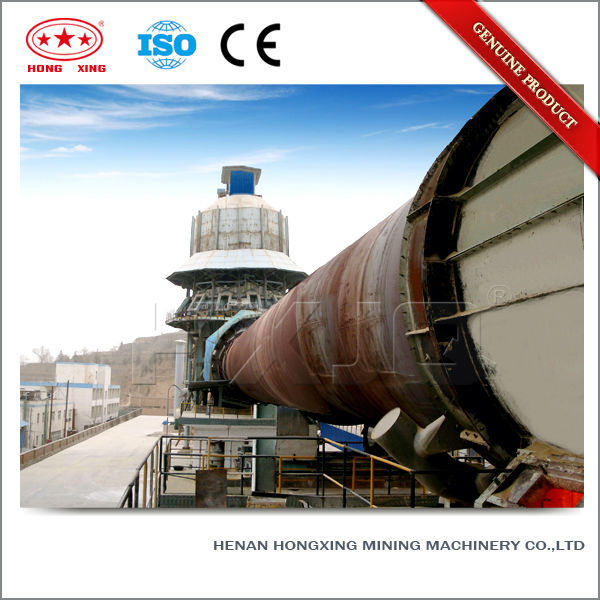

ISO and CE Certified High Efficiency Hot Sale Lean iron Chromium Ceramic Sand Kiln

| Condition:New | Production Capacity:180-10,000t/h | Place of Origin:Henan China (Mainland) | Brand Name:Hongxing |

| Model Number:Hongxing rotary kiln | Voltage:220, 380 | Power(W):55-950*2kw | Dimension(L*W*H):Refer to specification |

| Weight:150-1660t | Certification:ISO9001:2008, CE | Warranty:1 year | After-sales Service Provided:Engineers available to service machinery overseas |

| Energy:Saving | Structure:Reasonable | Application:Cement,construction | Maintenance:Convenient |

| Running cost:Low | Installation:Under technical guidance | Operation:Easy | Running State:Stable |

| Market:Africa, Europe, Asia,etc | Adaptability:Strong |

ISO and CE Certified High Efficiency Hot Sale Lean iron Chromium Ceramic Sand Kiln

I.Special technology used in Lean iron Chromium Ceramic Sand Kiln

1.Unstructured gridworks for cement clinker rotating kiln.

The unstructured grid that applies in the actual production of cement rotary kiln is composed by arbitrary triangular or tetrahedral grid, under normal circumstances, this kind of structure model is also referred to as a hybrid grid; because of its measurement ability, irregular change, good flexibility and practical applicability, we put it into production of cement rotary kiln.

2.Full specifications, large model.

3.Planing of steel plate and overall annealingof cylinder eliminate welding stress and prevent deformation.

4.Green technology.

5.Air leakage coefficient can be controlled at 15% or less.The system uses full negative pressure operation, soot emissions is below the national environmental emissions standards.

6.Advanced automatic control system, which consists of base control systems and process automation control system, reliable and stable.

-------------------------------------------------

II.Application of Lean iron Chromium Ceramic Sand Kiln

1. Its technical performance and workings state determines the quality, yield and cost of enterprise products to a great extent.

2.In building materials industry, in addition to calcine cement clinker, horizontal kiln is also used to dry calcined clay, limestone and slag; in refractory materials production, raw materials calcined by rotary kiln has stable dimension and great strength.

3.In the beneficiation process, use horizontal kiln to take magnetization roasting for iron ore can change the weak magnetic to be strong magnetic, so that facilitate the separation.

4. In the chemical industry, horizontal kiln is used to calcine soda, phosphate fertilizer, barium sulfide etc., with advantages of low energy consumption and small electricity.

5. Horizontal kiln is the host of cement production, commonly known as "the heart of the cement factory".

-------------------------------------------------

III.Process characteristics of Lean iron Chromium Ceramic Sand Kiln

1, using energy-saving way of calcination.

2, dust removal system makes flue gas and dust keep clever collocation, flue gas emissions meet standards.

3, reasonable process, compact layout.

4, scientific process, the waste heat can be most effectively used.

5, novel design, easy adjustment.

6, distributing equipment has unique structure and uniform distributing quantity.

7, uniform wind supplying maintains good furnace condition.

8, advanced control in furnace condition, short adjusting time.

9, high automation level.

------------------------------------------------------------------------------------------------------------------------------------

Why Choose Us

1.We Are Factory ( NOT Dealer )

All machineries from Henan Hongxing Mining Machinery Manufactory are made by ourselves, with lower price, good quality and assured full after service.

So please buy machine from factory.

-----------------------------------

2.Training & Service

Pre-sale services: enthusiasm

We provide you with the prophase plan, process flow design and manufacturer equipment according to your special demand.

Sale services: servant

Send technicians to the jobsite for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

In addition, we provide one-year warrantee to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.

-----------------------------------

3. If you are new for this business, we will help you

Many thanks for your trust; we can provide you with design scheme for complete production lines, spot inspection and operator training according to your demands and the conditions of applied spot, we can help you choose the right equipments.

-----------------------------------

4. We’d like to recommend a suitable type for you and send you a best quotation.

-----------------------------------

5. Delivery

We have developed long and good relationship with many shipping agents. Ocean freight partners are:APL, COSCO, OOCL, CSCL, MSC, etc. and train shipping is also available. The perfect shipping way and best service with lowest price are always provided for customers.

| Packaging Detail:Standard export containers,bare main machine, motors and small parts are packed in wooden cases. |

| Delivery Detail:Within 10-20 working days after receiving the down payment. |