HOT SALE Professional Manufacturer Type 2.4*18m with Capacity 50 TPH Rotary Dryer for Drying Sand

| Condition:New | Type:Drum Drying Equipment | Place of Origin:Henan China (Mainland) | Brand Name:Libo |

| Model Number:2.4*18m | Voltage:380V | Power(W):30 kw | Dimension(L*W*H):dia 2.4*18m |

| Weight:78.4t | Certification:ISO | Warranty:1 year | After-sales Service Provided:Engineers available to service machinery overseas |

| colour:customizable | volume:81 cubic meter | transfers barrel diameter:2400mm | transfers barrel length:18m |

| gradient:3-5 degree | rotational speed:1.5-6 r/min | price:negotiable |

Φ2.4×18Rotary Dryerfor Drying Sand

1. Introduction of Dryer for Drying Sand

Rotary dryers can be widely used to dry various materials, such as metallic and nonmetallic mineral, clay in cement

industry and coal in coal mine, etc, and it is quite easy to master the process measures. China is one of the major

countries manufacturing dryer and is also the best selling manufacturer in the world.

Henan Libo Mining Machinery Co., Ltd is one of the best sellers in those companies manufacturing dryers in China. As a professional manufacturer with many years' experiences in mining machinery, we can produce all kinds of dryer machinessuch as Rotary dryer, Limestone dryer, Drum dryer, Cement rotating dryer and so on.

All the machines can be customized as long as you provid some information such as name of raw material, size-consist, property, moisture content, temparature, end use, capacity per hour, etc.

2. Application of Dryer for Drying Sand

Rotary dryer is used for drying materials with humidity or granularity in the industries of mineral dressing, building material, metallurgy and chemical. Rotating dryers can be used for drying many kinds of materials with convenient and reliable operation; therefore, it has been widely used in those industries above on.

3. Working Principle of Dryer for Drying Sand

Materials are sent to hopper of rotary dryer by belt conveyor or bucket elevator, materials enter the barrel installed with slope to horizontal line from the higher side, and hot air enters the barrel from the lower side, and then materials and hot air mix together. Materials go to the lower side by gravity when the barrel is rotating. Lifters on the inner side of barrel lift materials up and down in order to make materials and hot air mix completely, which is designed to improve the producing efficiency of rotary dryer.

Main technical parameters of Dryer for Drying Sand

| type | transfers barrel diam(mm) | transfers barrel length(m) | gradient(°) | rotational speed(r/min) | weight(t) | power(kw) | volume(m³) |

| Φ0.6*8 | Φ600 | 8 | 3°-5° | 8 | 5.1 | 4 | 2.26 |

| Φ0.8*10 | Φ800 | 10 | 3°-5° | 7.2 | 6.9 | 4 | 5.02 |

| Φ1.0*10 | Φ1000 | 10 | 3°-5° | 6.73 | 7.5 | 5.5 | 7.85 |

| Φ1.2*12 | Φ1200 | 12 | 3°-5° | 5.8 | 13.1 | 11 | 13.31 |

| Φ1.5*12 | Φ1500 | 12 | 3°-5° | 4.8 | 22.3 | 15 | 21.2 |

| Φ1.8*14 | Φ1800 | 14 | 3°-5° | 3.2 | 45.8 | 30 | 48.22 |

| Φ2.2*18 | Φ2200 | 18 | 3°-5° | 3 | 50.3 | 37 | 70.43 |

| Φ2.4*20 | Φ2400 | 20 | 3°-5° | 2.83 | 78.4 | 45 | 90.43 |

| Φ2.8*24 | Φ2800 | 24 | 3°-5° | 2.59 | 97 | 75 | 147.8 |

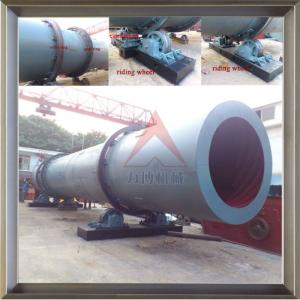

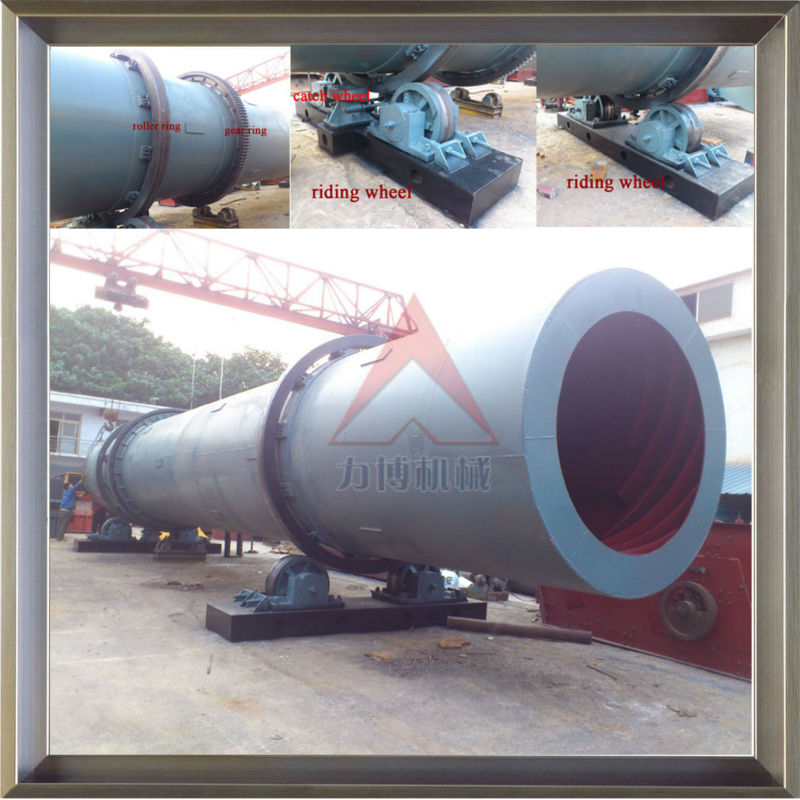

Pictures of Dryer for Drying Sand

| Packaging Detail:Export standard |

| Delivery Detail:15-30 days |