ISO approved mineral powder ball press machine for sale

| Place of Origin:Henan China (Mainland) | Brand Name:Guoxin | Model Number:GQ | Condition:New |

| After-sales Service Provided:Engineers available to service machinery overseas | color:green, blue etc | motor power:5.5-90 KW | capacity:1000-1500kg/h |

| diameter of roller:290-1000 mm | warranty:1 year | certificate:ISO9001:2008 | sphere size:30-60 mm |

| final shape:round, oblate, pillow-like etc |

Mineral ball press machine for mineral powder/coal dust,powder/iron power

1 > Ball press machine feature:

1.high efficienty

2.apply for many kinds of powder like charcoal,coal,mineral,metal.etc.

3.make round type or pillow type or oblong type charcoal ball.

4. the products have high density, high strength, high hardness

2>Ball press machine working principle:

1.mineral ball press can press charcoal/coal powder, charcoal dust, iron/mineral/ powder, etc into ball or pillow-shaped charcoal.

2. This series of coke ball type pressure machine will pass the power on to the two pressure roller through the reducer. The two sides and roll rotation, in both the rotating roll.

3. Natural materials to enter the ball roll mode, with the roll rotation, material pressure on a small become larger. When the material to the two rollers rotating line contact point,thepressure of materials has reached the peak. Tremendous pressure in the role of line, the materials become a finished product from the powder ball.

3>Ball press machine data informations

| Model | Capacity (T/h) | Power | Roller diameter | Reducer | Size |

| AMS-290 | 1~3 | 5.5kw | 290mm | ZQ300 | 1.1×0.8×1.3m |

| AMS-360 | 4~6 | 7.5kw | 360mm | ZQ350 | 1.3×1.15×1.6mm |

| AMS-430 | 6~8 | 11kw | 430mm | ZQ500 | 1.4×1.3×1.7mm |

| AMS-500 | 7~9 | 18.5kw | 500mm | ZQ650 | 1.6×1.8×2.1mm |

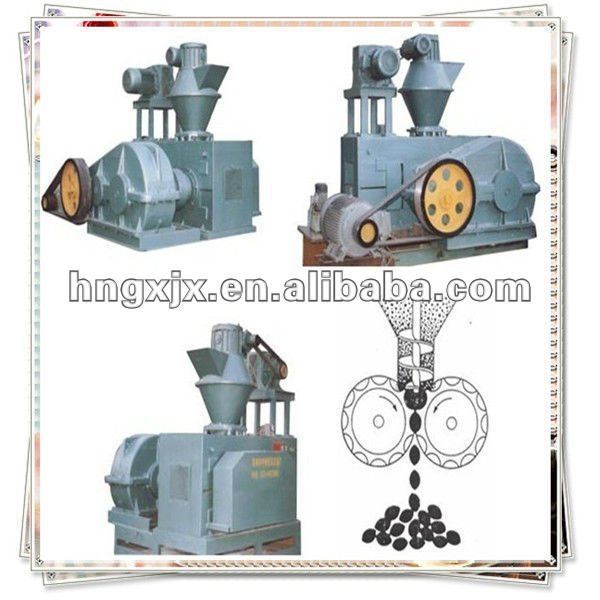

4>machine image:

Working principles

[1]The main motor shaped belt, spread to reducer, gear reducer the coupling, spread to ZhuDongZhou again by a pair of open type gear, to guarantee two roller synchronization.

[2]Passive roll hydraulic oil cylinder piston resist, by the hydraulic loop and liquid control valves and the accumulator guarantee system pressure, and the material is the storage silo quantitative equipment evenly into the molding machine hopper.

[3]Through the hopper the regulation on the disc adjustment, make the material of uniform to roll into the middle, patterned reverse operation of the roller compression of the unit material molding pressure turned from small to big.

[4]In the center of roller in attachment molding pressure reaches maximum, material over divides, molding pressure to make materials into smaller quickly take off the ball state, smooth to take off the ball.

| Packaging Detail:standard container, in nude, wooden case, at the buyer's option |

| Delivery Detail:20 days after receiving prepayment |