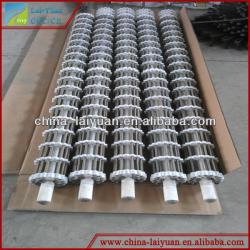

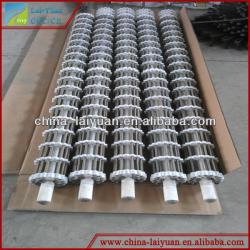

Industrial Straight Bobbin Ceramic Heater

| Condition:New | Type:Infrared Heater | Power Source:Electric | Place of Origin:Jiangsu China (Mainland) |

| Brand Name:Laiyuan | Model Number:LY-CBH-03 | Dimension(L*W*H):Customized | Voltage:380V |

| Power(W):Customized | Certification:CCC | Warranty:1 Year | Name:Straight Bobbin Ceramic Heater |

| Material:Ceramic&Resistance | Length:Customized | Power:Cutomized | Sample day:Withi 7 days |

Product name: Straight Bobbin Ceramic Heater

1) Rated working temperature 1000 degrees, the heating wire material is Cr20Ni80 or 0Cr21Al6Nb, the surface working temperature can reach 1200 degrees. The ceramic heater use this material the highest temperature can reach 1000 degrees, the support is Altitude Aluminum ceramic heating element.

2) If with protection, it’s cold drawing seemless thin thickness stainless steel tube, the material is 1Cr25Ni20Si2 or 1Cr25Ni35Si2,this material has high temperature oxidation-resistance, carburization resistance and high temperature strength;

3) Rated working temperature 1200 degrees, the heating wire material is 0Cr27Al7Mo2 or 0Cr21Al6Nb, the surface working temperature can reach 1400 degrees, the ceramic heater use this material the highest temperature can reach 1250 degrees, the support is corundum ceramic heating element.

If with protection, it’s cold drawing seemless thin thickness stainless steel tube, the material is Fe-Ni-Cr-Al-Re alloy, this material has super high-temperature oxidation-resistance, carburization resistance and high temperature strength; and woke on 1300 degrees for long time , anti-oxidation on 1360 degrees for short time .

Ceramic Bobbin Usage:

1) Avoid to heat over the temperature and overload for long time

2) When the furnace temperature higher than 400 degrees, avoid to be cold immediately.

3) Unload and load the material can’t touch the ceramic heater

4) Pay attention to the red and blue buttons when the furnace on work, and change regularly when on thermal insulation

5) Pay attention to the instrument meter, and deal with in time when the furnace temperature is not matched with the meter.

6) The furnace Capacity over 100KW, it’ll be better to fix the ammeter for check in every heat area.

Protection:

1) After using three to four months, take the ceramic heater, and pour-out the dust in the ceramic heater, and tuner the heater 180 degree.

2) Pay attention to the positive and negative pole, and two to four months make a change.

3) Can touch and hit the heater when take it out.

4) Check the screw regularly for the oxidation looseness,Laiyuan.

Photos for reference:

| Packaging Detail:Foam&Wooden box for Straight Bobbin Ceramic Heater |

| Delivery Detail:Within 7 days for Straight Bobbin Ceramic Heater |