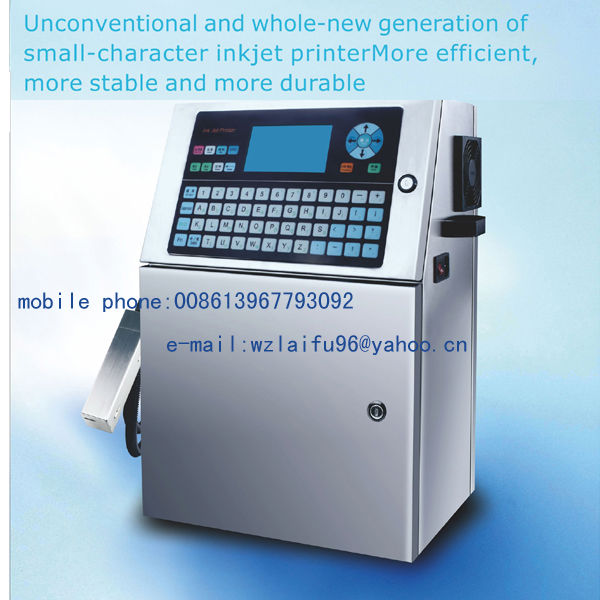

Inkjet printer | production date Inkjet printer |GraphicInkjet printer |trademark printer

| Type:Inkjet Printer | Condition:New | Plate Type:production date Inkjet printer | Place of Origin:Zhejiang China (Mainland) |

| Brand Name:feilaifu | Model Number:LF2000 | Usage:Paper Printer,Label Printer,Card Printer,Tube Printer,Bill Printer,Cloths Printer | Automatic Grade:Automatic |

| Color & Page:Multicolor | Voltage:220 | Gross Power:..... | Dimensions(L*W*H):.... |

| Weight:... | Certification:..... | After-sales Service Provided:Overseas third-party support available |

Dear User,

This Manual contains very useful information on how to operate your lnk-Jet Printer. Please read this Manual carefully. This edition of the document includes most of the changes and the descriptions contained therein correspond to the printers that are equipped with this software version.

As the machine and options can be customised, the product

delivered to you depends on your specific order .Therefore some

descriptions or illustrations may differ slightly from your equipment.As we need to keep pace with new technological advancement, we reserve the right to introduce changes in the design and technical solutions adopted. In view of the above, no data, illustrations or description shall make grounds for any claims.Should your printer be equipped with options that are not described or illustrated in the Manual or should you have additional queries after having read the Manual, please contact any WLD In-jet Systems representative for more information.

2

Safety Requirements

All efforts have been put into designing this printer carefully and making it safe and reliable. However, safe operation of the device is conditioned by the user's awareness of, and obedience to the following safety rules and precautions.

The unit should be operated by the staff that has been trained. It is recommended that the operation of the printer is supervised.

1.A fire extinguisher designed to extinguish electrical equipment and flammable solvent fires must be placed within easy reach of the unit.

2.The unit must not be operated in rooms where an explosion hazard exists.

3.

C |

No overprints can be made on products whose temperature exceeds 100°at the time of printing.

4.No open fire or spark producing devices are allowed in the area where the unit operates.

5.Power supply cord must be connected to a socket where an earthed pin is used. The efficiency of earth should comply with the applicable standards. Additionally,in some cases the printer -housing earth terminal needs to be connected appropriately (according to the instructions given in section2.3.4 Connections).

6.

3 |

As high voltage occurs in the printer,make sure that all manipulations in the electrical part of the system and inside the head are performed after power has been switched off.

7.The outlet of the head must not be directed towards persons, animals or accidental objects during in order to avoid splashing anybody or anything with ink.

8.Protective clothes and possibly protective glasses need to be warn by persons performing any work on the ink system.

9.No plastic vessels should be used to do the washing as they collect static electricity. Metal vessels are recommended.

10.Air contaminated with solvent should be carried away to the outside of the building through a clear duct.

11.No ink,.solvent or wash-up (or waste fluid remaining after the head head has been washed) should be left in open vessels as these inflammable fluids may ignite from accidental sources of fire.

4 |

WARNING:Times New Roman

Static electricity collected by people (on their plastic clothes or in their hair, for example) may spark-over to ink or wash-up vessels when the have been left open. The ink and wash-up are inflammable and may ignite! Therefore you approach the open vessels containing inflammable fluids,discharge static electricity by touching the metal printer housing or another metal object is connected to the earth.

In the case of accident ...

' When ink or solvent spills occur,the spilled fluid should be wiped with a piece of absorbent material and then disposed of in compliance with fire,health and safety at work(HSE)regulations.

' If the clothing has been splashed,remove it as soon as possible.

' Should the eyes eyes or skin get irritated:

EYES need to be rinsed with running water for at least 15 minutes, then you should see your eye doctor.

SKIN needs to be washed with water and soap.

5 |

Principle of Operation

Overprints are produced in the following ways:

1 Acontinuous ink jet is broken into droplets.

2 Then the droplets are charged and deflected in an electric field.

3 Every label consists of drop-wide vertical rows.

4 The droplets are deflected on the vertical plane. Every droplet within a row is broken off the continuous jet,then charged and deflected while passing under a high-voltage electrode.

5 Objects to be labelled move in front of the print head and vertical rows are printed one by one to complete the entire label.

6 Uncharged droplets fall into a gutter and from there are pulled back and returned to the ink system cylinders.

This method of printing is applied to all CIJ printers.

6 |

Frame and fixing

Picture 1 :frame chart

1.The printer should not be tilted,turned“up side down”or shaken up.

2.The printer must not be installed in rooms full of dust or vapor or rooms with corrosive gas.

3.The printer should be no direct contact with oil, water or other fluid.

4.The printer must not be installed power supply cord preferred, must not be connected with other high power equipments (electrical motor,for example). Additional, the printer-housing earth terminal needs to be connected appropriately.

5.The printer is preferred to be installed in rooms with good ventilation.

6.The print head holder must not be installed where much vibration or shocks happens.

7.The production line or the conveyor under the head holder must move without strong vibration.

8.

7 |

The surface of targeted objects must be dry and of no dust.

Starting the Printer

In this section we will introduce some operations as followed:

Switching the Printer On /Off

Operating the Printer

Start Print / Stop Printing

| Packaging Detail:Export wooden box |

| Delivery Detail:Payment to the account with Arrange the shipment |