |