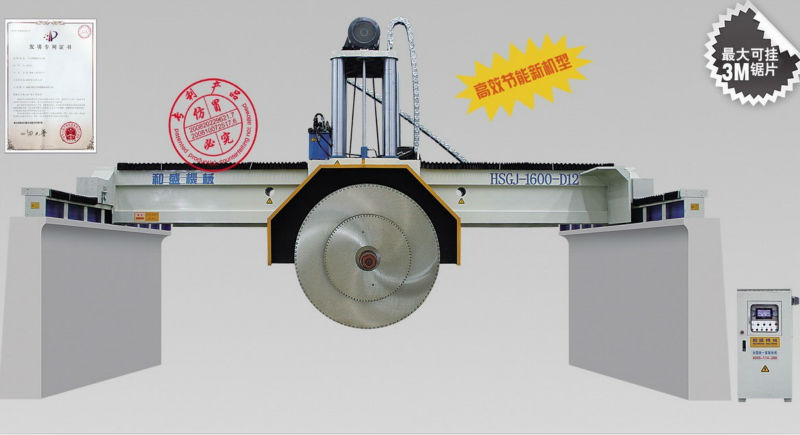

HSGJ-1600-D12 Hydraulic Bridge Saw & stone cutter for granite

| Condition:New | Type:Bridge Saw | Use:Granite | Production Capacity:250ã¡ |

| Place of Origin:Fujian China (Mainland) | Brand Name:Hesheng | Model Number:HSGJ-1600-D12 stone cutter for granite | Voltage:the voltage of the HSGJ-1600 (stone cutter ) can be customized |

| Power(W):55-90kw | Dimension(L*W*H):9200*5000*6800mm | Weight:19T | Certification:ISO9100 |

| Warranty:Half year | After-sales Service Provided:Engineers available to service machinery overseas | Name:stone cutter for granite | No. of blade:12-18pcs |

| Blade combination ways:Big-Small & Big-Medium-Small | Max. blade diameter:1650-3000mm | Crossbeam Length:8000mm | Left/right working range:3500-4800mm |

| Side beam length:5000mm | Front/back working range:2500mm | Up/down working range:1400mm | Shaft diameter of Spindle box:100-120mm |

HSGJ-1600-D12 Hydraulic Bridge Saw & stone cutter for granite

1/The HSGJ-1600( stone cutter for granite ) configured withautomatic PLC control system.The cutting slab size and quantity are programmed from the control panel and visualized on touch screen.

2/Maximal diameter of blade is3000mm( single blade only of HSGJ-1600-D12),width of slab can be1300mm.

3/Both impported and homemade High-precision electrical components are used,such as PLC(JANPAN),Linear guide(Taiwan),Hydraulic Cylinder(Germany)......and so on.

4/The patented "Hydraulic Locking"technology and total cast iron construction structure,enable this very sturdy machine of NO vibration during cutting,hence to maximizing its cutting accuracy.

5/OPTIONAL:main motion motor with a inverter controlled for variable speed.

6/CUSTOMIZATION:a horizontal blade can be customized for cutting marble block.

MORE DETAILS

1/ Patented looking device is uesd to reduce the spacing of machine from friction, this will maximum increase the cutting precision.(Alternative)

2/“Hydraulic locking device” which using on the end frame of crossbeam, can further improve the stability of cutting, and markedly improve flatness of cutting and the using-life of blade tools. Patented Looking Device is used to reduce the spacing of parts of machine from friction, this will maximum increase the

cutting precision.

3/Linear guide path imported from Taiwan is used on the transverse moving structure(HIWIN), this will ensure the high stability of cutting, endure it is service time, easy to replace.

4/A guiding polymer materials (Teflon, Brand Dupont) was used on the contact surface between up/down column and seat . Such

guiding material is rolling into a circular storage pits, in less oil or oil under the conditions of space off to work with a low coefficient of friction, wear resistance and long service life, etc..

5/Up/Down oil cylinder using the combined oil seal , imported from German , imported German, composited with a flexible seal ring, two retaining rings and two block-oriented ring which is a five-pieces set of piston seals and with much several times of service life compared with other common sealing.

6/Cutting mode, quantity and thickness of slab, feeding depth can be view and set thru PLC computer control system(Both imported and homemade high-precision electrical components are used)

7/A new composite materials called "nano-nylon" cloth which with the characteristics of waterproof, dustproof, anti-rally of anti-wear , was used; and the use of detachable zipper will enable a easy replacement of it .

8:Up/Down Column movements are lubricated by grease (Butter) which only need to be added up to only once every three months. It will significantly reduce maintenance frequency.

9/Sliding ways of up/down system are quantity proceed by completely new grinding machine, for the purse of high precision and quality.

10/Use CNC boring lathe to process the hole of sliding way column and headstock, to ensure the concentric and stability.

11/Oil Tank Assembly: including Oil Pump, Electromagnetic Valve and other components adopted are imported from Taiwan.

12/Adjusting device of running wheel

13/The blade cover of the HSGJ-1600(Hydraulic bridge saw)made up of 3mm steel-plate, painted with asphaltum for anti-rust.

| Packaging Detail:HSGJ-1600-D12 (Stone cutter) are Solid packing suitable for long-way transportation by sea . |

| Delivery Detail:HSGJ-1600-D12 (Stone cutter) will be ready after 35 days |