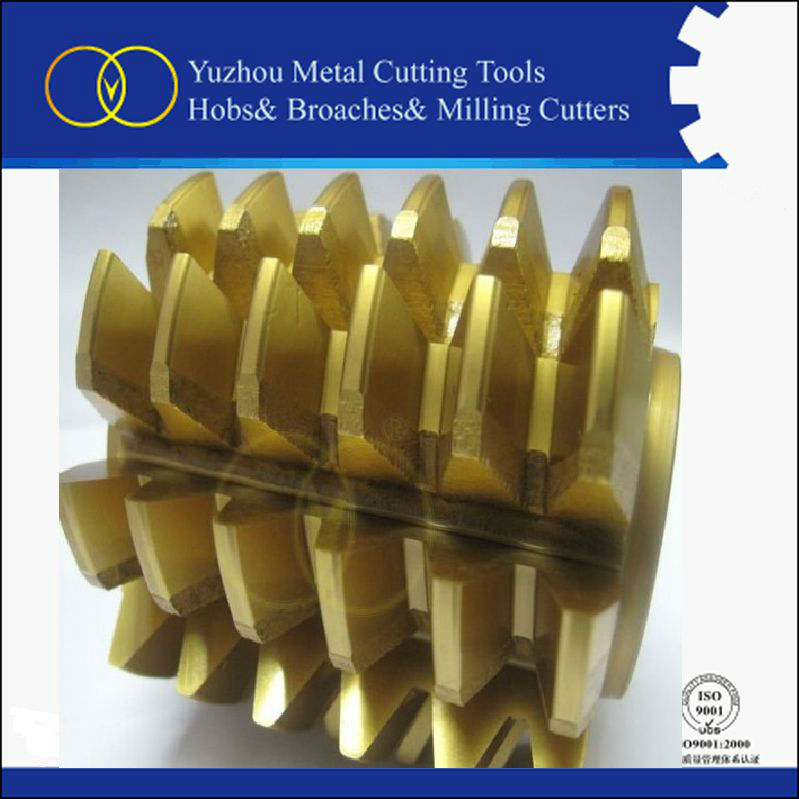

HSS Module 6.5 Standard Gear Hob

| Condition:New | Type:Spline Hobs | CNC or Not:Normal | Place of Origin:Chongqing China (Mainland) |

| Brand Name:YZ | Model Number:Involute Spline Hobs | large module hobs m6.5:large module hobs | types gear hob cutters:types gear hob cutters |

| module 6.5 hob cutters:module 6.5 hob cutters | large module hob cutter:large module hob cutter | cutter specification:hob cutter specification | DIN 3972 gear hob cutter:DIN 3972 gear hob cutter |

| DIN 3968 gear hob cutter:DIN 3968 gear hob cutter | hss hob cutter:hss hob cutter | hss fine pitch gear hob:hss fine pitch gear hob | timing belt pulley hob:timing belt pulley hob |

Technical Specification

1. Module:6.5

2. Material:HSS Steel M2(W6Mo5Cr4V2)

3. Accuracy:Class AA

4. Outside Diameter:110mm.

5. Bore Diameter:32mm.

6. Length:100mm.

7. Number of Slots:9

8. Pressure Angle:20°

9. Lead Angle:4°03′

10.Coating:TIN

Technical Parameters of Standard Hob Cutters Series

Products Display

Coating and Material

. For material

We provide you materials as follows for you reference

1.High speed Steel M2

.Component: W6Mo5Cr4v2,

.Delivery Hardness ≤ 255HB

.Harding Temperature: 1220-1240 Degrees

.Hardness ≤ 63

.Common Used Material

2. High Speed Steel M35(S705) Provided by the Bohler in Austria.

.Co4.8%

.Hardness≥ 64HRC

.High Toughness HSS

.High wearability

.High Pressure Resistant

.Resistance to Sintering

.Better Material

3. Powder Metallurgy

.The Best Material

. For Coating

We Provide you the following coating for your reference.

. TIN Coating

Microhardness(HV): 2300

Coefficient of Friction(COF): 0.40

Innerstress(Gpa): -2.5

Maximum Reaction Temperature: 600 Centigrade

Color: Golden Yellow

Coating Structure: Monolayer

. TiAIN Coating

Microhardness(HV): 3300

Coefficient of Friction(COF): 0.30-0.35

Innerstress(Gpa): -1.3/-1.5

Maximum Reaction Temperature: 900 Centigrade

Color: Purplish Gray

Coating Structure: Nano-struture

Wide Range of Option

Providing the Following Hobs

. Standard Gear Hobs

. Pre-shaving Hobs

. Pre-grinding Hobs

. Involute Spline Hobs

. Parallel Side Spline Hobs

. Worm Wheel Hobs

. Sprocket Hobs

. Chamfering Hobs

Production Process & Brief View of the Factory

Chongqing Yuzhou Mechanical Tools Factory is a professional manufacture, which is famous for standard and non-standard Hobs, various types of broaches and milling cutters. It was established in 1993, with 20 years' history in metal cutting tools' field.

Packing &Shipping

. For Packing

.The products are wrapped with Oiledpaper and the bittle box as inner packing.

. The products are wrapped with Cartons as outside packing

. If you have special requirements, such as wooden cases, please mention that in advance.

. For Shipping

.We provide air transportation and ocean transportation.

.Port of Chongqing is our port of loading, because the factory closes to Xiyong Integrated Free Trade

Zone and Cuntan Integrated Free Trade Zone with 1 hour.

ContactInformation

| Packaging Detail:Oiledpaper + Cartons + Wooden Cases or as you required |

| Delivery Detail:with 20 Days |