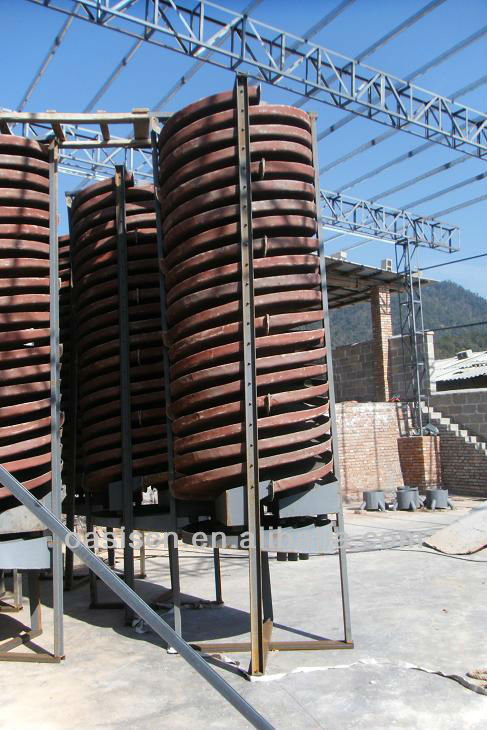

high quality Gravity mining equipment spiral chute separator Spiral Chute

| Type:Leaching Tank | Condition:New | Place of Origin:Jiangxi China (Mainland) | Brand Name:oasis |

| Model Number:5LL | Certification:ISO | color:As per your requirement |

Spiral Chute, Spiral Concentrator

Products Description

1.High efficiency

2.Easy operation

3.Energy saving

4.Reliable structure, resonable design

DescriptionsSpiral concentrator is our company's concentrating experienced scientific product, which is the best concentrating equipment, especially for concentrating sand ore in beach, riverside, seashore and stream. The product is made of the fiberglass lined with wear-resistant polyurethane and corundum cover; the advantages are light, moisture proof, anti-rust, wear proof, anti corrosion and no noise, properly suitable for the different feeding particle sizes and grades. It is the domestic advanced level, the new highly effective equipment.

ApplicationsIt has been used in to enrichment the particle size 0.3-0.02 millimeters fine grain like iron, tin, chromite, ilmenite, tungsten, zinc, tantalum-niobium, gold, coal , monazite, rutile, zircon and other low-grade ores. The non-metallic minerals which have a big enough specific gravity difference.

Features1. Reasonable structure and small occupation area 2. High recovery, high efficiency, and precise separation 3. Non-required power 4. Light in weight, anti corrosion, rust and wear resistant 5. Simple installation and Minimal maintenance requirements 6. Low operating cost and long working life 7. Reliable running with minimal operator attention 8. Strong adaptability to fluctuation of feeding amount, density, size and grade 9. The surface of corundum forms strong friction the concentration effect surpass plastic surface

Technical Specificationsour company uses the newest design and a complete set of technology organization produced and strict quality testing to guarantee each specification of spiral separator qualified. We make the serialized with a special kind of grooved spiral separator to be selected by colored, ferrous metal mine, coal chemical industry, coal dressing, sulfur factory as well as the scientific research, the design department, the colleges and universities test chamber.

Technical parameters

| Specification | 5LL-1500 | 5LL-1200 | 5LL-900 | 5LL-600 | 5LL-400 | |

| Spiral Diameter (mm ) | 1500 | 1200 | 900 | 600 | 400 | |

| Spiral Pitch (mm ) | 720/540 | 900/720 /540 | 675/540 /405 | 450/360 /270 | 240/180 | |

| Ratio of Pitch To Diameter | 0.48/0.36 | 0.75/0.6 /0.45 | 0.75/0.6 /0.45 | 0.75/0.6 /0.45 | 0.6/0.45 | |

| Lateral Obliquity | 9° | 9° | 9° | 9° | 9° | |

| Starts | 4 | 4 | 4 | 3 | 2 | |

| Feeding Sizes (mm ) | 0.8-0.037 | 0.3-0.03 | 0.3-0.03 | 0.2-0.02 | 0.2-0.02 | |

| Feeding Density (%) | 30-60 | 25-35 | 25-55 | 25-55 | 25-55 | |

| Capacity (t/h ) | 6-8 | 4-6 | 2-3 | 0.8-1.2 | 0.15-0.2 | |

| Dimension (mm ) | Length | 1600 | 1360 | 1060 | 700 | 460 |

| Width | 1600 | 1360 | 1060 | 700 | 460 | |

| Height | 5300 | 5230 | 4000 | 2600 | 1500 | |

| Weight (kg ) | 800 | 600 | 400 | 150 | 50 | |

| Packaging Detail:standard container. The goods would be processed to be rustproof and moisture proof before delivery. The small parts are packed into wooden box. |

| Delivery Detail:7-30days |