HM Pharmaceutical clean room project

| Place of Origin:Zhejiang China (Mainland) | Brand Name:HM PHARMACHINE | Model Number:HM | After-sales Service Provided:Engineers available to service machinery overseas |

| Type:Clean room solution | Application:Pharmaceutical plant/factory | Class:A, C, D |

HM Pharmaceutical clean room project

Usage:provide clean air and suitable temperature, humidity for medicine production.

Clean Room Class:

Class A (100 class), for injection specific area.

Class C (10,000 class), for liquid dosage

Class D (100,000 class), for solid dosage

EPS (Polystyrene) panel, Rock wool panel,

PU (Polyurethane) panel, Paper/Alu. Honeycomb panel

Thickness: 50, 75, 100mm,

Width: 1150mm

1.Panel (or s. s) doors and windows.

2.Floor System: Epoxy self-flow or pvc sheet

3.Air shower or air locks.

4.Pass box

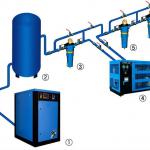

5.HEPA filter and laminar air flow

6.Air supply ducts and air return ducts

7.Air Condition: Air Handling Units and water chiller

8.Lighting fixtures

Performance of sandwich materials in panel

| Core name | Density | Heat conduct | Max temp | Inflammable |

| EPS | ≥18kg/ | ≤0.041w/m.k | ≈100°C | Level B1 |

| Rock wool | ≥18kg/ | ≤0.046w/m.k | ≈500°C | Level A |

| PU | ≥18kg/ | ≤0.030w/m.k | ≈120°C | Level B1 |

ps.: Any requirements or question, pls feel free to send an inquiry or leave a messege to let us known and get more information about the machines.

Why

Us?

We offer professional turnkey project from design till done of the whole project:

- Project consultation

- Conceptual design

- Design

- Factory building

- Clean room and machine manufacturing

- Installation

- Commissioning

- Training

- Assist validation and production

- Customer’s project works well...

All kinds of pharmaceutical machines can be suplied, such as:

- Tablet press machine

- Capsule filling machine

- Vila line

- Ampoule line

- Fluid bed dryerFreeze dryer(lyophilizer)

- Blister and cartoning line

- Cleaning room

- Sterilizer

- Washing machine

- Tank

- Tablet coating machine

- Candy coating machine

- Candy pillow-type packing machine

- Granulator

- Tube filing and filling machine

- etc.

Professional team at the working site:

HM PHARMACHINE provides pharmaceutical machines, laboratory instruments and professional turn-key project, high quality, economical price!

Supported with European technology, cooperating with worldwide professional team, machines and projects that we supplied match up international regulations well, like EU cGMP, USA FDA, WHO GMP, UK MHRA, Australian TGA, etc.

Integrated with HM Combines Swiss Technology, Brand and China manufacturing, HM Swiss offers EUcGMP Concept Design, validation service, Clean room Monitoring system, software program updated, while HM in China focuses on detail design of project, Europe standard machines, top clean room system, top sanitary pipe system, whole project management. Machines we supplied have HM standard & Own manufacturing, and supported with more than 30 OEM factories under quality control of HM.

With complete and professional engineers and engineering team, HM PHARMACHINE avoids conflict between different professions and suppliers, to get high efficiency and quality in project, save time and cost.

| Packaging Detail:Suitable for sea transportation. |

| Delivery Detail:60 days |