Hopper bottom steel silo for storage wheat and corn

| Condition:New | Capacity:948m3,910t | Material:Steel | Place of Origin:Shandong China (Mainland) |

| Brand Name:TSE | Model Number:TCZK09114 | Model:TCZK09114 | Diameter:9.1m |

| Volume:1182m3 | Eave height:21.165m | Total height:23.290m | Board width:1.12m |

| Layer:14 | Certificate:ISO9001 BV |

Assembly corrugated galvanized

maize storage silo ,silos,the best steel silo

1.What is the application of our silo?

Our silo system are widely used for storage of seeds, flour, feed, cement and chemistry.Used in flour plant and feed mill. we supply soils fundation design/ construction, soils installation and client can rely on our preferctafter-sale service.

2.What is the Features of this assembly silo?

1.Simply installation method: assembly.

2.High percison

3.Good tightness

4.easy maintain

5.service can upto 30 years

6.Less foundation cost, light weight.

7.the silo is made of galvanized steel sheet 275g/m2.350g/m2 and 400g.m2 are options.

8.High degree of standardiazation. We make steel silos as per customer detailed requests

3.What is the Structural outline of this silo?

The structure consists of two parts: The body and the roof.

1. The Silo Body

Include the wall plate, column, manhole, roof ladders and so on.

(1) The wall plate

Our steel is hot galvanized, which makes it durable and weather resistant. Our advanced bolts with spherical washer and the resisting-worn rubber are used to ensure the tightness and using period.

(2) Column

The column, made by the Z-bar, is used to reinforce the silo body. It is connected by junction panels.

(3) Manhole and Roof Ladders

There are inspection door and ladders inside and outside the silo body. It is convenient and accessible for any maintenance work.

2. Roof

Roof is made up of radiated beam, roof cover board, tension ring, ventilator scoop, roof cap, etc.

The space age construction technology, which is adopted in the design of the silo framework, can ensure the stability of silo under the large span. There is a guardrail around the silo eaves and there is also a manhole on top of the roof.

4.What is the specification of the silo?

| Silo type | Hopper bottom silo | Flat bottom silo | |

| Deg.Bottom Cone | 45 degree | 60 degree | |

| Volume | 7.2m3-1855m3 | 8.4m3-701m3 | 39m3-13873m3 |

| Capacity | 5.4t-1428t | 5.8t-755t | 30t-10682t |

| Diameter | 1.8m-11m | 1.8m-7.334m | 3.6m-20.1m |

Accessory Equipment | |||

- Bucket Elevator with capacity from 1 tone/hour to 400 tone/hour - Chain Conveyor with capacity from 1 tone/hour to 400 tone/hour - Screw Conveyor with capacity from 1 tone/hour to 200 tone/hour MACHINES : --Level sensors,aeration system with centrifugal fan,temperature control system and sweep auger ,dedusting system as an option. | |||

5.How the silo manufacture and installed?

Workshop

6.Let's go to the silo site to have a look

7.Do you worry about silo quality?

Commendatory letter we got from customer

ISO9001 and BV Certificate

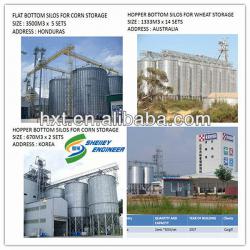

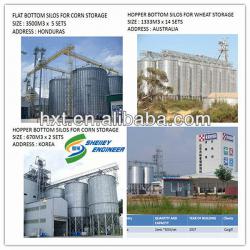

8.Would you like see our silo project we made before?

9.Would you like some other accessory equipment such as conveyor,elevator and so on ?

Clean and dedust system

1, Pre-cleaning sieve Double drum pre-cleaner can effectively clean out light impurities,big impurities,fine impurities etc. from grain;With the inclination angle screen drum and the independent support plus the aspiration device,the pre-cleaner is featured with steady operation and good cleaning effect. The capacity range is 10-200t/h,it is applicable to industries of corn deep-processing,oil and fat,feeding stuff and so on.

2.Suction separator Suction separator is a winnowing device. It’s used for separating light dust. It can be placed both in front of and behind the pre-cleaner.

3.Cyclone is used for clean big dust

And also have some other dedust system, We can supply it accoring to your requirement.

Ventation system

Ventilation for Flat bottom silo Ventilation System includes Natural ventilation vents,Suction Fan,Ventilation Blower,Ventilation channel with net sheets;

Ventilation System includes Natural ventilation vents,Suction Fan,Ventilation Blower,Ventilation net pipe.

10.Do you want the best design proposal? We will design the best appropriate and economical silo proposal.

11.Do you worry about installation on your site?

We can send our engineer to your silo site to guide the silo installation. Our engineer have guided many overseas silo projects.

They are very professional.

If you want to get lower cost and high quality galvanized grain steel silo .Contact us now . We are always here waiting for you!!!!!!

| Packaging Detail:In nude packing |

| Delivery Detail:within 2 months |