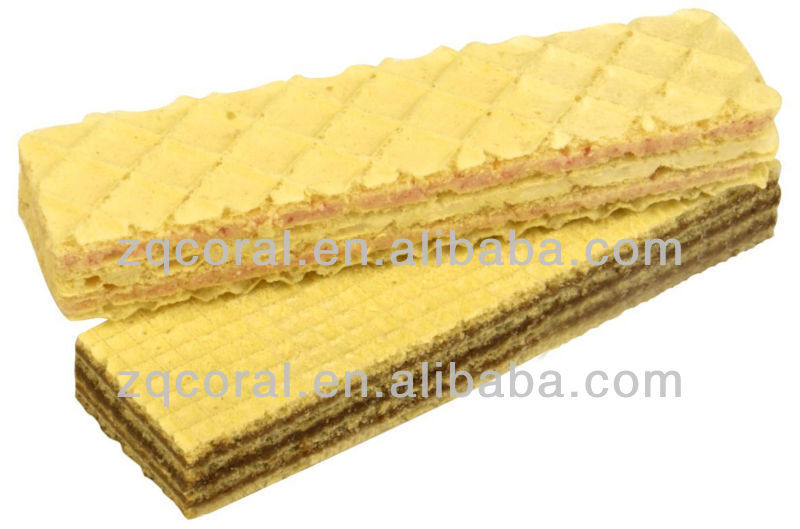

High-quality wafer biscuit bakery oven

| Condition:New | Place of Origin:Guangdong China (Mainland) | Brand Name:CORAL | Model Number:SHR Series |

| Usage:Biscuit | Type:Wafer Baking Oven | Power Source:Gas | Voltage:380V 50HZ |

| Certification:CE Certificate | 1.Bearing:SKF France | 2.Motor:SEW Germany | 3.Program:Mitsubishi |

| 4.Buttons:Schneider Germany | 5.Sanitation:hygiene standard |

1.Profile Introduction

We design and manufacture of an exclusive machines and equipment for producing superior quality wafer production line,which is complied with food hygiene standard. It consists of baking oven,cooling tower,sheet picking machine,cream spreading machine,cooling cabinet,cutting machine,batter mixer,cream mixer and smash machine.

Our production line can run in stable performance. The driven motors adopt SEW Germany, the bearings use SKF Fracne. Operating system uses PLC programing make the production automated and easy control.

2 Wafer baking inside Tunnel Baking Oven

Batter is automatically given onto baking plates as premature setting.Baking plate can lock and open as running on the rail.

-Control panel: Japan Mitsubishi touching screen

A. control the preset and actual temperature on the touch screen

B. digital dispalys for temperatures and number of wafer sheets per minute

C. display / control /adjustment of the baking plate transporting speed and batter deposited status

Combustion System

-Automatic top and bottom burner system with high voltage ignition

-Gas-safety device with main gas valve.filter.pressure regulator,gas pressure switch,air pressure switch,manometers and shut-off valves

-Combustion air fan for feed of the combustion

-Automatic temperature control system with radiation

-Probe in order to check the tempratures at baking plates

3.Automatic sheet take-off unit:

-With turn wheel and extraction conveyor,

-With rotating brush for cleaning on wafer sheet

-Mounted with brush to remove waste on wafer sheet

-Cover adopts 304 stainless steel

-Imported transmission belt

4. Detailed Technical Parameters for each complete line:

| Model Plates | Capacity (Tons) | Power (KW) | LPG Consumption (Kg/H) | Natural Gas Consumption (M3/H) | Compressor Air Consumption | Baking Plate Size (MM) | Cutting Size (MM) | Dimension (L×W×H) (Meters) | Weight (Tons) |

| 27 | 2.0 | 39.168 | 13 | 20-30 | 0.9 M3/Min 0.8Mpa | 470×325 | 455×315 | 23.6×2.0×2.5 | 15.0 |

| 33 | 3.0 | 39.868 | 15 | 20-30 | 24.7×2.0×2.5 | 15.5 | |||

| 39 | 3.5 | 42.868 | 19 | 20-30 | 25.8×2.0×2.5 | 16.0 | |||

| 45 | 4.0 | 42.868 | 23 | 30-33 | 27.0×2.0×2.5 | 19.0 | |||

| 51 | 4.5 | 42.868 | 27 | 35.4-38.4 | 28.0×2.0×2.5 | 21.0 | |||

| 65 | 6.0 | 43.668 | 32 | 44.1 | 31.0×2.0×2.5 | 26.0 | |||

| 75 | 7.5 | 50.000 | 37 | 54.0 | 32.7×2.0×2.5 | 29.0 |

About us:

Coral Foodstuff Machine Co., Ltd. -- China food machinery supplier, was established in 2002. It is one of China's large sacled companies specializing in automatical wafer production line. By using of engineers and technicians' professional knowledge and rich experience, combined with various international brand machinery components, our company can manufacture automatic wafer production line with many advantages of reliable performance, high yield, low power, convenient maintenance, easy operation, no environmental pollution, etc, and receives good reputation from customers.

Our Certificates

| Packaging Detail:Standard packing in container for seaworthy |

| Delivery Detail:90 days |