Italian gelato hard ice cream make

ice cream make, gelato batch freezer, 1.CE approved, 2.SGS certificate, 3.Refrigerant type:R404A, 4.Efficient and hygienic - details see: https://www.machineto.com/italian-gelato-hard-ice-cream-make-10051615

| Condition:New | Place of Origin:Jiangsu China (Mainland) | Brand Name:PROSKY | Model Number:VITA 60 120 |

| Application:Ice Cream | Voltage:220V/380V | Power(W):7950 | Weight:280KG |

| Dimension(L*W*H):740 * 990 * 1250mm | Certification:CE,SGS | Warranty:1 year | 2 speeds:intelligent computer system |

| easy operation:one key control | discharge quickly:big discharge spout | discharge completely:speical design beater | after cooling cycle:ice cream consistency |

ice cream make,ice cream making machine, Batch freezer ,Gelato machine

Specifications:

| Gelato hard ice cream machine | ||||

| Model | VITA 10 30 | VITA 15 45 | VITA 20 60 | VITA 60 120 |

| Cylinder | 7 ltr | 10 ltr | 15 ltr | 35 ltr |

| Mix added/batch(min) | 1.5 kg | 2.5 kg | 3 kg | 8 kg |

| Mix added/batch(max) | 5 kg | 7.5 kg | 10.5 kg | 24.5 kg |

| Mix added/hour(min) | 10 kg | 15 kg | 20 kg | 60 kg |

| Mix added/hour(max) | 30 kg | 45 kg | 60 kg | 120 kg |

| Control system | Hardness control system | |||

| Agitator design | replaceable blades with self regulating leaf spring | |||

| Batch time/min | 8-10 | 8-10 | 9-12 | 10-15 |

| Production capacity/hour(min) | 12 ltr | 21 ltr | 28 ltr | 72 ltr |

| Production capacity/hour(max) | 42 ltr | 63 ltr | 90 ltr | 140 ltr |

| Electricity specification/volt | 220/380 | 220/380 | 220/380 | 220/380 |

| Electricity specification/Hz | 50 or 60 | 50 or 60 | 50 or 60 | 50 or 60 |

| Electricity specification/Ph | 1 or 3 | 3 | 3 | 3 |

| Refrigerant type | R404A | R404A | R404A | R404A |

| Compressor | Tecumseh | Tecumseh | Tecumseh | Bitzer |

| Condenser | water / air | water / air | water / air | water / air |

| Rated power | 5300w / 5700w | 6100w / 6500w | 7800w /8200w | 10100w / 10500w |

| Frame type | Floor | |||

| Construction | powder coated against corrosion | |||

| Outer Panel Material | stainless steel AISI 304 | |||

| Net weight | 452 lbs / 205 kg | 505 lbs / 229 kg | 633 lbs / 287 kg | 774 lbs / 351 kg |

| Gross weight | 507 lbs / 230 kg | 562 lbs / 255 kg | 683 lbs / 310 kg | 871 lbs / 395 kg |

| Size W * D * H(with wheels) | 19.7 * 25.6 * 55.1 inch | 19.7 * 25.6 * 55.1 inch | 19.7 * 25.6 * 55.1 inch | 23.6 * 31.5 * 57.1 inch |

| 500 * 650 * 1400mm | 500 * 650 * 1400mm | 500 * 650 * 1400mm | 600*800*1450mm | |

Packing size W * D * H | 23.6 * 29.5 * 61 inch | 23.6 * 29.5 * 61 inch | 23.6 * 29.5 * 61 inch | 27.6 * 35.4 * 63 inch |

| 600*750*1550mm | 600*750*1550mm | 600*750*1550mm | 700*900*1600mm | |

| Agitator Advantages | ||||

| 1,New agitator running steadier to improve work efficiency and lessen the abrasion of scrapers and interior cylinder | ||||

| 2,Special design reduces input minimum significantly | ||||

| 3,Stronger shear force churns more thoroughly | ||||

| 4,Blade advantages | ||||

| Blades with auto-compensation function | ||||

| Scraping material more thoroughly | ||||

| Easy to dismantle | ||||

| Cleaning more conveniently | ||||

| 5,Unique design improves freezing efficiency | ||||

| Craft Advantages | ||||

| 1,Complete flat machine roof where can hold other devices, such as mix boiler | ||||

| 2,Pre-posed water hose to clean the machine easily and safely | ||||

| 3,Over-thick door steel plate increases the door rigidity and heat preservation effect, and prevents transformation | ||||

| 4,Unique feed port avoids feed block and mix spurt out, resulting in all along genuine good taste ice cream | ||||

| 5,Improved bigger dispensing opening from which the ice cream can be extracted artistic and faster with energy conservation | ||||

| 6,Cylinder door opening angle limited design prevents the lid and front panel broken | ||||

| 7,Special durable freezing cylinder with high smoothness and low wearing capacity discharges the material thoroughly with no stick | ||||

| 8,Rectangular material receiving mat is proper for the hopper | ||||

| 9,Arc-shaped material receiving guards users against accidents | ||||

| 10,Inclined control panel is durable and easier to operate | ||||

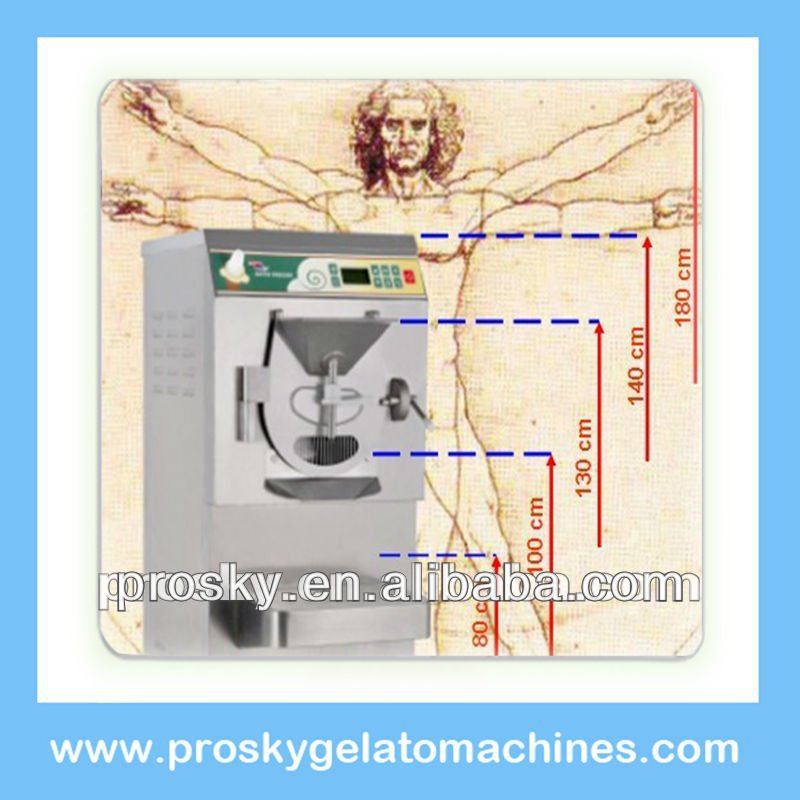

| 11,Every size for the machine is designed in regards to ergonomics | ||||

| 12,Door handle is lengthened to save labor | ||||

| 13,Rationally designed heat dissipation holes on the side panels allow two machines stay close seamless. | ||||

| 14, High-balanced pulley is durable and easy to be removed. | ||||

| 15,With the unique noise reduction design, the machine is steady and low-noise. | ||||

| 16,Electronic intelligent switch operates conveniently and safely. | ||||

| Intelligent Control System | ||||

| 1,The whole working process of the machine is controlled by intelligent chips. | ||||

| 2,Large LCD display shows the working condition generally | ||||

| 3,Running status is graphical on the display clearly and easily | ||||

| 4,Concise and easy operation with one key | ||||

| 5,Individual homogeneous key complies to mix a variety of materials at any time. | ||||

| 6,Key indicator lights clearly suggest the current working condition. | ||||

| 7,With intelligent safe door control, the machine will shut down to protect the users once the door is opened. | ||||

| 8,One key cleaning switch makes machine cleaned more safely and labor saved. | ||||

| 9,Intelligent power emergency control on the control panel is aesthetical | ||||

| 10,SS (soft start) system can protect the machine program and all parts. | ||||

| 11,Post cooling is adopted while the ice cream is being extracted, which helps to maintain consistency of the ice cream. | ||||

| 12,Self-diagnosis system is adopted and shown on the LCD display, available for long distance interventions. | ||||

| 13,Pre-stored automatic defrosting program. | ||||

| 14,Intelligent 5+N that the same material can be made into 5 common flavors and multiple individual flavors to meet various requirements. | ||||

| Packaging Detail:polywood case packaging suitable for sea and air shipment |

| Delivery Detail:within 15-30 days after your deposit |