IGBT medium frequency induction furnace for steel, iron, metal and alloy melting

| Condition:New | Type:Induction Furnace | Usage:Melting Furnace | Place of Origin:Hunan China (Mainland) |

| Brand Name:unionsum | Model Number:USM402 |

IGBT Medium Frequency Induction Furnace

Introduction

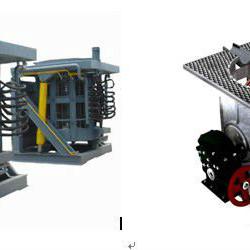

IGBTmedium frequency induction furnaceis mainly used for melting of ordinary carbon steel, alloy steel, cast steel, cast iron, nonferrous metals and alloy and so on, with the advantages of high efficiency, fast melting and easy to operate.This new type of power supply is a voltage source inverter with series resonant output.The inverter part uses advanced IGBT transistors. The performance of this new power is superior to the thyristor frequency power supply in many ways.

Features

1.The start-up performance is vey good.Itisaseries resonant circuit to solve the difficulty in starting ofSCR MF.

2.It israrelygeneratedhigh harmonic and littlepollution togrid.Switchgear and transformers donot heat. So it willnot interfere the operation ofelectronicequipmentin the workshop.

3.It hashigh reliability.IGBT transistors are produced by Simon Kang Company in German. And electrolytic capacitors are produced by Japan's Hitachi Company. Drive board is a Swiss production. It has been not any quality problem since it is put into the market.

4.Itsaves energy.Power consumption of0.5 t300 kwmedium frequency induction furnaceis about650kWh /ton, and0.75 tons to 3tons medium frequency induction furnace is about600kWh /ton,savingabout28%thantheold-fashionedthyristormedium frequency induction furnace.

5.It uses water exchange bellows switch as water circulation system. Distilled water circulating in thecirculation can use by long-term, and no scaling and blocking, so it isgreatlyreducing the failure, savingmaintenance costs.

6.It maintains a constant power output in the smelting process. It differs in the modeof SCRIF adjustment. SCRIFisby regulating theDC output voltage, but our product is by adjusting thefrequency and not affected by furnace charge, so it keepsa constant power output in the smelting process.Inparticular,theproduction of stainless steel, copper, aluminum and othernon-magneticmaterial, itdemonstratesits superiority of fastmelting rate, less charge burning lost, so it is energy-savingbetter, reducingthecostofcasting.

7.It is convenient in use and maintenance. Thecircuitstructure of IGBT frequency power supply is simple and protected well, with perfect display functions, so it can find out thepoint of failure quickly,easy to maintain.

Parameters

| Packaging Detail:packed to suitable for long way transportation |

| Delivery Detail:within 30days after recieved deposit and workable P.O. |