Hot Selling Spiral Grader with CE certified used in Ore dressing Plant

| Condition:New | Type:Sprial Separator,china Spiral Grader | Place of Origin:Henan China (Mainland) | Brand Name:QY |

| Model Number:spiral grader used in ore dressing plant | Voltage:380V | Power(W):According to the engineer caculation | Dimension(L*W*H):According to the model you choose |

| Weight:2.7---85.3t | Certification:CE,SGS,ISO | Warranty:12 months | After-sales Service Provided:Engineers available to service machinery overseas |

| Performance:stable and reliable | Technical support:Yes | Drawing:we supply | Spare parts:Perennial Supply |

| factory visit:welcome | Installation:engineer installation | motor:china famous brand, or as require | color:as require |

| Business type:manufacturer |

Hey, friend, I'm so glad you can focus on the products of our company.

We are direct factory. Our company can customize professional product according to the client's desire. We are designed to raise the quality, improve the efficiency, cut down the capitalized cost, reduce labor, as well as supporting the production line.

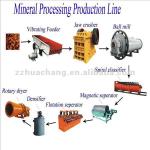

Spiral grader with CE certified

Spiral grader is the main equipment in mineral dressing plants, used to grade solid particle of different density and speed in liquids. With grinders, it can form a closed circuit, which is used to do the pre-grading and check grading, and granule declining and dehydrating in ore washing. It's divided to single spiral and double spirals; According the difference of spiral's depth in overflow surface, it's divided to high weir type and sinking type.

Check the bolt of each component before using, make clear its degree of tightness, lift the screw shaft, run under zero load, shift the lifting handle, drop down slowly, make the deposit in sink active, finally work, and then the bearing shafts in both axle heads shall be filled up with grease oil regularly.

Application of the mineral spiral grader Spiral graderis widely used in classifying:

lClassify ore sand and fine sludge in gravity ore separation plant

lForm a closed circulation with the ball grinder for ore-sand separation in the ore

separation plant

lRemove sludge/water at the ore separation process

lClassify the ore pulp according to granularity during the metal ore separation process

Working Principle of themineral spiral grader Spiral grader is consists of water channel, gearing, spiral department, lifting gear, lower support, ore discharge valve. Different solid granularities have different gravity and thus have different dropping speed. The fine ore granularities floating in the water will overflow and the big ones will sink to the bottom and discharge from the upper part by spiral pushing. It can filter the granularities from the machine and then spin the rough particles to charging part by spiral vane and discharge the fine granularities from the overflow pipe. The base of the machine adopts a channel steel and the body adopts welded steel plate. The water inlet of spiral axle and axle head adopt pig iron cover for wear proofing and long life operation. The lifting equipment has two types, manual control and electric control.

Advantages and performances of themineral spiral grader Spiral grader has the following advantages:

lSimple structure, reliable working conditions and convenient operation.

lLight in weight, rust and corrosion resistant

lHigh recovery, high efficiency, and precise separation

lStrong adaptability to fluctuation of feeding amount, density, size and grade

lSimple installation and Minimal maintenance requirements.

lLow operating cost and long operating life

Mineral spiral grader in our workshop

Mineral spiral grader in our customer site

Technical Parameters of themineral spiral grader

| Kind | Type | Spiral Diameter (mm) | Water trough length (mm) | Spiral rotation speed(r/min) | Capacity(t/d) | Motor Power(kw) | ||

| Sand return | Overflow | Drive | Hoist | |||||

| High weir type | FG7.5 | 750 | 5500 | 6~10 | 340~570 | 65 | 3.0 | Manua |

| FG10 | 1000 | 6500 | 5.0~8.0 | 675~1080 | 110 | 5.5 | Manua | |

| FG12 | 1200 | 6500 | 5.0~8.0 | 1170~1870 | 155 | 5.5 | 1.5 | |

| FG15 | 1500 | 8400 | 4.0~6.0 | 1830~2740 | 235 | 7.5 | 2.2 | |

| FG20 | 2000 | 8400 | 4.0~6.0 | 3240~5400 | 400 | 11 | 2.8 | |

| FG24 | 1400 | 9210 | 3.6 | 4650~7450 | 580 | 15 | 3.0 | |

| FG30 | 3000 | 12500 | 3.2 | 11650 | 890 | 22 | 4.0 | |

| 2FG12 | 1200 | 6500 | 5.0~8.0 | 2340~3740 | 310 | 5.5×2 | 1.5×2 | |

| 2FG15 | 1500 | 78400 | 4~6.0 | 3660~5480 | 470 | 7.5×2 | 1.5×2 | |

| 2FG20 | 2000 | 8400 | 3.0~5.5 | 7780~11880 | 800 | 11×2 | 2.8×2 | |

| 2FG24 | 2400 | 9210 | 3.6 | 13600 | 1160 | 15×2 | 3×2 | |

| 2FG30 | 3000 | 12500 | 3.2 | 14600~23400 | 1785 | 45 | 4×2 | |

| Sinking type | FC12 | 1200 | 8400 | 5~8 | 1170~1870 | 120 | 7.5 | 2.2 |

| FC15 | 1500 | 10500 | 4.0~6.0 | 1830~2740 | 185 | 7.5 | 2.2 | |

| FC20 | 2000 | 12900 | 2.0~5.5 | 3895~5940 | 320 | 15 | 2.8 | |

| FC24 | 2400 | 14200 | 2.5~4.0 | 4650~7450 | 455 | 18.5 | 4 | |

| FC30 | 3000 | 14300 | 3.2 | 11625 | 705 | 30 | 4 | |

| 2FC15 | 1500 | 10500 | 4.0~6.0 | 2280~5480 | 370 | 7.5×2 | 1.5×2 | |

| 2FC20 | 2000 | 12900 | 3.0~5.5 | 6480~11800 | 640 | 11×2 | 3×2 | |

| 2FC24 | 2400 | 14200 | 3.67 | 9300~14900 | 910 | 18.5×2 | 4×2 | |

| 2FC30 | 3000 | 14300 | 3.2 | 23300 | 1400 | 45 | 4×2 | |

Our after-sale service

Starting on the day of the received products, within a year, if there is quality problem can free replacement new products, if because of the improper use of your product damaged, we will solve the problem for you through online video.

About us lHenan Qunying Machinery Manufacture Co., Ltd.was founded in 1961, which is specialized in metallurgy, mining, building materials, chemicals, coal and electric power, providing crushers, ball mills, processing equipment, pelleting and sintering equipment, cement and building material equipment, coal washing equipment, mineral equipment and hoisting equipment.

lOur company has passed ISO quality certification,CE, quality system certificate and are also AAA grade reputable enterprise

lOur equipments have been exported to more than 100 countries all around the world andgain a good reputation both at home and abroad. We are an enterprise with good faith in China and foreign and the focus among industrial enterprises in China.

Certification of our company

Plants of our company

Production equipment of our company

Foreign customers of our company

Installation site of our company

Are you satisfied the introduction on above? Please contact us with the information quickly!

| Packaging Detail:1.Small One Packed in Boxes(standard wooden or iron case) 2.Large one with Nude Packing, meeting the demands of export and seaway 3.As your request |

| Delivery Detail:Within 30--60 working days since the date of receipt of deposit |