Hot sale sawdust dryer machine with ISO certification

| Condition:New | Type:Drum Drying Equipment | Place of Origin:Henan China (Mainland) | Brand Name:Hengxing |

| Model Number:3x25m | Voltage:380v or as requirement | Power(W):75kw | Dimension(L*W*H):diameter 3m length 25m |

| Weight:110t | Certification:CE, SGS, ISO9001:2008 | Warranty:One year | After-sales Service Provided:Engineers available to service machinery overseas |

| Application:building material, metallurgy, slag, coal, clay, sawdust | Installation:As our engineer's guidance | Body Material:Q235 | effective volume:176.7 cu. mtr |

| Dust catcher:included | Electric motors:famous brand |

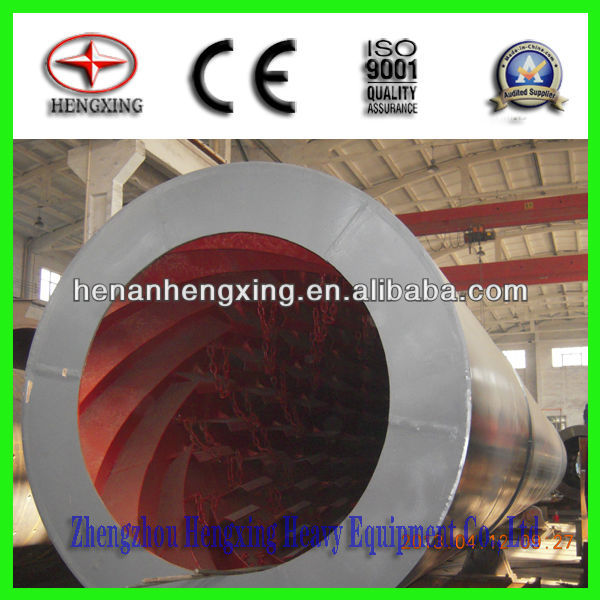

1. Brief introduction of rotary sawdust dryer machine

Rotary drum dryer is widely used for drying slag limestone, coal powder, slag, clay, etc. Dryer can also be used in building materials, metallurgy, chemical and cement industry. Dryer mainly consists of dryer body, raw material feeding plate, driving and supporting device, seal ring, etc. Dryer can be generally divided into four types, they are: rotary dryer, triple-drum dryer, indirect heat transfer dryer, vertical dryer. Different kind of dryer has its own characters and advantages, the specific choice of a special dryer depends on different elements.

2. Rotary sawdust Dryer, rotary dryer machine

Rotary dryer is a kind of highly efficient, stable and reliable heating drying equipment (dryer), it is designed by Hengxing heavy equipment to dry materials of high moisture or strong stickiness. Rotary dryer has a better performance than tube bundle rotary dryer, blade rotary dryer. Rotary dryer has the features of big capacity, low energy cost and high efficiency.

1).Rotary sawdust dryer machine is used for drying materials with a certain humidity or granularity in milling of food ,chemical ,ores, building materials, metallurgy and chemical industry;

2). Rotary sawdust dryer machine has a strong adaptability of materials and it can dry various materials. The operation is very simple and liable. So this kind of coal slime dryer has playing important role in various industries;

3).Rotary sawdust dryer machine is applied in materials like coal slurry, mud, filter gypsum, muddy, high-moisture swell soil, electroplate mud, and other materials and areas.

Material to be dried enters the dryer, and as the dryer rotates, the material is lifted up by a series of internal fins lining the inner wall of the dryer. When the material gets high enough to roll back off the fins, it falls back down to the bottom of the rotary dryer, passing through the hot gas stream as it falls. This gas stream can either be moving toward the discharge end from the feed end (known as co-current flow) of the rotary dryer, or toward the feed end from the discharge end (known as counter-current flow) of the dryer. The gas stream can be made up of a mixture of air and combustion gases from a burner, in which case the rotary dryer is called a direct heated dryer. Alternatively, the gas stream may consist of air or another (sometimes inert) gas that is preheated.

Rotary sawdust dryer machine technical parameter:

Model | diameter (mm) | Drum length (m) | Main reducer | Speed (r/min) | Production capacity (t/h) | Power (kw) | Weigh(t) | Volume(m3) | |

| Model | Ratio | ||||||||

| Φ1.0X10 | Φ1000 | 10 | JZQ450-16-11 | 6.73 | 1-3.8 | 5.5 | 7.5 | 7.85 | |

| Φ1.2X12 | Φ1200 | 12 | ZL50-16-1 | 5.8 | 1.8-5.5 | 11 | 13.8 | 13.31 | |

| Φ1.5X12 | Φ1500 | 12 | JZQ500-111-2F | 16.46 | 4.8 | 4-9 | 15 | 22.3 | 21.2 |

| Φ1.5X 15 | Φ1500 | 15 | ZQ50-1611-2 | 16.46 | 4.8 | 4-10 | 18.5 | 28.8 | 26.5 |

| Φ1.8X14 | Φ1800 | 14 | JZQ650-111 | 18.84 | 3.2 | 6-12 | 30 | 39.8 | 48.22 |

| Φ2.2X16 | Φ2200 | 16 | ZJQ750-111 | 31.5 | 3 | 10-23 | 37 | 51 | 60.1 |

| Φ2.2X18 | Φ2200 | 18 | JZQ750-111 | 31.5 | 3 | 10-25 | 37 | 53.3 | 70.43 |

| Φ2.4X20 | Φ2400 | 20 | ZL85-13-1 | 27.16 | 2.83 | 20-40 | 45 | 78.4 | 90.43 |

| Φ2.8X24 | Φ2800 | 24 | ZL100-16-1 | 31.5 | 2.59 | 20-45 | 55 | 97 | 147.8 |

| Φ3.0X20 | Φ3000 | 20 | ZL100-16-1 | 41.54 | 2.6 | 25-48 | 55 | 102 | 141.3 |

| Φ3.2X25 | Φ3200 | 25 | ZLH115 | 41.54 | 2.1 | 30-55 | 110 | 148 | 201 |

3. Triple-drum Dryer, rotary sawdust dryer machine

Triple-drum dryer is used to drying humidity particle materials, such as yellow sand used by industry, variety of sand which used in foundry industry, blast furnace slag which used in cement industry of building materials, chemical, food, compound fertilizer, copra, etc. Small particle size aclay. According to requirements of the water in the products after drying. The water content 1-0.5% or less can be achieved after process.

1). The triple-drum rotary dryer uses telescope-feed structure, dry material quickly.

2). Simple design, self-insulation, improve the heat efficiency of triple-drum rotary dryer to exceed 80%

3). The triple-drum dryer is of delicate structure, steady operation

4). The triple-drum dryer has a good drying performance, coal consumption less than 8kg 1ton material.

5). The fuel can be coal oil, natural gas, etc, granule and powder material less than 20mm can be dried in the triple-drum dryer.

6). The triple-drum sawdust rotary dryer reduces land area for 50% compared with single drum dryer, so construction investment is saved 50%, power consumption saved 60%.

7). Finished product moisture of triple-drum sawdust dryer can be adjusted depending on clients’ requirement.

8). Triple-drum dryer is of lower outlet temperature, longer using life of dust removal.

9). Triple-drum dryer is driven by tug, not gear and pinion.

10). Finished product temperature of triple-drum dryer is lower than 60°C, packing can be done continuously

Rotary sawdust dryer machine technical parameter:

| Specification Parameters | Dia 2* 4.5m | Dia2.2*5m | Dia2.5*8m | Dia2.7*6.5m | Dia3.0*6.5m | Dia3.2*7m | Dia3.6*8m | Dia4.2*8m |

| Outside tube diameter | 2 | 2.2 | 2.5 | 2.7 | 3.0 | 3.2 | 3.6 | 4.2 |

| Outside tube length | 4.5 | 5 | 6 | 8.5 | 6.5 | 7 | 8 | 8 |

| Cylinder volume | 14.13 | 18.99 | 29.43 | 37.19 | 45.92 | 56.27 | 84.39 | 110.78 |

| Cylinder speed | 4-10 | 4-10 | 4-10 | 4-10 | 4-10 | 4-10 | 4-10 | 4-10 |

| The highest influx of air temperature | 700-750o C | 700-750oC | 700-750oC | 700-750o C | 700-750o C | 700-750oC | 700-750oC | 700-750oC |

| capacity | 13-18 | 15-23 | 20-28 | 24-33 | 35-40 | 40-60 | 55-75 | 70-120 |

| motor power | 5.5*2 | 7.5*2 | 5.5*4 | 7.5*4 | 11*4 | 15*4 | 18.5*4 | 22*4 |

4. Indirect heat transfer dryer, rotary sawdust dryer machine

The indirect heat transfer dryer supplied by Hengxing is widely used in building materials, metallurgy, and chemical industry, cement plant for drying of limestone slag, coal powder, slag, and clay stone. The indirect heat transfer dryer mainly consists of rotary body, raw material feeding plate, driving and supporting device, seal ring and so on. It has reasonable structure, fine workmanship, high capacity, low consumption and convenient operating and so on. therefore, it is greatly favored by customers.

1).By direct or indirect heating, the heating efficiency can reach up to 95%

2).Operating under high temperature and low oxygen to avoid materials being self-burning or exploding when drying

3).Big drying capacity, highly industrialize and low cost

4).Low amount of air are required to save tail gas handling cost

5).Rotating part rotates slowly and low abrasion wear

6).Firm construction and durable

7).Compact structure, big heating area, and smaller installation area

rotary sawdust dryer machine technical parameter:

| Items | Inside diameter of outer shell | Inside diameter of inner shell | Shell length | Shell cubage | Shell | Lifting blade | Highest inlet air | Dimensions |

| Shell diameter *shell length | mm | mm | m | m3 | Obli-quity | form | Tem.oC | |

| Ø1.5*15m | 1500 | 500 | 15 | 20.27 | 3-5% | Lifting form | 850 | 16.2*2.7*2.7 |

| Ø1.5*17m | 17 | 22.97 | 18.2*2.7*2.7 | |||||

| Ø1.5*19m | 19 | 25.68 | 20.0*2.9*2.9 | |||||

| Ø1.8*21m | 1800 | 650 | 21 | 35.91 | 3-5% | Lifting form | 850 | 22.5*2.7*2.7 |

| Ø1.8*23m | 23 | 39.33 | 24.5*2.9*2.9 | |||||

| Ø1.8*25m | 25 | 42.75 | 26.5*2.9*2.9 | |||||

| Ø2.2*21m | 2200 | 800 | 21 | 58.1 | 3-5% | Lifting form | 850 | ---- |

| Ø2.2*23m | 23 | 63.61 | ||||||

| Ø2.2*25m |

Our certificate for rotary dryer machine:

rotary dryer machine Products scene:

You are welcome to visit our factory to see our rotary sawdust dryer machine at any time!! rotary dryer in stock.

You are welcome to our factory! Call Rocky:0086-18837173732

| Packaging Detail:in container or bulk goods, spare parts packed in wooden case |

| Delivery Detail:20 days after first payment |