High quality wood chips dryer

| Condition:New | Type:Drum Drying Equipment | Place of Origin:Henan China (Mainland) | Brand Name:GHM |

| Certification:ISO9001-2008 | Warranty:one year | After-sales Service Provided:Engineers available to service machinery overseas | name:High quality composite dryer for wood chips |

High quality dryer for wood chips

Introductions:

It is professionally designed for drying different kinds of wood sawdust. It has advantages

of low cost, low consumption, high capacity, easy to operation and maintain, etc. In addition,

the round places of pipes can be changed to any angle which can save space and solve plant

dimension limitation.All of round places can be adjusted to any angle of 360 centigrade degree

according to operation request. Clients can change the angle of dryer base on the production field.

Raw materials: It suitable for dry the grain, sawdust, etc, small granular materials, It dry quickly

and higher capacity.

Main details:

For raw materials with heavy humidity which is above 12%, you need to install a Dryer before

further processinRegarding GHM ,IT is suitable to process materials which moisture content

between 35%-50%.It can reduce the humidity to 8-12% one drying time. That means it can reduce approx.30% for one drying time. But if the

humidity of materials is lower than 35%, the capacity will be increased with less of fuel

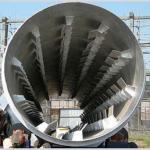

Working Principle of rotary dryer

Material to be dried enters the dryer, and as the dryer rotates, the material is lifted up by a series of internal fins lining the inner wall of the dryer. When the material gets high enough to roll back off the fins, it falls back down to the bottom of the dryer, passing through the hot gas stream as it falls. This gas stream can either be moving toward the discharge end from the feed end (known as co-current flow), or toward the feed end from the discharge end (known as counter-current flow). The gas stream can be made up of a mixture of air and combustion gases from a burner, in which case the dryer is called a direct heated dryer. Alternatively, the gas stream may consist of air or another (sometimes inert) gas that is preheated. When the gas stream is preheated by some means where burner combustion gases do not enter the dryer, the dryer known as an indirect-heated type. Often, indirect heated dryers are used when product contamination is a concern.

Technical parameters:

| Model (mm) | Inclination (%) | Rotate speed (r/min) | Air inlet temperature (°C) | Power (kw) | Production capacity(t/h) | Weight (t) |

| 600x6000 | 3-5 | 3-8 | ≤700 | 3 | 0.5-1.5 | 2.9 |

| 800x8000 | 3-5 | 3-8 | ≤700 | 4 | 0.8-2.0 | 3.5 |

| 800x10000 | 3-5 | 3-8 | ≤700 | 4 | 0.8-2.5 | 4.5 |

| 1000x10000 | 3-5 | 3-8 | ≤700 | 5.5 | 1.0-3.5 | 5.6 |

| 1200x10000 | 3-5 | 3-8 | ≤700 | 7.5 | 1.8-5 | 14.5 |

| 1200x12000 | 3-5 | 3-8 | ≤700 | 11 | 2-6 | 14.8 |

| 1500x12000 | 3-5 | 2-6 | ≤800 | 15 | 3.5-9 | 17.8 |

| 1800x12000 | 3-5 | 2-6 | ≤800 | 18 | 5-12 | 25 |

| 2200x12000 | 3-5 | 1.5-6 | ≤800 | 18.5 | 6-15 | 33 |

| 2200x18000 | 3-5 | 1.5-6 | ≤800 | 22 | 10-18 | 53.8 |

| 2200x20000 | 3-5 | 1.5-6 | ≤800 | 30 | 12-20 | 56 |

| 2400x20000 | 3-5 | 1.5-5 | ≤800 | 37 | 18-30 | 60 |

| 3000x20000 | 3-5 | 1.5-5 | ≤800 | 55 | 25-35 | 78 |

| 3000x25000 | 3-5 | 1.5-5 | ≤800 | 75 | 32-40 | 104.9 |

| Packaging Detail:sawdust dryer with standard package |

| Delivery Detail:in 15 days after your payment |