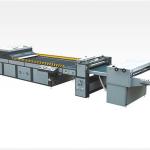

High Speed Type film coating machine

| Type:Coating Machine | Product:coating machine | Machine material:Iron or Cast Iron | Machine appearance color:white grey |

| Safety and durability:High Grade | Production Place:Ruian Wenzhou | Attached Accessories:Some electronic part , metal parts and hardware tool will be attached. | Custom:Customer can chose the configurations by yourself |

| Technical Training:Our engineer can go to your factory to do technical training | Industry Experience:Our engineers have 25years experience in machinery this industry | Overseas Sales Center:Indonesia ,Philippines |

High Speed Type film coating machine

Buyer reading of coating machine:

Thanks for noting this , In order you to find the ideal machinery , Please tell us the bag you want to make ,or the material you will use when you send us the quotation.This can save you a lot of time ,kindly understand it.

About us:

We not only sell the machine , but also do the most important thing:"To make sure the machine work smoothly in foreign country." this is our responsibility to customer.

In the past 15 years. we help a lot of customer establish soft packing and cement bag factory around the world.Offer ideal equipment for them ,acquire good reputation cause quality machine and afte-sales service.

FUNCTION&FEATURE of coating machine :

1.Coating and laminating are adopt dual frequency converter, more stable operating

2.Dry oven tension adopt automatic pressure sensor controller

3.The first unwinder adopts photoelectric correcting controller , The second unwinder adopts up and down double location.

4.Triple open-top electric oven

5.Laminating and coating are adopt cylinder press fit

6.Unwind adopts automatic clutch control the tension

Main Technical Parameters of coating machine

| Laminating material | BOPP .PET .CPP .Aluminum foil paper |

| Mechanical speed | 160m/min |

| Max.unwind/rewind diameter | φ600mm φ800mm |

| Tension Control Way | Four motors closed_loop tension control |

| Moving Material Way | Automatic deviation corrector LPC |

| Receiving Material Way | Winding automatic receive material |

| Drying Way | Four parts closed oven |

| Oven length | 9750mm |

| Max Laminating width | 800mm, 1000mm, 1250mm, 1300mm, |

View more Picture of Dry Laminating Machine:

Machine using in indonesia customer factory:

Unwinding process:

Winding process:

Aluminum Foil Process:

Correction Device:

Our Service

1.Installation Services

Installation Services are available with all new machine purchases. We will provide the technical know-how for your operation smooth transition and support for installing, debugging, operation of the machine, it will indicate you how to use this machine well.

2.Clients Traning Services

We can train your staff to use your film blowing equipment systems properly. It means that we offer Customers Training, teaching how to use the systems most efficiently and safely as well as how to maintain optimal operational productivity.

3.After Sales Service

We offer the Preventative Maintenance and After Sales Service. For we strongly feels about the importance of supporting our customers and the product solutions we provide. Consequently we offer comprehensive maintenance options to prevent equipment issues before they become problems. Also we offer one year guarantee period.

| Packaging Detail:1.Bottom: composite material pallets2.Machine Outside:waterproof film cover the machine ,then cover a waterproof fabric on the High Speed Plastic Film Roll Dry Type Coating Machine.3.The whole machine will be loaded into a Large wooden cases before load into the container.4.Attached Accessories will be load into a small wooden case in the container |

| Delivery Detail:30-45days After getting Deposit Or The L/C documents |