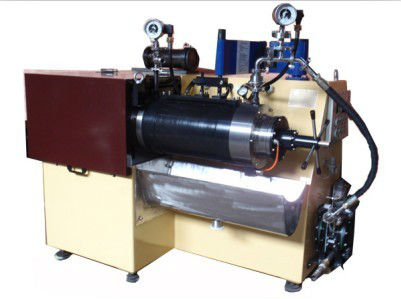

horizontal sand mill

| Condition:New | Type:Ball Mill | Product Type:Paint | Place of Origin:Shanghai China (Mainland) |

| Brand Name:ROOT | Model Number:RT-10B Pin-type Bead Mill | Voltage:Specific size | Power(W):18.5KW |

| Dimension(L*W*H):2000*800*1400mm | Weight:1000 KG | Certification:CE | Warranty:1 year |

| After-sales Service Provided:Engineers available to service machinery overseas | Name:horizontal sand mill | Output Capacity(KG/H):100~300 | Volume(L):10 |

Pin-type Bead Mill

Application:

widely used in high effect grinding for coating, pigment, inks, medicine, sensitive film, pesticides, foods, non-mining, electronic paste, papermaking, cosmetics and so on.

Characteristic:

a. High efficient, about twice efficiency of the same volume disc-type bead mill;

b. Grinding pin and chamber made from high strength and high anti-wearing alloy. Special structure and reasonable layout improve the grinding effect great. Standard configuration adopt anti-wearing alloy, PU, ceramic and other material for option according to customers’ requirement

c. Grinding chamber volume can be adjusted

d. Import cartridge mechanical seal with double ends, safer than other machine

e. Triple cooling system. Cooling both in chamber and two-ends and rotors and shaft to ensure keep the material temperature below 45°C(with 10°C chill water)

f. Grinding chamber made from high anti-wearing alloy. Lossless and rust free. And non metal chamber line for option;

g. With pressure protection, can be adjusted according to the viscosity of the grinding product

h. Separation device: dynamic separator with self clean function to avoid block

i. Grinding medium: zirconia beads, high abrasive resistance

j. Efficiency: fineness can reach 50nm

Technical parameter:

| Model | Volume(L | Motor Power(KW | Output Capacity(KG/H) | Medium Size(mm) | Weight (KG) | Dimension (mm) |

| RT-10B | 10 | 18.5 | 100~300 | 0.3~2.0 | 1000 | 2000*800*1400 |

| RT-20B | 20 | 22 | 150~400 | 0.3~2.0 | 1050 | 2000*1100*1400 |

| RT-30B | 28 | 30 | 200~450 | 0.3~2.0 | 1100 | 2000*800*1400 |

| RT-50B | 45 | 45 | 250~600 | 0.3~2.0 | 1800 | 2000*1100*1500 |

| RT-80B | 80 | 55 | 600~1200 | 0.3~2.0 | 2000 | 2000*800*1800 |

| RT-120B | 120 | 90 | 1000~2000 | 0.3~2.0 | 2200 | 2100*2200*1000 |

product pictures (for reference only):

Figure 2: equipment cavity internal images

Remark: Nitrate type grinding structure,the company abandoned the many manufacturers choose renewable powder or micro powder sintering,Choose carbide tungsten carbide material of ultrafine powder through one-time high temperature sintering,Higher hardness, better wear resistance.Using hollow shaft structure,Circulating water cooling,To achieve better cooling cooling effect.After we summarize and precise calculation that we have obtained Nitrate rod size,angle of installation and The clearance between nitrate rods and cylinder wall.More reasonable, to ensure that equipment grinding efficiency is higher,Nitrate rod and cylinder longer service life.

Figure 3: grinding cylinder body images

Remark: Grinding cylinder outside the cylinder abandon the bad practice of Many manufacturers choose stainless steel,ROOT chooses die steel,After technology for heating processing,Not deformation,Wear resistance, corrosion resistance, long service life.

Figure 4: equipment operation panel pictures

Remark: Abandoned the disadvantage of many manufacturers design rigid and the poor safety performance,Not only in the aspect of safety design for full explosion-proof structure, and the water pressure protection, pressure protection, thermal protection, pressure protection,When occurrence problem of equipment operation environment, the equipment can appear alarm,And automatically stop working (The device always is in proper working condition, effectively prolong life);The overall design humanization, panel has accumulated ammeter, the equipment running time, etc(Refer to car mileage design, the effective maintenance periodically to remind customers to ensure that equipment performance and life span)Intuitive showing the operation of the equipment.

Figure 5: equipment oil-water separator +solenoidvalvepictures

(Remark:The parts come with manual and automatic control intake two kinds of devices,Through the use of electromagnetic valve,Oil-water separator, such as multiple protection devices, can better to protect equipment. The manual valve is shut while equipment running,Pneumatic aspects through the electromagnetic valve control,Problems arise when the equipment operation environment, pneumatic diaphragm pump will automatically stop working,Effective protection of materials and equipment.

(Pumping speed can be adjusted according to different materials properly, to ensure that the grinding efficiency has always been in the optimal state)

Figure 6: equipment volume regulator images

Remark: As is known to all, the same amount of material in the smaller the space inside the grinding efficiency is higher, the faster the temperature rise will be at the same time,ROOT abandoned the bad practices of many manufacturers design for the constant volume,ROOT’s grinding cylinder head adopts adjustable design concept,When the temperature of the materials, grinding efficiency, cavity pressure changes, can adjust the piston to adjust the temperature of the material, grinding efficiency, cavity pressure,Humanized operation.)

Figure 7: machine voltage regulator for pictures Figure 8: machine sealing pressure constant tank pictures

Remark: We are committed to the customer the machine warranty for three years, is not unfounded, Others often neglected, we pay more attention to.Germany imported mechanical seal with machine seal regulator and pressure constant tank, through the machine voltage regulator and pressure balance can make packer sealing cavity pressure is constant in a fixed pressure, can make full lubrication machine sealing, not because of too much pressure on the machine sealing ring damage.(As is known to all, mechanical sealing of the horizontal sand mill is one of key parts,ROOT abandons the traditional manufacturer directly with water or oil cooling machine sealing method, taking a pressure regulation and refrigerating machine protection device)

Figure 9: piston cylinder cooling equipmentFigure 10: grinding cylinder cooling imagesFigure

Remark: Because the rod pin type sand mill grinding efficiency is higher, so also requires equipment has better cooling systems,ROOT’s sand mill instead of the bad practices of many manufacturers a heavy cooling,ROOT using jacketed, end face, and the hollow shaft triple cooling circulatory system, greatly improving the cooling effect, and real-time display function with temperature,Intuitive understanding of cooling circulating water temperature changes,Internal grinding cylinder with diversion system at the same time, more uniform cooling, cooling effect is better.

Figure 11: dynamic separator images

Remark:ROOT abandons the bad practices of many factories adopt static screen out,ROOT chooses the most advanced dynamic separation, large flow, not blocked;Dynamic separator material selects high wear-resisting ceramics, high hardness, good wear resistance, long service life.Dynamic separator gap can do 0.08 mm, the smallest of fine grinding media can use 0.2 mm in diameter.)

| Packaging Detail:International package with moistureproof OR Wooden case. |

| Delivery Detail:40days |