Hot sale! Hard-wearing Briquettes Machine

| Application:Processing agricultural waste | Production Capacity:400kg/h | Place of Origin:Henan China (Mainland) | Brand Name:Guoxin |

| Model Number:YBJ series | Condition:New | Warranty:1 year | After-sales Service Provided:Engineers available to service machinery overseas |

| Raw materials:straw, rice husk, sawdust, wood chips, cotton husk... | Shape of charcoal:Round, quadrilateral, hexago.. | Burning time:about 3 hours | Type:energy saving machine |

| Use:dispose of Agro-forestry waste | Certification:CE, OEM, ISO certificate |

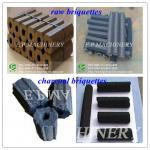

Brief Introduction of Briquettes Machine

- The Biomass briquettes machine is the process of converting substantial biomass wastes into high density and energy concentrated bio fuel briquettes.

- Biomass briquettes are one kind of ultimate green energy source of renewable energy. And the biomass briquettes are non~conventional source of energy, renewable in nature, eco~friendly, non~polluting and economical.

- In the whole process no binders and chemicals are needed, 100% natural ensured. The higher density, the higher heating value, the biomass briquettes calorific value is up to 3000~4000 Cal/kg.

- Compared with fire wood and loose biomass, the briquettes show much higher heat because of lower moisture and higher density.

Biomas briquettes machine are widely used in boilers, refractory, chemicals, home heating, etc. They become more and more popular as fuel all over the world.

Raw material

Any type of Agro-Forestry waste can be used. But the Moisture Content Should be about 8-12%, grain size is below 5*5mm.

Saw dust • Wood Chips • Wood logs • Tree branch • Wheat Straw • Peanut-shell • Rice husk • Sugar Cane bagasse • Coffee Husk • Paddy Straw • Sunflower Seed Husk • Sunflower Stalk • Reeds • Cotton plant Stem • Tobacco waste • Mustard Stalk • Jute waste • Bamboo Dust • Tea waste • Palm husk • Soybeans husk and many other agro and forest wastes.

Working principle

Biomass Briquette Machine make the biomass material into briquettes. After the well prepared of raw material, briquetting is easy at right operation of biomass briquette press. When the molding tube of machine rise to over 300 centigrade, the material was puted continuously into feeding hole of briquetting press, the raw material will be pressed clavate wood under the high temperature and high pressure by molding tube. First, the color of finished clavate wood maybe a little dark even black,but after a while, the color will be light to normal level coming out of biomass briquette machine.

The rough process for producing the charcoal briquettes is as follows:

1. Crush the raw materials into small pieces(around 3MM diameter) by Crusher(Hammer Mill);

2. Dry the crushed materials by Dryer, make the crushed material's moisture content below 12%;

3. Put the dried materials into the briquette machine to make charcoal briquettes.

4. Put charcoal briquettes into the Carbonization Stove to make the sawdust briquettes into coal briquettes

(final products, this step is for optional, if you do not need charcoal, no need to use this carbonization).

Welcome to contact me to consulte more product information. \(^o^)/~

| Packaging Detail:container standard |

| Delivery Detail:Within 12 working days after receiving 30% prepayment |