Iron Ore Beneficiation Sellers

| Place of Origin:Henan China (Mainland) | Brand Name:Xingbang | Model Number:10-800 | Condition:New |

| type:iron ore mining equipment | application:iron ore mining equipment | certification:ISO9001:2000, CE,CQC | warranty:for the whole using life |

| Iorn ore beneficiation installation:our engineers guide installaton | Spare parts:Supplying the whole using life | Beneificiation test:we provide | capacity:100t/d, 250t/d, 300t/d, 500t/h etc |

Iron Ore Mining Equipment

Iron Ore Processing Plant

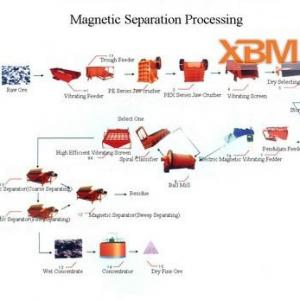

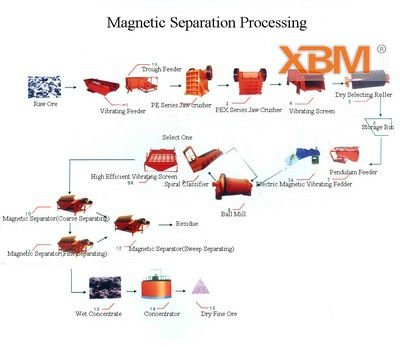

First, ore crushing and grinding: concentrator generally coarse broken, broken in three sections of broken and fine crushing of iron ore crushing process. Rough broken 1.2m or 1.5m multi-cycle crusher, in breaking with 2.1m or 2.2m Standard cone crusher, fine break by 2.1m or 2.2m short head type cone crusher. Through the thick broken ore, the block is no more than 1m, and then through the medium and fine crushing and screening into the small particle size of ore 12mm to send the final product in the grinding slot.

Grinding process: iron ore grinding process, the majority of two-stage grinding process, a small processing plant to use more grinding process. As a result of fine grinding and then screening of new technology, in recent years, has two grinding concentrator Grinding into three sections. grinding equipment used in general is relatively small.

Iron Ore Mining Equipments:

Iron ore production line entails four main steps:

1. Crushing and grinding of the ore.

2. Concentration or dressing of the ore.

3. Reduction to free metal.

4. Purification or refining of the metal.

Iron ore beneficiation processing:

Photo of the plant in working:

Thank you for taking the time to go through our Iron Ore mining process. If there are any question, inquiry or comments, please feel free to contact us.

| Packaging Detail:standard exporting container |

| Delivery Detail:10-30 working days |