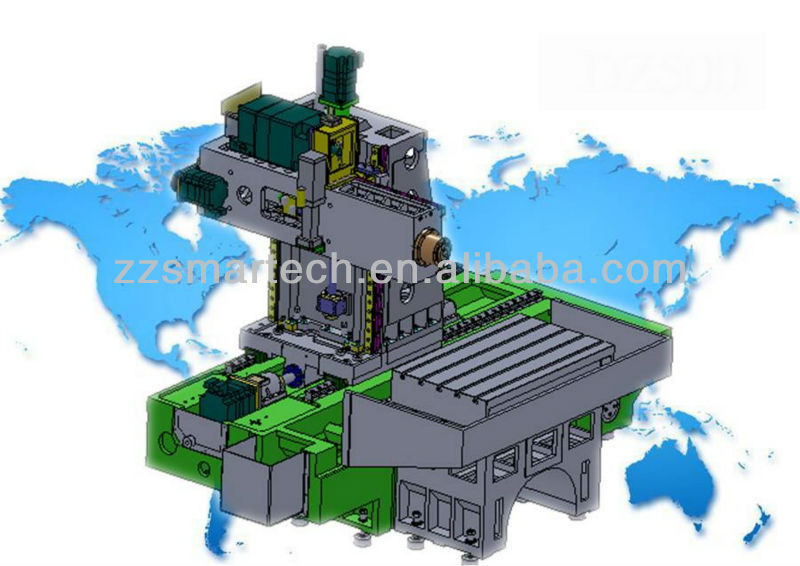

Horizontal Machining Center

| Condition:New | Type:Horizontal | Place of Origin:Yunnan China (Mainland) | Brand Name:SMARTECH |

| Model Number:DZ-500 | Voltage:380 V | Power(W):11-15 kw | Certification:ISO CE |

| moving type:Column moving | speed range:High-speed |

SMARTECH CNC Horizontal Machining Center FRAME

- MACHINE FEATURE:

1 High-class casting by resin sand and wood mould;

2 Top class imported ball screws sets and bearing ;

3 Imported spindle & tool clamping system ;

4 Imported drive connectors ;

5 Stainless steel telescopic protection on X/Y/Z axis ;

6 Central lubrication system ;

7 Coolant system ;

8 X&Y axes Linear slideways and Z axis box way type;

- OPTIONAL:

1 Spindle from Taiwan;

2 Direct drive structure for main motor with spindle ;

3 Central oil coolant for the spindle ;

4 Coolant through spindle ;

5 ATC: drum type, arm type or chain type ;

6 Outside guarding: standard or special made according to clients design

7 Chip conveyor

8 CNC pre-installed for clients: whole full ready package delivery according to clients design

- SPECS:

Item | Unit | ||

Table Size | mm | 1000×760 | |

T-Solt(QTY×Size×Distance) | mm | 3×18×200 | |

Table bearing capacity | kg | 1000 | |

Travel | X Axis | mm | 1050 |

| Y Axis | mm | 640 | |

| Z Axis | mm | 500 | |

Spindle Center to Table Surface | mm | 290~930 | |

Spindle Nose to Table Surface | mm | 170 | |

Spindle Taper/OutsideDia | BT40 | ||

Spindle Speed | r/min | 20~8000 | |

Number of Tools | 24 | ||

Type of Changing tool | Random | ||

Max Tool Diameter | mm(adjacent pots full) | φ77×320 | |

| mm(adjacent pots empty) | φ130×320 | ||

Max Tool Weight | kg | 8 | |

Feed Motors Recommended (X, Y, Z) | N*m | 36,16,16 | |

Spindle Motor | KW | 11/15 | |

Ball Screw Spec. | 50x12 | ||

| 40x10 | |||

1. Linearroller way in all axes to ensure responsive and smooth movement

2. Worktable is fixed on a separated platform, in this way it can handle heavier load without extra load on guides.

3. You might replace the existing worktable with two rotary worktables (to achieve continuous processing), which is much more cost-effective than a pallet exchange system

4. The DZ500 could be dissembled easily, of which you might build a production line.

5. For the sack of compactness and reduce cost for you, the cuttings chute has been well integrated into the frame

6. Pneumaticcounter balance system

7. To attain optimum performance, every chief component has been analyzed with FEM

1. Machining 1). molds of Middle and small size

2). parts of cars, aircrafts

3). Parts of other precision-sensitive machines

2. Parts of 3C products(3C refers to Computer, Communication & Consumter-Electronics)

3. With a rotary table multi-side processing will become possible

| Packaging Detail:Protected by plastic film in wooden pallet, then in a container |

| Delivery Detail:Around 45 days |