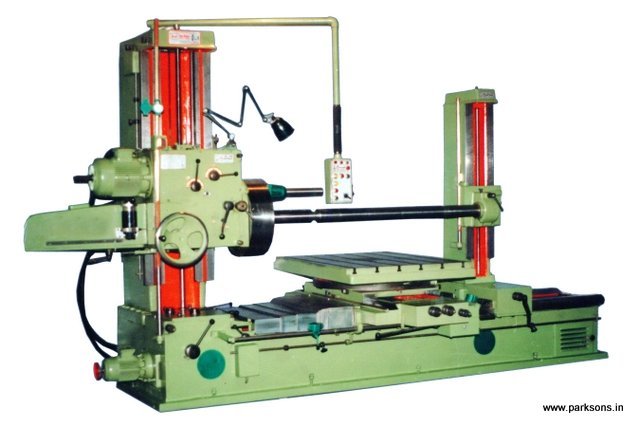

Horizontal Boring Machine

| Condition:New | CNC or Not:Normal | Place of Origin:India | Processing:Boring Machine |

| Precision:Precision | Processing Types:Metal | Workpiece and Weight:Heavy-duty Machine Tool |

Design:

High-powered spindle and face plate drive, Wide range of Spindle speeds & gear box feeds and high precision workmanship allow for high output with the use of high speed Steel as well as Carbide tools.

Fixed Column, built-in Rotary Indexing Table, which also travels transversally, and precise synchronized vertical movement of headstock & boring stay support.

- Hardened & Ground Alloy Steel Working Spindle

- All Gears made of Alloy Steel duly Heat Treated.

- Graded Castings duly seasoned to acquire proper Brinell Hardness in upper range of IS-210 Grade-20/25 i.e. 180-220 BHN.

- High Accuracy of machining due to accurately ground & reliable guideways of Bed & Pillars etc

- Fine positioning by Dial Gauges & Verniers or DIGITAL READOUT SYSTEM

- Heavily ribbed box type Bed & sturdy box type Columns to withstand the heavy cutting force even at elevated height.

- Adjustable stoppers to trip longitudinal & vertical feeds at desired points.

- Fool-proof Safety Clutches & suitable shearing pins are provided for the total safety of the machine

- Conveniently arranged simple control panel system ensures easy operation.

- The machine is manufactured according to Dr. Schlesinger's Acceptance Test Chart.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard Accessories:

One Facing Head duly incorporated with automatic rapid travel arrangement in its facing slide along with facing tool post, 2 Nos. Lubrication Pumps, 5 Nos. Limit switches, working spindle support guide for vibration control, one boring bar, one steel telescopic cover to guard the machine bed, Co-ordinate reading arrangement with scales & Verniers for X,Y,Z,- Axis and with 2 Electric Motors ;- 3H.P. & 1.5H.P. for 65mm boring machine; 5H.P. & 2H.P. for 80mm boring machine; 7.5H.P. & 2H.P. for 100mm boring machine; 10H.P. & 3H.P. for 110mm boring machine & for 125mm boring machine 12.5H.P. & 3H.P. Motors complete with panel board & pendant control for all operations.

Extra Accessories:

Milling Attachment, Taper Boring Attachment, Threading Attachment, 2 axis or 3 axis Digital Readout System 1 micron or 5 micron resolutions, 2.5mm thick Turcite-B linings for the anti-friction movement of sliding parts, One revolving center with 6" True chuck to hold boring bars of different sizes & lengths, Three Nos. Dial Indicators duly fitted in dust proof housings with attachments & one 3 phase electric coolant pump.

| Packaging Detail:Full Wooden Case Packing with Bolt ArrangementFumigation process and Silicon Gel for dehumidification |

| Delivery Detail:4-6 months |