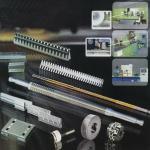

HSS Parallel Side Spline Broaches with TiN high quality

| Place of Origin:Chongqing China (Mainland) | Brand Name:YQ | Model Number:Type1-3 | Machine Type:broach machine |

| Type:Broach | Coat:TiN/TiAlN |

HSS Parallel Side Spline Broaches

Description:

1.HSS Parallel Side Spline Broaches

2.Material: HSS (M2/M35)

3.Coat:TiN/TiAlN

4.Type: Type1-Type3

TypeⅠⅡ

| Key Amount | Nominal Dia. | Key Width | Overall Length | Broaching Length |

| 4 | 15~22 | 4~8 | 425~745 | 10~80 |

| 6 | 16~90 | 4~20 | 400~1635 | 10~120 |

| 8 | 36~72 | 6~12 | 500~1580 | |

| 10 | 26~125 | 3`18 | 560~1690 | |

| 16 | 38~82 | 3.5~7 | 750~1635 | 30`180 |

| 20 | 92~102 | 6~7 | 1125~1635 | 30~120 |

TypeⅢ

| Key Amount | Nominal Dia. | Key Width | Overall Length | Pre-Broaching Hole Dia. |

| 6 | 25~50 | 6~12 | 550~1400 | 10~120 |

| 8 | 36~50 | 6~9 | 570~1190 |

Material: HSS (M2/M35)

1.HSS: High Speed Steel

1).Total alloying elements: 10~25%

2).Vc=25~30m/min

3).Red hardness: 600°C

4).Type: (1) W18CR4V (2) W6Mo5Cr4V2 (3) W6Mo5Cr4V2Co5, W6Mo5Cr4V2Co8

2.M2 (W6Mo5Cr4V2)

3.M35 (W6Mo5Cr4V2Co5)

Coat: TIN/TIALN

1.TIN

1).TiN is a kind of high hardness, abrasion resistance, wide application of coating materials.

2).TiN is the ideal of low-speed cutting tool coating materials, can reduce the adhesion of cutting edge materials, reduce the cutting force, increasing the feed quantity, improve the machining accuracy, maintain the stability of cutting geometry, improve the surface quality of workpiece.

2.TIALN

1).TIALN is a new coating material which has high hardness, good oxidation resistance, small friction coefficient and has been found broad prospects in high speed cutting.

2).Function:

| Coat Material | HV | GPa | °C |

| TIN | 2300 | 260 | 600 |

| TIALN | 3300 | 380 | 900 |

Note:

The broaches are divided in to three types:

1.Type 1 Spline Broaches

2.Type 2 Chamfer-Spline Combination Broaches

3.Type 3 Round-Spline Combination Broaches

| Packaging Detail:oiled paper+carton+wooden case or as requirment. |

| Delivery Detail:within 20 days |